2025/07

Why Choosing a Twin Screw Compounder Can Transform Your Plastic Manufacturing

Why Choosing a Twin Screw Compounder Can Transform Your Plastic Manufacturing Manufacturing in the plastic industry involves intricate processes that require precision, efficiency, and innovation. Among the various technologies available, the twin screw compounder stands out as a transformative solution that can redefine how plastic products are made. This article delves into the numerous advantag

2025/07

Understanding the Benefits and Functionality of Twin Screw Extrusion Lines

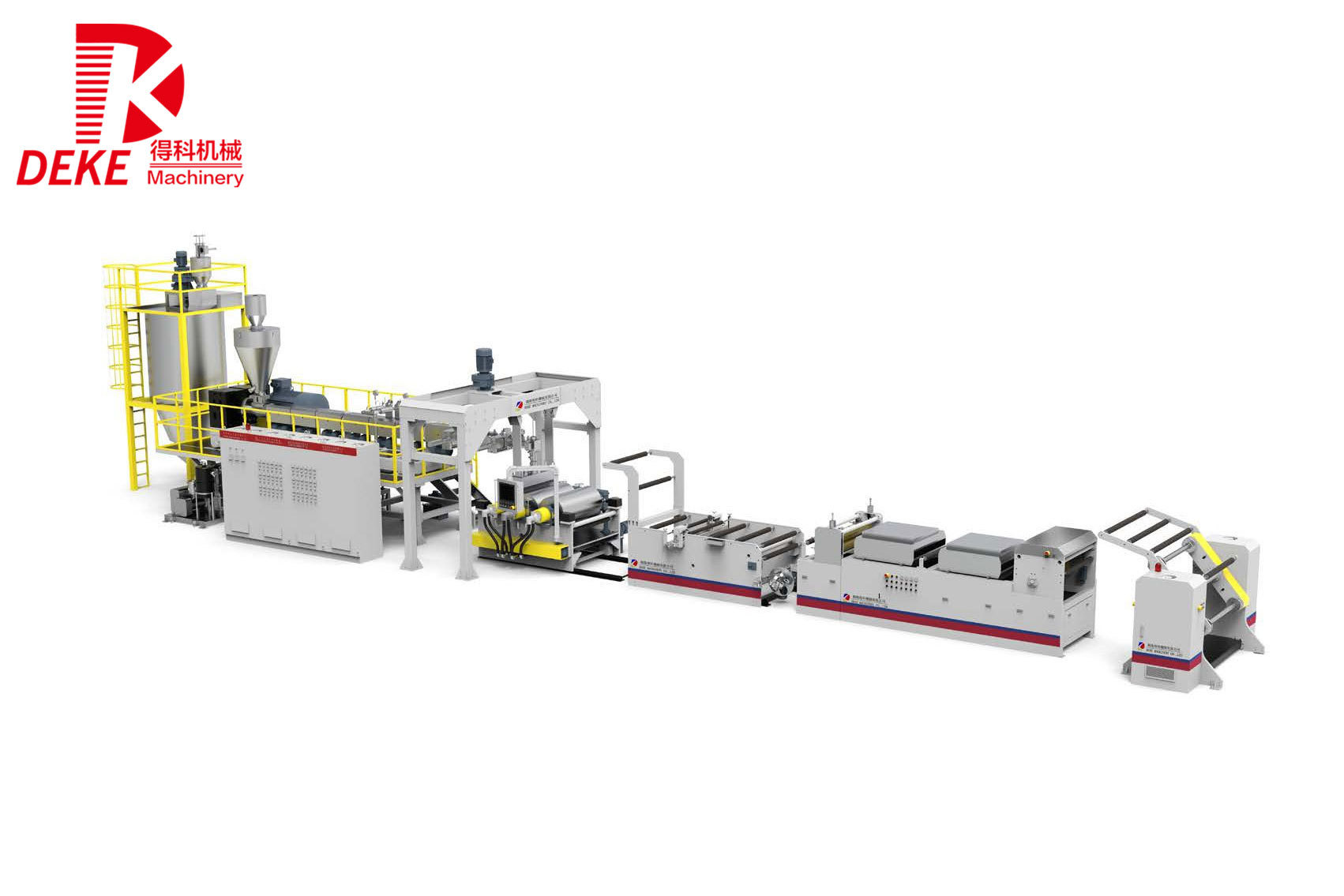

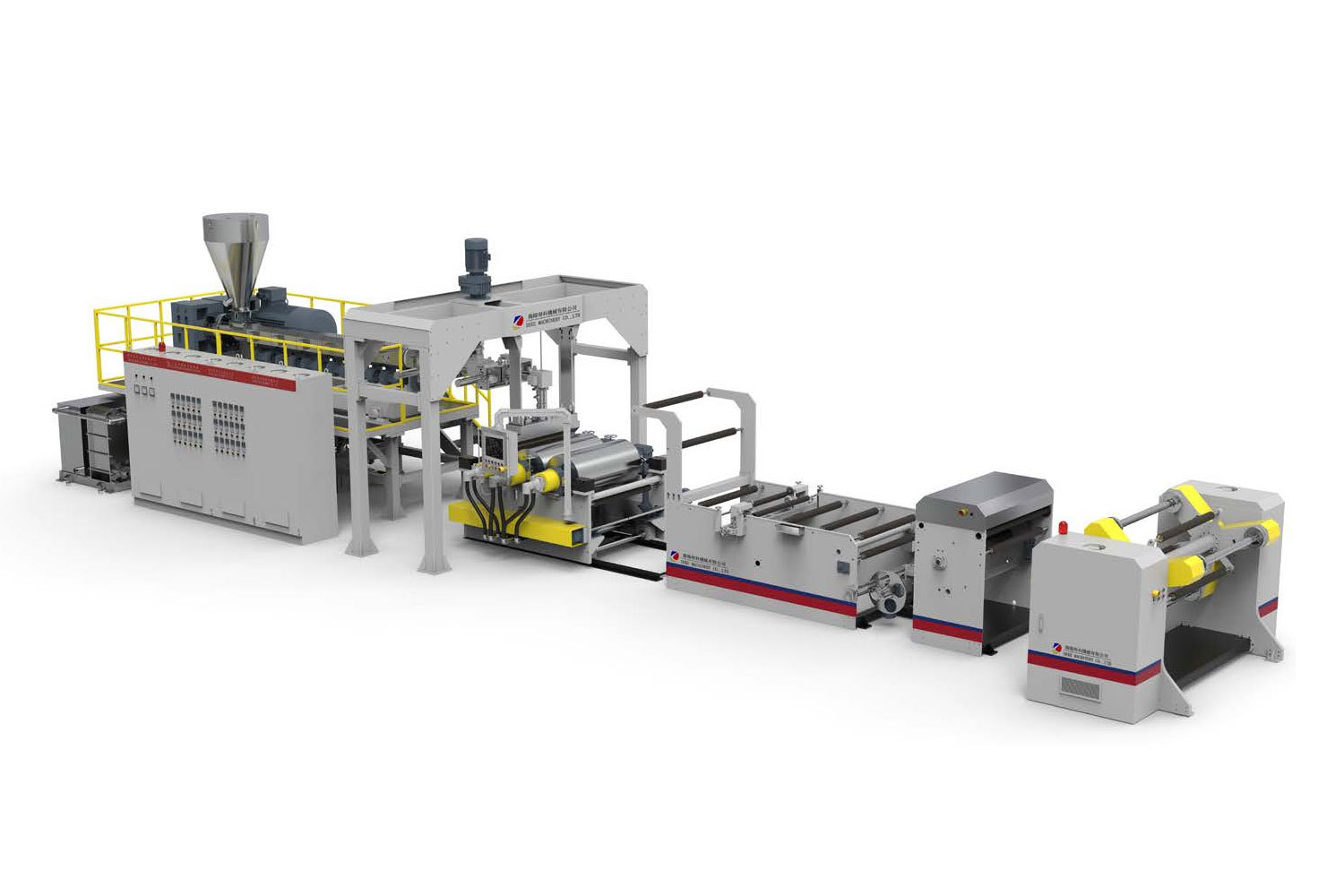

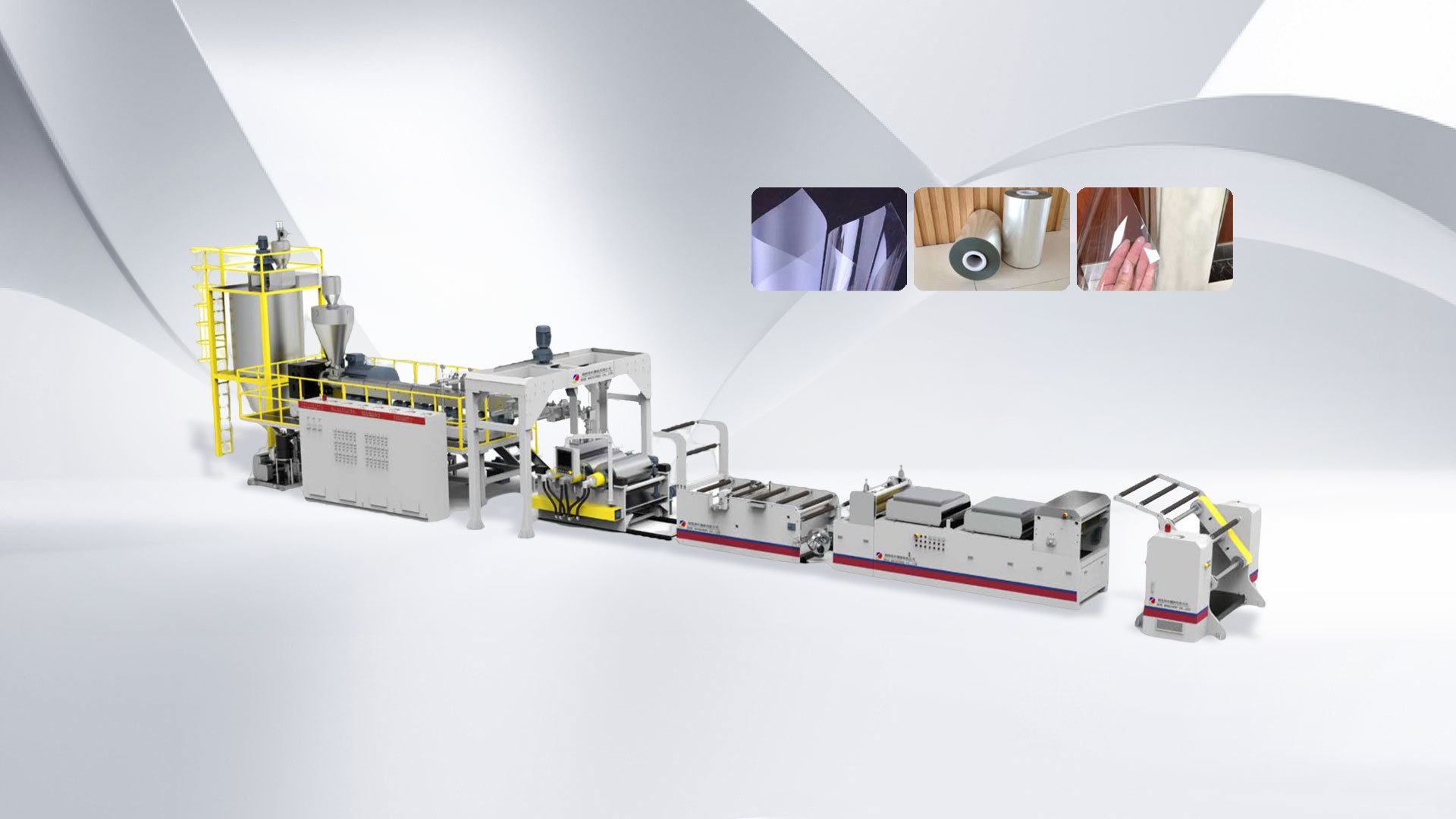

--- Twin screw extrusion lines are a vital component in the realm of plastic processing machinery, specifically designed to enhance the mixing, compounding, and extrusion of various materials. Unlike single screw extruders, twin screw extruders feature two intermeshing screws that rotate within a barrel, facilitating superior blending and material handling. One of the primary advantages of a twin

