2025/07

Understanding HIPS Sheet Co-Extruders: Essential Insights for the Manufacturing Industry

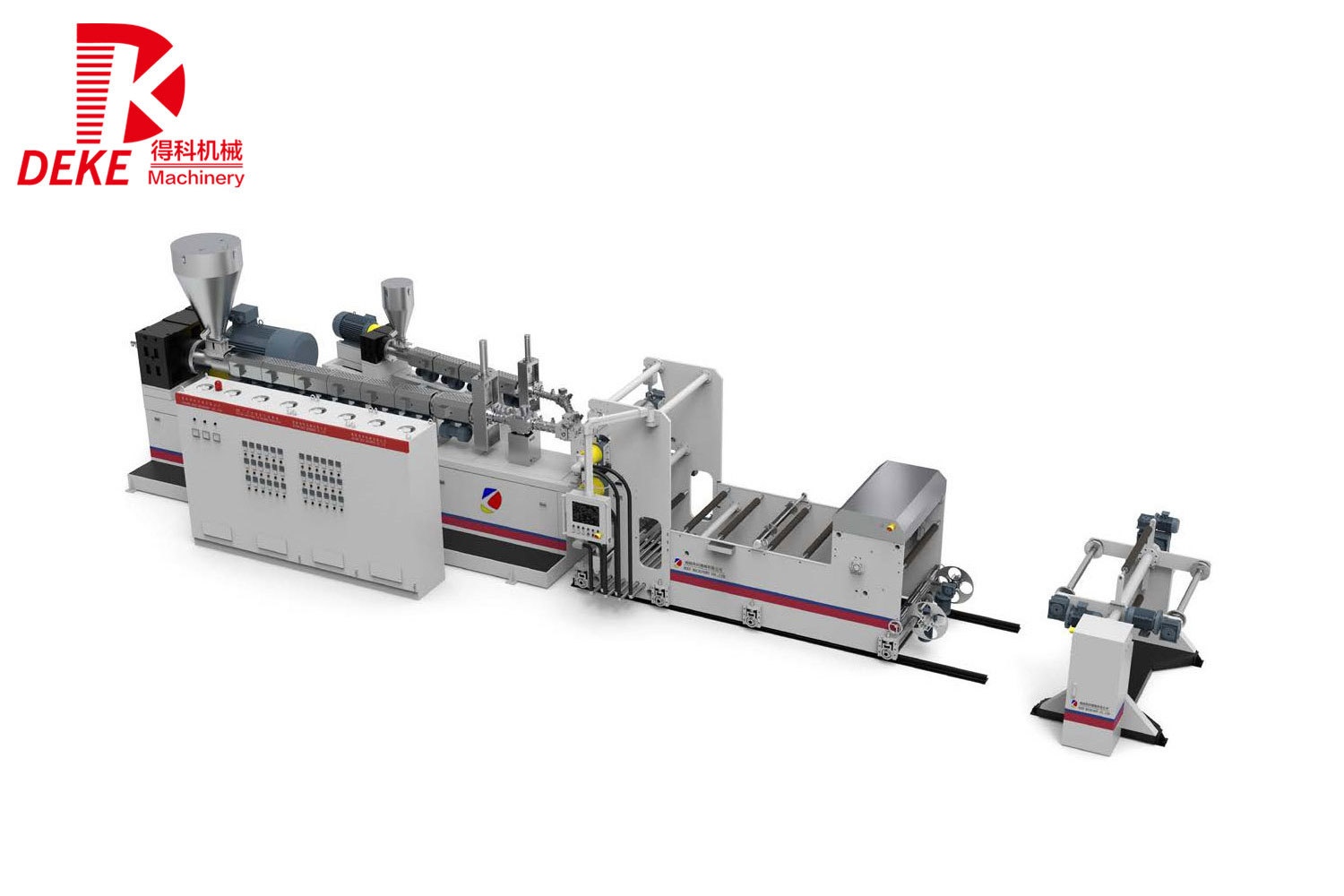

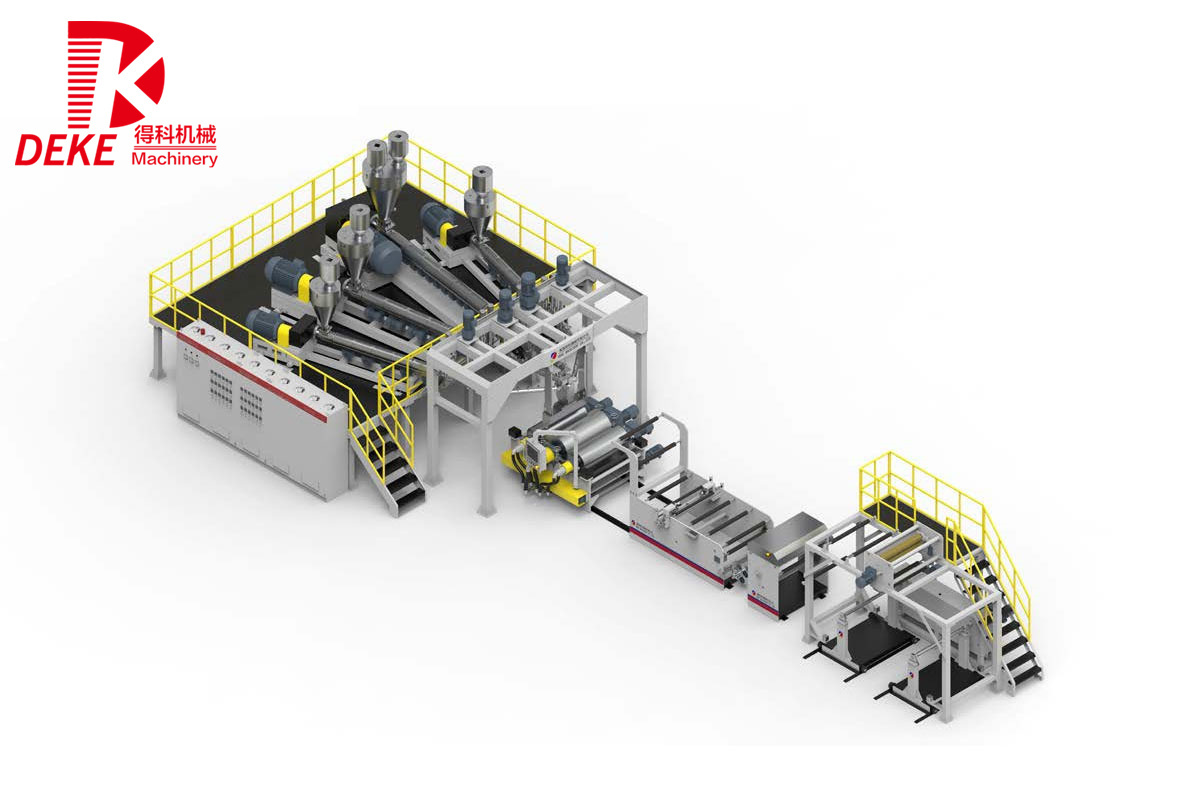

In the realm of plastic processing machinery, HIPS (High Impact Polystyrene) sheet co-extruders play a crucial role in producing high-quality plastic sheets. These machines utilize a co-extrusion technique, allowing for the simultaneous extrusion of multiple layers of different materials. This innovative approach not only enhances the properties of the final product but also offers manufacturers t

2025/07

A Comprehensive Guide to HIPS Sheet Co-Extruder Technology In the dynamic landscape of plastic manufacturing, understanding **HIPS sheet co-extruder technology** is crucial for optimizing production processes and enhancing product quality. This guide will explore the intricacies of co-extrusion, its advantages, applications, and the technical aspects that every manufacturer should know. Table of

2025/07

Unlocking the Potential of HIPS Sheet Co-Extruder Technology in Plastic Manufacturing

