Understanding HIPS Sheet Co-Extruders: Essential Insights for the Manufacturing Industry

2025-07

One of the primary advantages of using a HIPS sheet co-extruder is its ability to produce sheets with varying properties without the need for separate processes. By combining different polymers, manufacturers can enhance features such as impact resistance, UV stability, and surface finish, resulting in a product that meets diverse application needs. For instance, HIPS sheets are widely used in the packaging industry due to their excellent strength-to-weight ratio and ability to be easily fabricated.

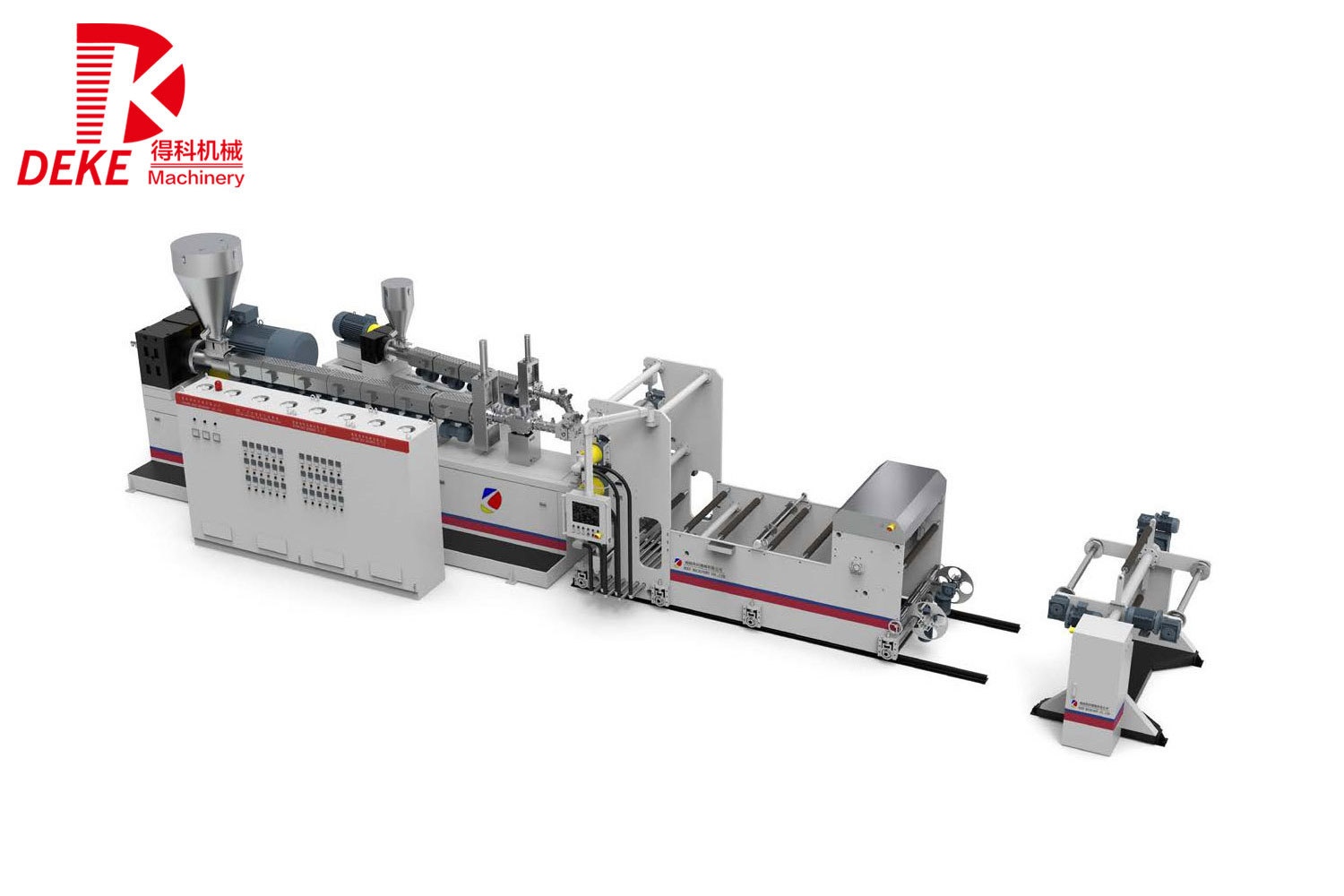

The co-extrusion process begins with the preparation of raw materials, which are fed into the extruder. The machine is equipped with multiple extruder barrels, each responsible for melting and conveying a different polymer. As the materials exit the die, they form a multilayer sheet, with each layer contributing its unique properties to the final product. This process not only improves efficiency but also reduces material waste, making it a cost-effective solution for manufacturers.

Another significant benefit of HIPS sheet co-extruders is their adaptability to various production scales. Whether you're operating on a small scale or a large industrial setting, these machines can be configured to meet your production demands. Additionally, advancements in technology have led to enhanced automation features, allowing for greater precision and control over the extrusion process. This not only improves the consistency of the products but also streamlines production, reducing downtime and increasing throughput.

In terms of applications, HIPS sheets produced through co-extrusion find uses in multiple industries, including automotive, consumer goods, and construction. Their versatility makes them ideal for applications ranging from interior components in vehicles to packaging for food products. Moreover, with the growing emphasis on sustainability, manufacturers are increasingly exploring the use of recycled materials in conjunction with HIPS in the co-extrusion process, contributing to a more environmentally friendly production cycle.

In conclusion, HIPS sheet co-extruders represent a vital component of modern plastic processing machinery, offering enhanced performance, versatility, and efficiency. By understanding the intricacies of these machines, industry professionals can better leverage their capabilities to produce high-quality products that meet the evolving demands of their respective markets. Whether you are looking to enhance product properties or optimize production processes, HIPS sheet co-extruders provide innovative solutions to drive your manufacturing success.

RELATED INFORMATION

Understanding PET Sheet Extruder Machines: A Comprehensive Guide

PET sheet extruder machines are specialized equipment used in the plastic processing industry to produce sheets made from polyethylene terephthalate (PET). These machines play a crucial role in various applications, including packaging, automotive parts, and consumer goods. Understanding how these machines work, their components, and their applications can help manufacturers improve efficiency and

Exploring the Efficiency of PET Single Screw Extruders in Manufacturing

Exploring the Efficiency of PET Single Screw Extruders in Manufacturing Table of Contents 1. Introduction to PET Single Screw Extruders 2. The Importance of PET in the Manufacturing Process 3. Design and Mechanism of Single Screw Extruders 4. Efficiency Factors of PET Single Screw Extruders 5. Applications of PET Single Screw Extruders in Manufacturing 6. Maintenance and O