2025/07

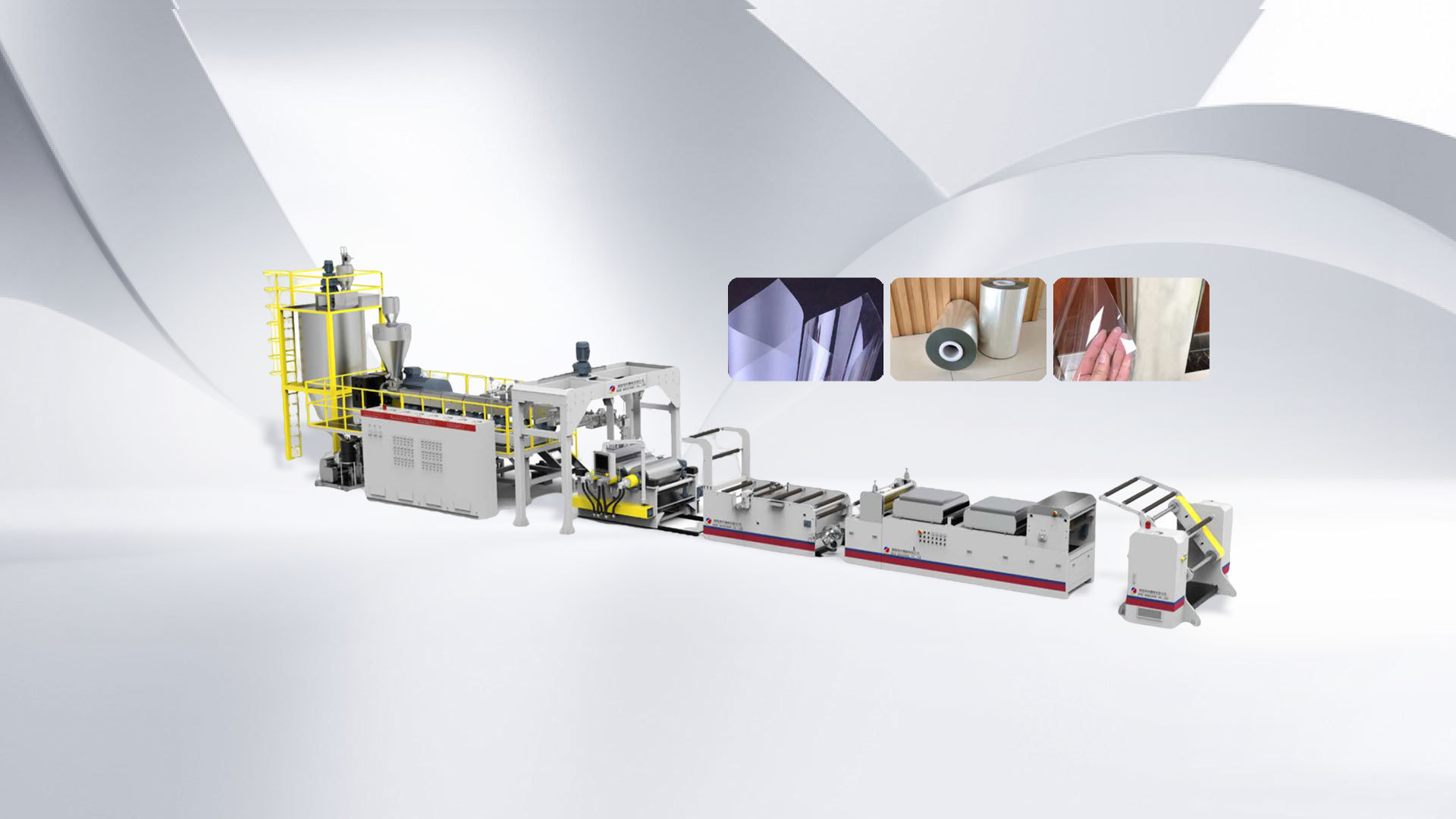

Why Polycarbonate Sheet Extruders Are Essential for Modern Manufacturing

Why Polycarbonate Sheet Extruders Are Essential for Modern Manufacturing Table of Contents 1. Introduction to Polycarbonate Sheet Extruders 2. Importance of Polycarbonate in Manufacturing 3. How Polycarbonate Sheet Extruders Work 4. Advantages of Using Polycarbonate Sheet Extruders 5. Diverse Applications of Polycarbonate Sheets 6. Polycarbonate vs. Other Plastic Materials 7. Ma

2025/07

Understanding Micro Twin Screw Extruders: Key Insights for the Plastics Manufacturing Industry

Micro twin screw extruders are specialized machines designed for the efficient processing of plastics and other materials. These devices are characterized by their double screw configuration, which enhances mixing, kneading, and compounding capabilities. As the demand for precision and versatility in the plastics industry continues to rise, micro twin screw extruders have become increasingly popul

2025/07

Exploring the Global Market for Small Twin Screw Extruders: Trends, Innovations, and Opportunities

Exploring the Global Market for Small Twin Screw Extruders Table of Contents 1. Introduction to Small Twin Screw Extruders 2. Market Overview and Dynamics 1. Market Size and Growth Projections 2. Key Market Drivers 3. Challenges Facing the Market 3. Technological Innovations in Small Twin Screw Extruders 4. Applications of Small Twin Screw Extruders 1. Plastics Proces