In the dynamic field of plastic manufacturing, the HIPS (High-Impact Polystyrene) Sheet Co-Extruder has emerged as a transformative solution, particularly for businesses focused on producing high-quality plastic sheets. This technology enables the simultaneous layering of different materials, which can significantly enhance the physical properties of the final product. By understanding how to leve

2025/07

Exploring the Benefits of HIPS Sheet Co-Extrusion for Your Production Line

Exploring the Benefits of HIPS Sheet Co-Extrusion for Your Production Line Table of Contents 1. Introduction to HIPS Sheet Co-Extrusion 2. What is HIPS (High Impact Polystyrene)? 3. The Co-Extrusion Process Explained 4. Advantages of HIPS Sheet Co-Extrusion 4.1 Enhanced Product Quality 4.2 Cost Efficiency 4.3 Increased Production Speed

2025/07

Understanding HDPE Sheet Extruders: Key Insights for Professionals

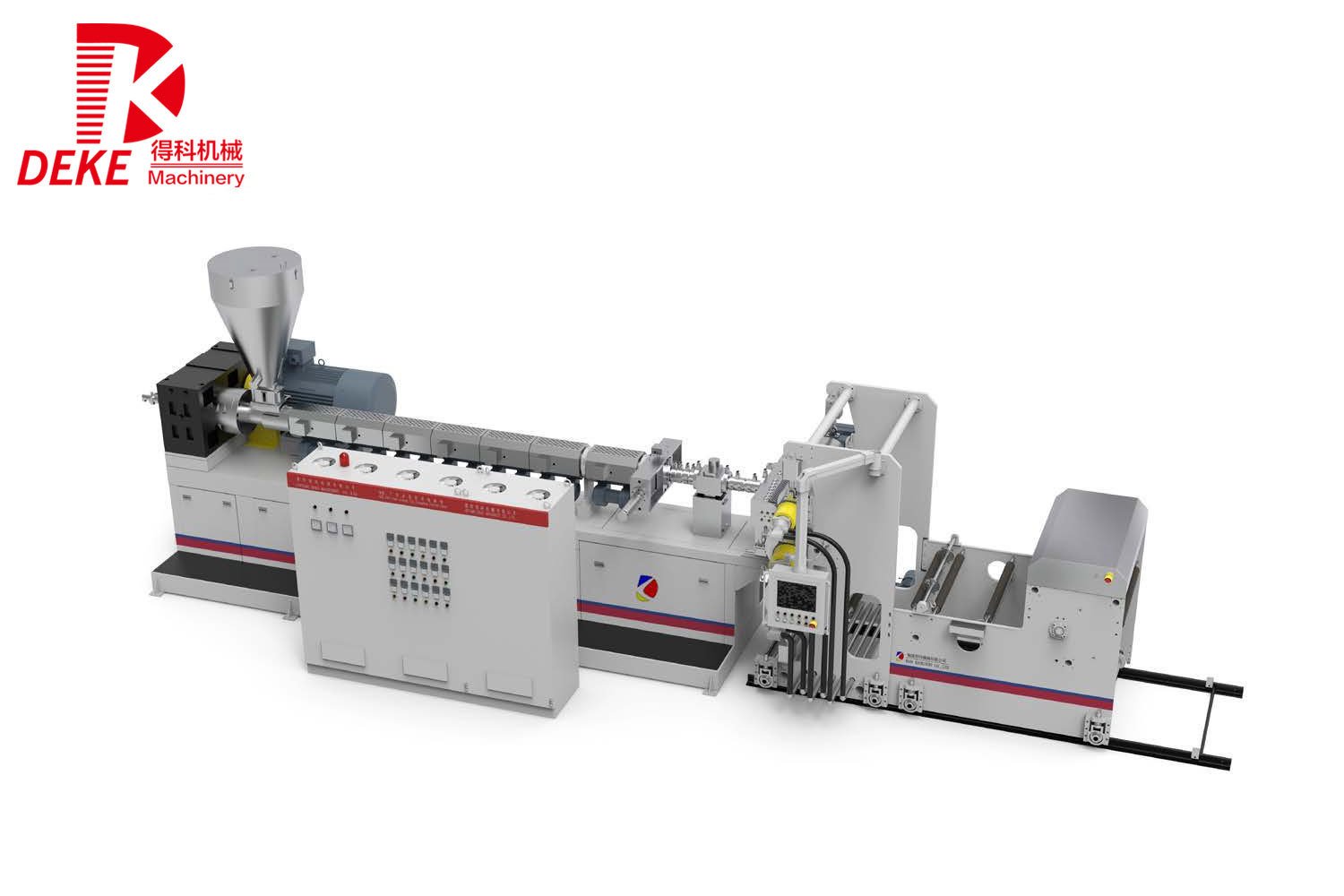

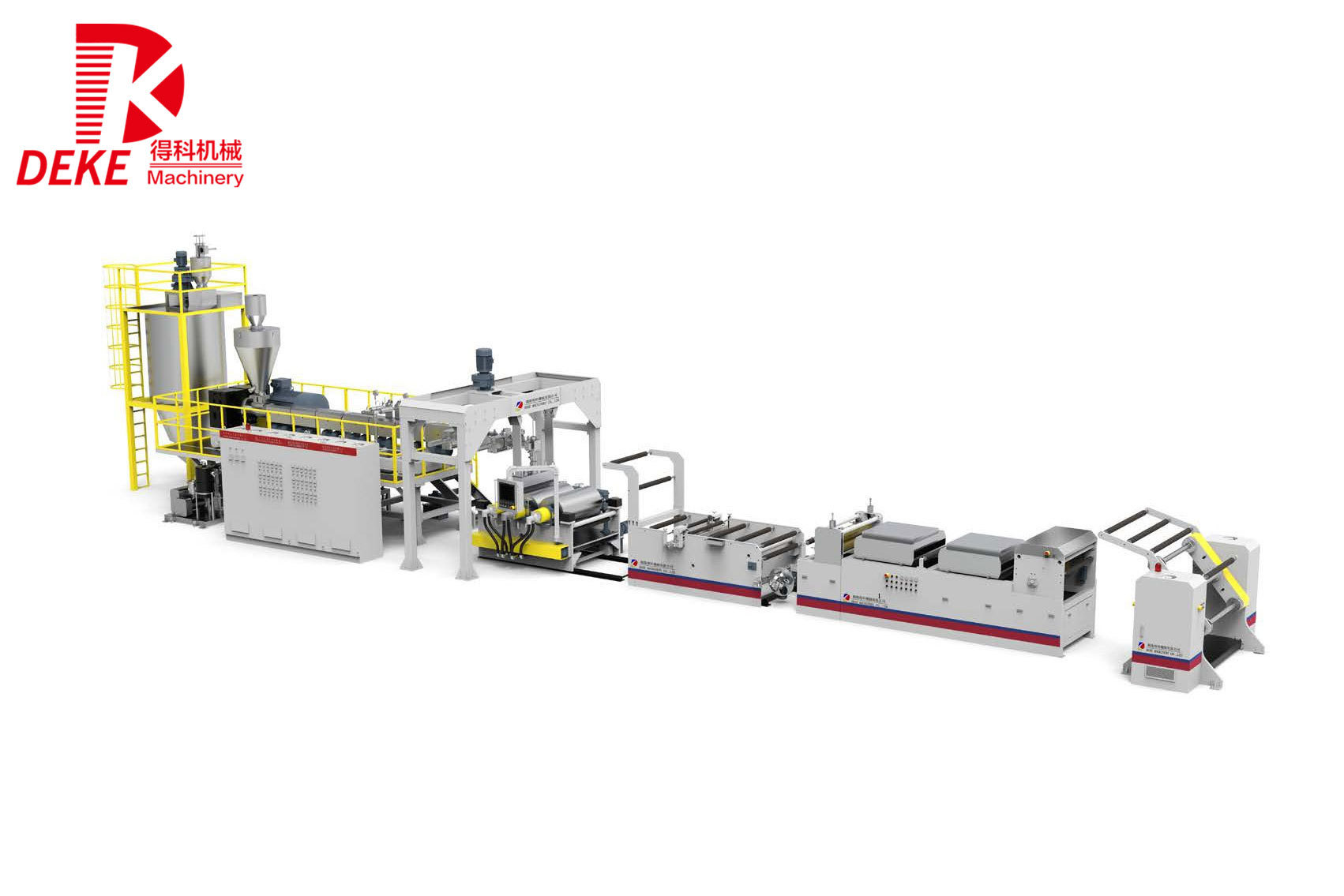

High-Density Polyethylene (HDPE) sheet extruders are integral to the plastic processing industry, particularly in the manufacture of various HDPE products. These machines are designed to produce sheets of HDPE through a process known as extrusion, where plastic pellets are heated, melted, and then forced through a die to form continuous sheets. Understanding the functionality and advantages of HDP

2025/07

Exploring the Global Market for HDPE Sheet Extruders: Trends, Insights, and Future Prospects

