Unlocking the Potential of HIPS Sheet Co-Extruder Technology in Plastic Manufacturing

2025-07

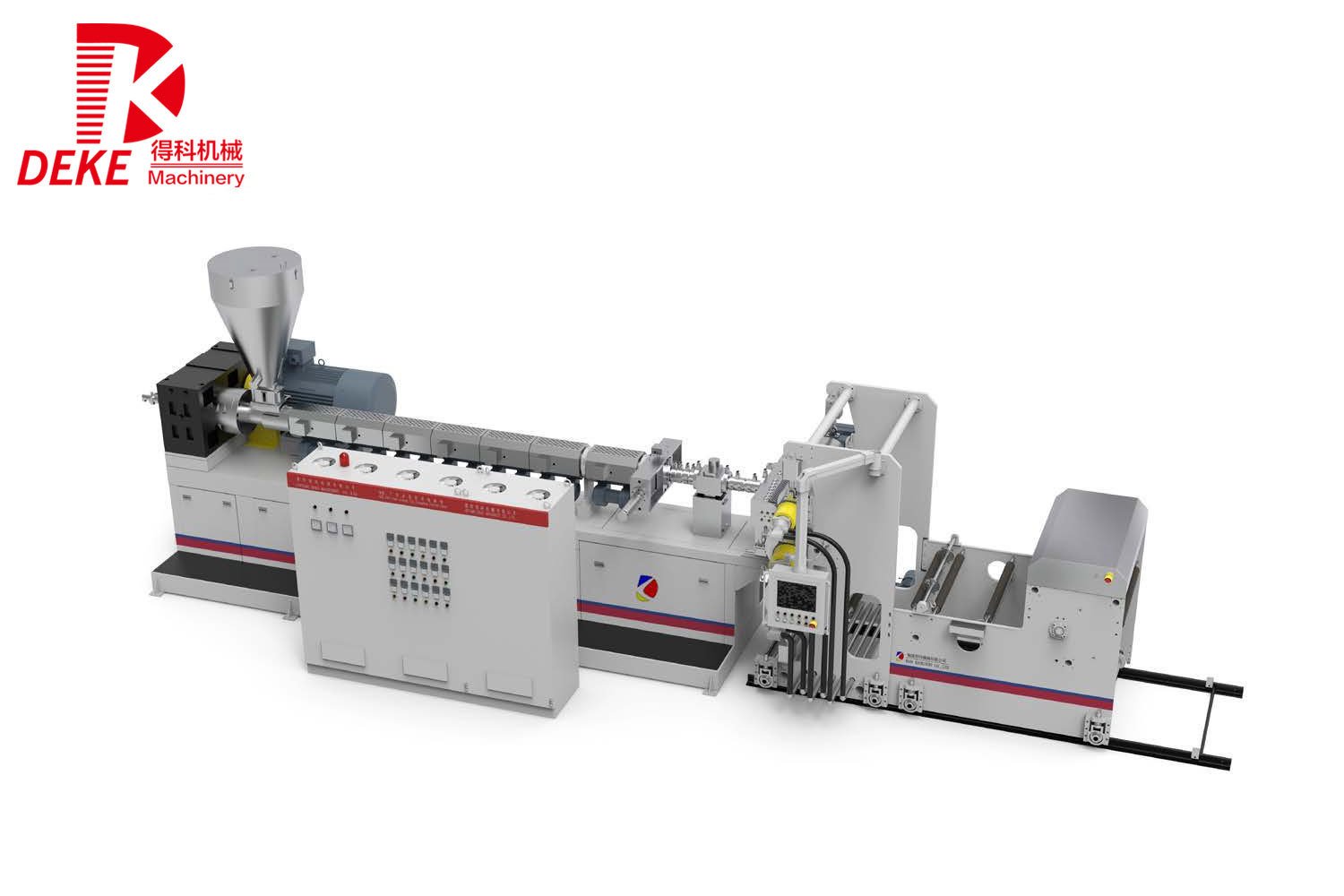

One of the primary advantages of utilizing a HIPS Sheet Co-Extruder is the ability to create multi-layered sheets that offer superior strength and impact resistance. This characteristic is crucial for applications that require durability, such as in the packaging, automotive, and construction industries. With the ability to co-extrude HIPS with various materials, manufacturers can tailor the properties of the final product to suit specific requirements, thus expanding their application range.

In addition to enhancing product performance, the HIPS Sheet Co-Extruder can streamline production efficiency. By integrating multiple processes into a single operation, this equipment reduces the need for additional machinery, thereby lowering capital investment and operational costs. Moreover, the ability to produce sheets with different surface finishes and colors in one pass can significantly decrease lead times and increase productivity, enabling manufacturers to respond swiftly to changing market trends.

Another noteworthy benefit of HIPS Sheet Co-Extruder technology is its capacity for sustainability. As environmental concerns rise, manufacturers are increasingly seeking ways to incorporate recycled materials into their production processes. The co-extrusion process can facilitate the use of recycled plastics, helping companies reduce waste and promote eco-friendly practices. This not only aligns with global sustainability goals but also enhances the brand reputation among environmentally conscious consumers.

Furthermore, maintenance and operation of HIPS Sheet Co-Extruder systems are designed to be user-friendly, allowing operators to efficiently monitor and adjust parameters to ensure optimal performance. Training programs and resources are often available to aid staff in mastering the technology, which ultimately contributes to a more skilled workforce and better overall production outcomes.

In conclusion, adopting the HIPS Sheet Co-Extruder technology is a strategic move for manufacturers aiming to enhance their offerings within the competitive plastic processing landscape. By focusing on product quality, operational efficiency, and sustainability, businesses can leverage this advanced technology to not only meet but exceed customer expectations, securing their position in the market. Embracing this innovation could very well be the key to unlocking significant growth and success in the plastic manufacturing sector.

Previous Page:

RELATED INFORMATION

Understanding PET Sheet Extruder Machines: A Comprehensive Guide

PET sheet extruder machines are specialized equipment used in the plastic processing industry to produce sheets made from polyethylene terephthalate (PET). These machines play a crucial role in various applications, including packaging, automotive parts, and consumer goods. Understanding how these machines work, their components, and their applications can help manufacturers improve efficiency and

Exploring the Efficiency of PET Single Screw Extruders in Manufacturing

Exploring the Efficiency of PET Single Screw Extruders in Manufacturing Table of Contents 1. Introduction to PET Single Screw Extruders 2. The Importance of PET in the Manufacturing Process 3. Design and Mechanism of Single Screw Extruders 4. Efficiency Factors of PET Single Screw Extruders 5. Applications of PET Single Screw Extruders in Manufacturing 6. Maintenance and O