2025/07

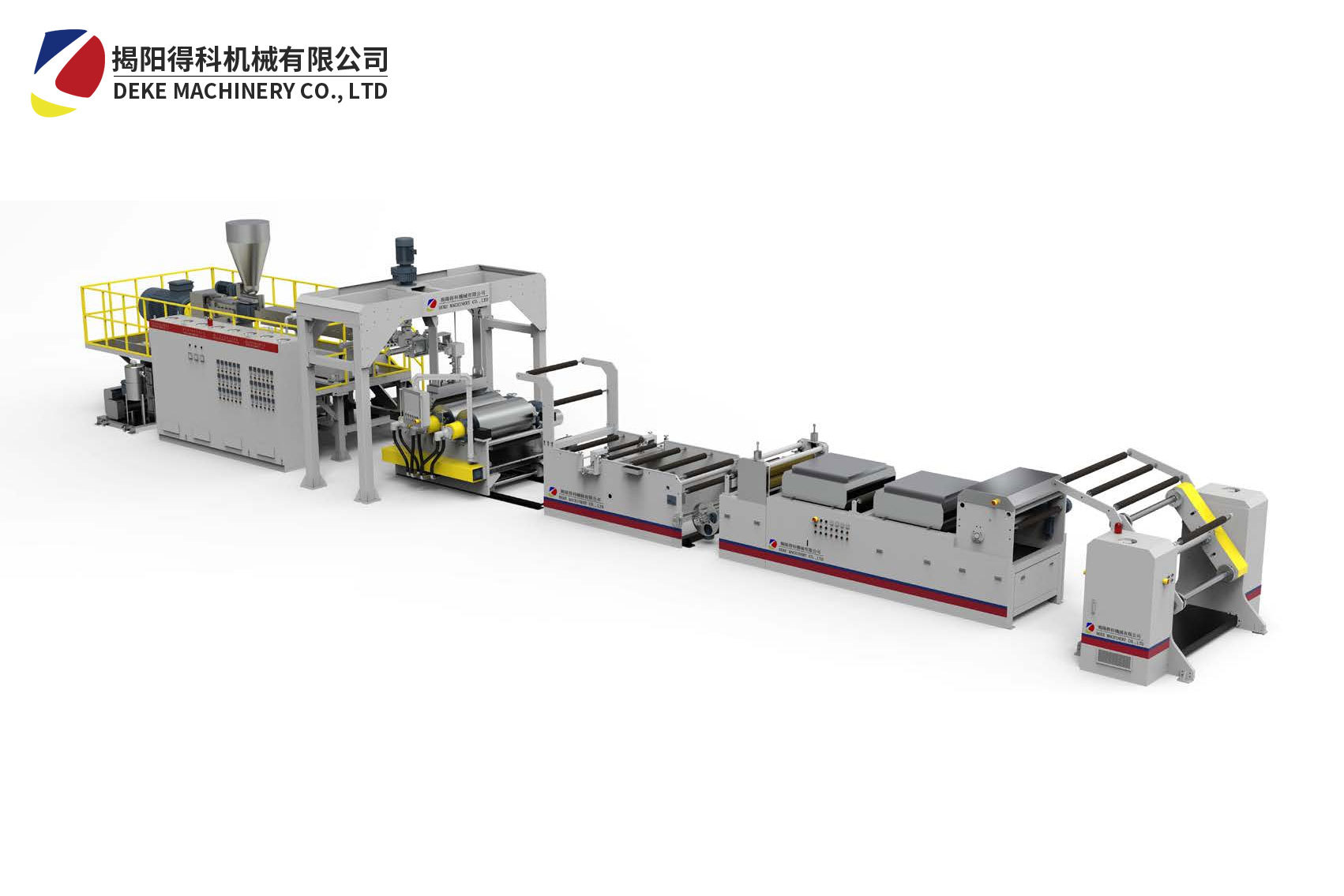

Understanding PET Sheet Extruder Machines: A Comprehensive Guide

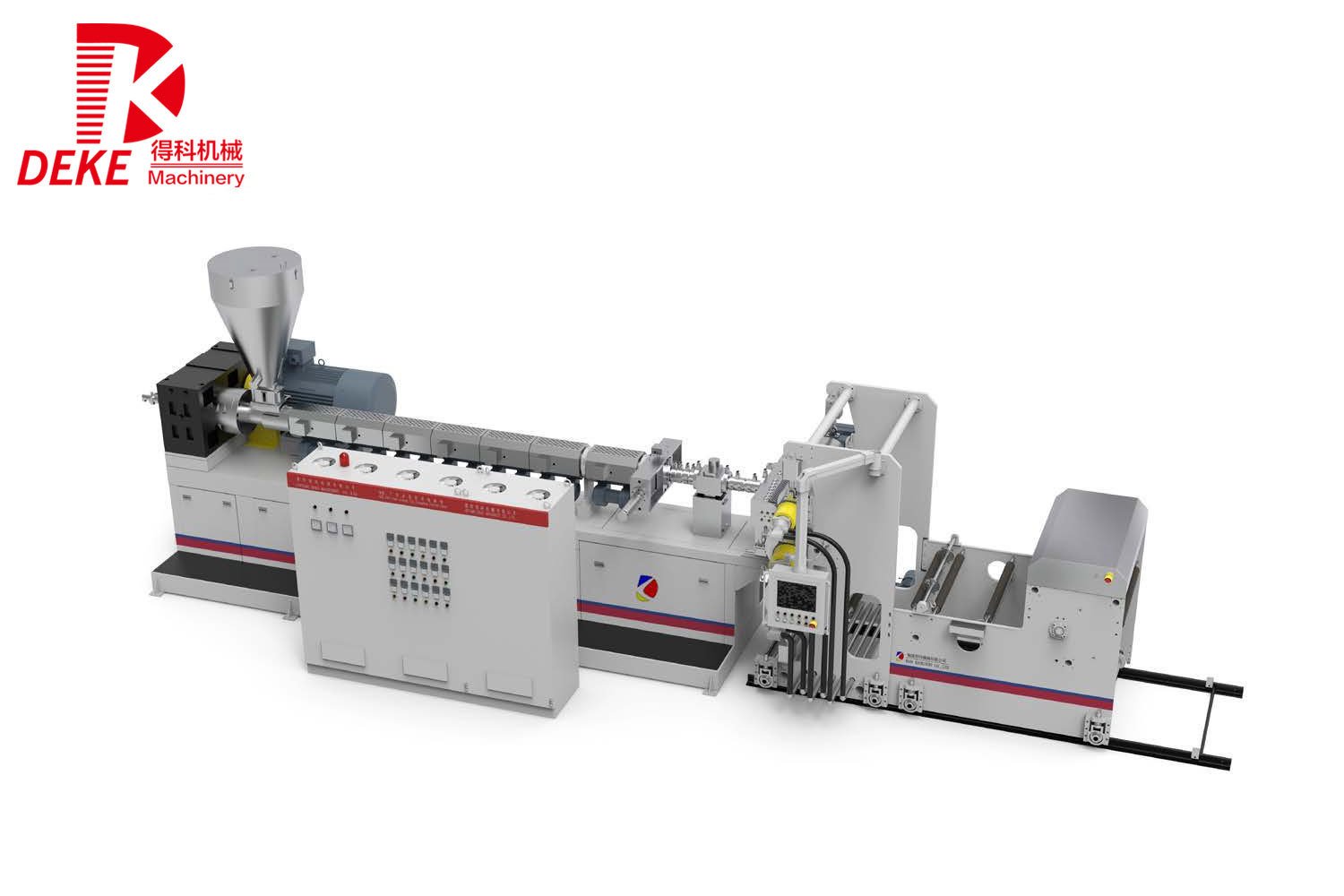

PET sheet extruder machines are specialized equipment used in the plastic processing industry to produce sheets made from polyethylene terephthalate (PET). These machines play a crucial role in various applications, including packaging, automotive parts, and consumer goods. Understanding how these machines work, their components, and their applications can help manufacturers improve efficiency and

2025/07

Exploring the Efficiency of PET Single Screw Extruders in Manufacturing

Exploring the Efficiency of PET Single Screw Extruders in Manufacturing Table of Contents 1. Introduction to PET Single Screw Extruders 2. The Importance of PET in the Manufacturing Process 3. Design and Mechanism of Single Screw Extruders 4. Efficiency Factors of PET Single Screw Extruders 5. Applications of PET Single Screw Extruders in Manufacturing 6. Maintenance and O