Exploring the Global Market for HDPE Sheet Extruders Table of Contents Introduction to HDPE Sheet Extruders Market Overview and Growth Potential Key Drivers of the HDPE Sheet Extruder Market Challenges Facing the HDPE Sheet Extrusion Industry Technological Advancements in HDPE Extrusion Regional Market Insights Competitive Landscape and Key Players Future Outlook f

2025/07

Understanding HDPE Sheet Extruders: A Comprehensive Guide for Manufacturers

HDPE sheet extruders are critical machines in the plastic processing industry, specifically designed to produce high-density polyethylene (HDPE) sheets. These sheets are widely used across various applications such as packaging, construction, and automotive industries due to their durability, chemical resistance, and lightweight properties. Understanding the mechanics and benefits of HDPE sheet ex

2025/07

How HDPE Sheet Extruders Contribute to Waste Reduction and Sustainable Manufacturing

Introduction to HDPE Sheet Extruders and Their Environmental Impact The quest for environmental sustainability is more pressing than ever, especially in the realm of manufacturing. As industries increasingly adopt eco-friendly practices, **HDPE sheet extruders** emerge as pivotal players in reducing plastic waste and promoting recycling. High-Density Polyethylene (HDPE) is a robust plastic with di

2025/06

Understanding PLA Sheet Extrusion Lines: A Comprehensive Guide to Plastic Processing Technology

PLA (Polylactic Acid) sheet extrusion lines are pivotal in the realm of plastic processing machinery, particularly for the production of biodegradable and environmentally friendly plastic products. As industries increasingly prioritize sustainability, the demand for PLA materials has surged, making understanding the extrusion process essential for manufacturers. The core function of a PLA sheet ex

2025/06

Essential Components of a High-Performance PLA Sheet Extrusion Line

Essential Components of a High-Performance PLA Sheet Extrusion Line When it comes to the production of biodegradable plastics, particularly Polylactic Acid (PLA), the efficiency and performance of the extrusion line play a critical role in achieving high-quality output. Understanding the essential components of a high-performance PLA sheet extrusion line enables manufacturers to optimize their pro

RELATED INFORMATION

Understanding PET Sheet Extruder Machines: A Comprehensive Guide

PET sheet extruder machines are specialized equipment used in the plastic processing industry to produce sheets made from polyethylene terephthalate (PET). These machines play a crucial role in various applications, including packaging, automotive parts, and consumer goods. Understanding how these machines work, their components, and their applications can help manufacturers improve efficiency and

Exploring the Efficiency of PET Single Screw Extruders in Manufacturing

Exploring the Efficiency of PET Single Screw Extruders in Manufacturing Table of Contents 1. Introduction to PET Single Screw Extruders 2. The Importance of PET in the Manufacturing Process 3. Design and Mechanism of Single Screw Extruders 4. Efficiency Factors of PET Single Screw Extruders 5. Applications of PET Single Screw Extruders in Manufacturing 6. Maintenance and O