2025/07

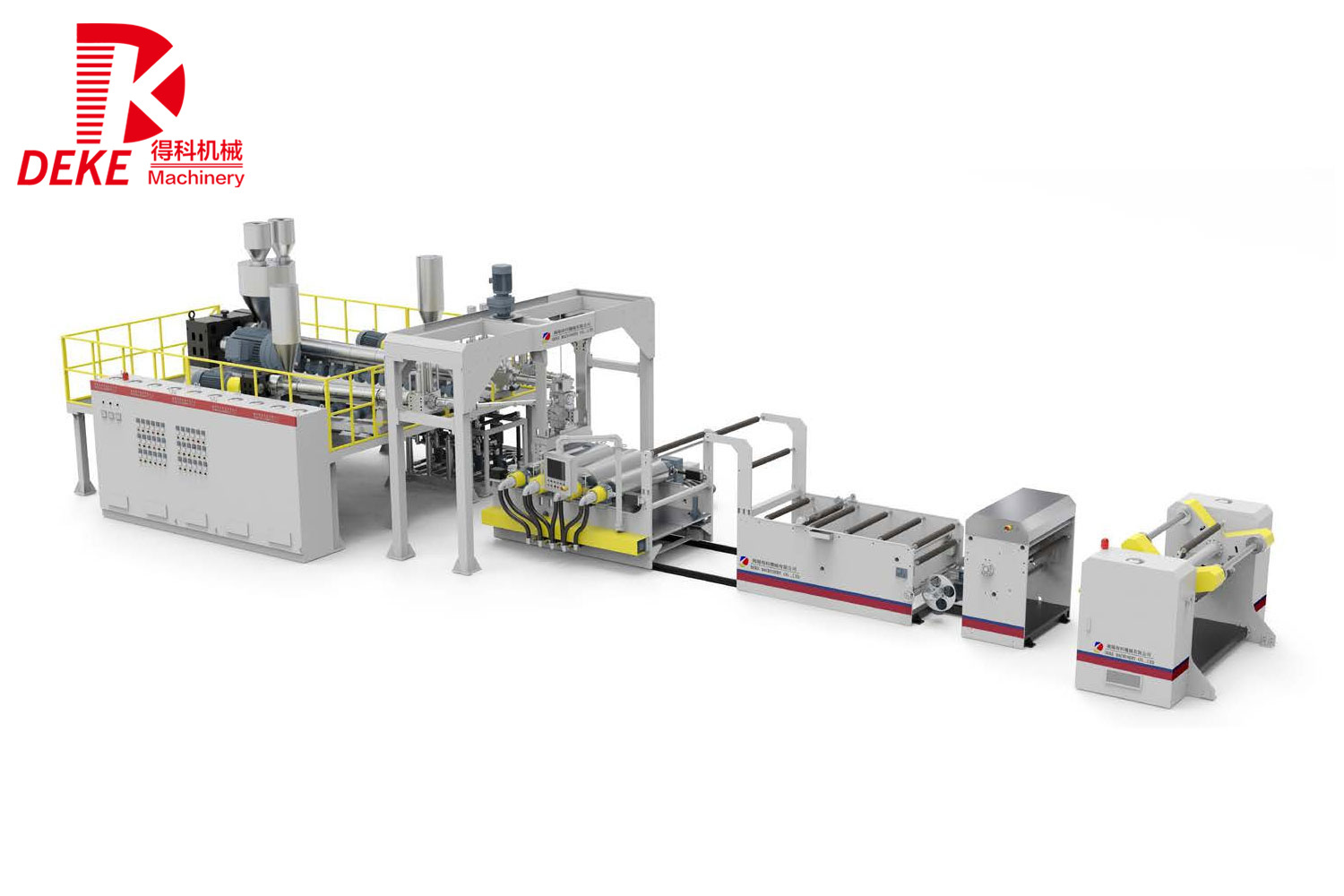

Understanding the Process and Benefits of PP HIPS Sheet Extrusion

PP HIPS (Polypropylene High Impact Polystyrene) sheet extruders are specialized machines designed for the production of high-quality sheets used in a wide range of applications, from packaging to construction. The process involves melting plastic pellets and forcing them through a die to create sheets of desired thickness and width. This technique not only allows for the efficient production of sh

2025/07

Unlocking Efficiency: The Role of Twin Screw Compounders in Modern Plastics Processing

Unlocking Efficiency: The Role of Twin Screw Compounders in Modern Plastics Processing Table of Contents Introduction to Twin Screw Compounders Understanding Plastics Processing What Are Twin Screw Compounders? Advantages of Twin Screw Compounders in Plastics Processing Applications of Twin Screw Compounders Operating Principles of Twin Screw Compounders Maintenance and Support for

2025/07

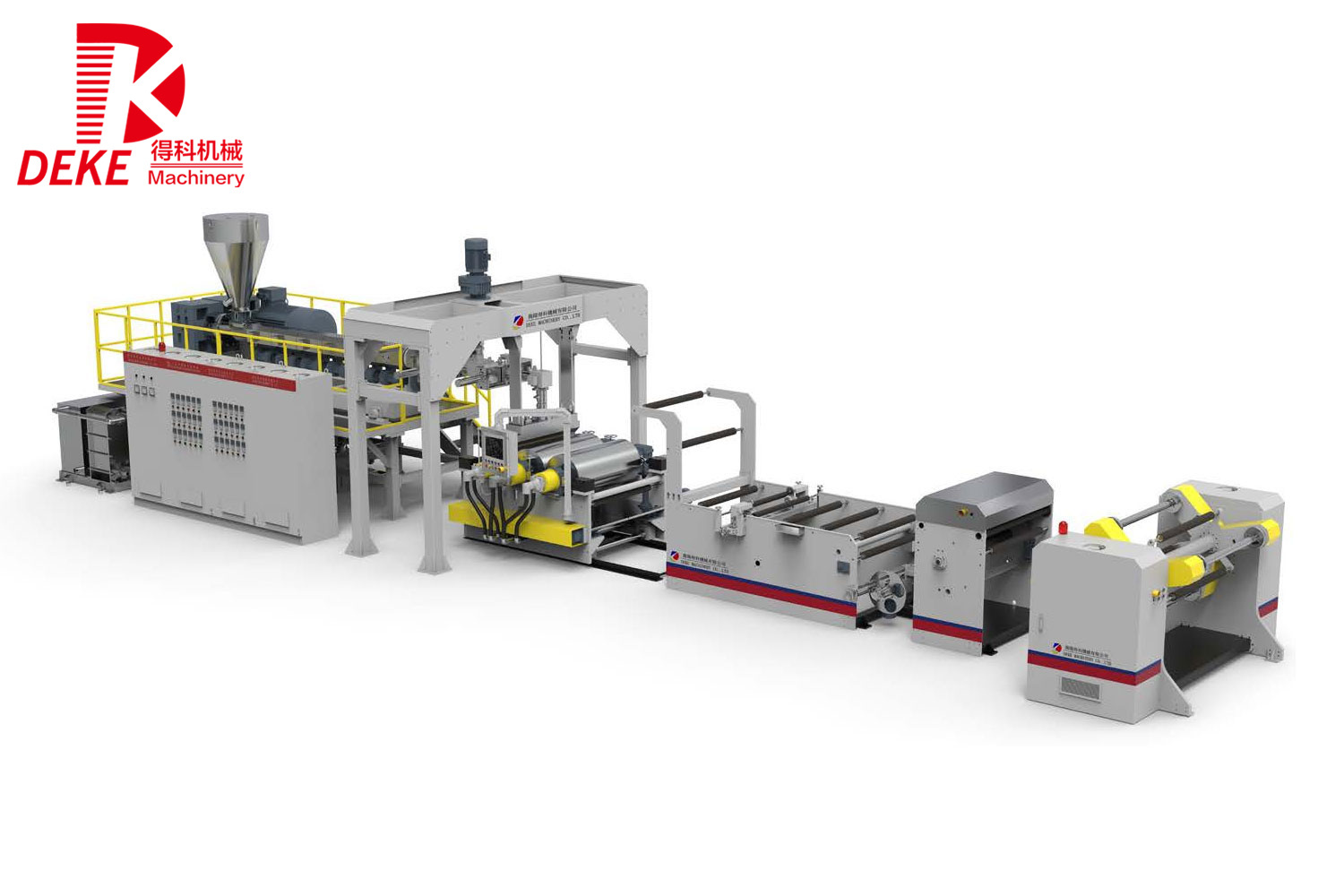

Unlocking the Power of Twin Screw Extrusion Lines in Plastic Processing

In the realm of plastic processing machinery, the twin screw extrusion line stands out as a sophisticated and versatile tool transforming raw materials into finished products. This system features two intermeshing screws that rotate simultaneously within a heated barrel, allowing for efficient melting, mixing, and extruding of plastic materials. The design and functionality of twin screw extrusion

RELATED INFORMATION

Why Choosing a Twin Screw Compounder Can Transform Your Plastic Manufacturing

Why Choosing a Twin Screw Compounder Can Transform Your Plastic Manufacturing Manufacturing in the plastic industry involves intricate processes that require precision, efficiency, and innovation. Among the various technologies available, the twin screw compounder stands out as a transformative solution that can redefine how plastic products are made. This article delves into the numerous advantag

Understanding the Benefits and Functionality of Twin Screw Extrusion Lines

--- Twin screw extrusion lines are a vital component in the realm of plastic processing machinery, specifically designed to enhance the mixing, compounding, and extrusion of various materials. Unlike single screw extruders, twin screw extruders feature two intermeshing screws that rotate within a barrel, facilitating superior blending and material handling. One of the primary advantages of a twin