Understanding PET Sheet Extruder Machines: A Comprehensive Guide

2025-07

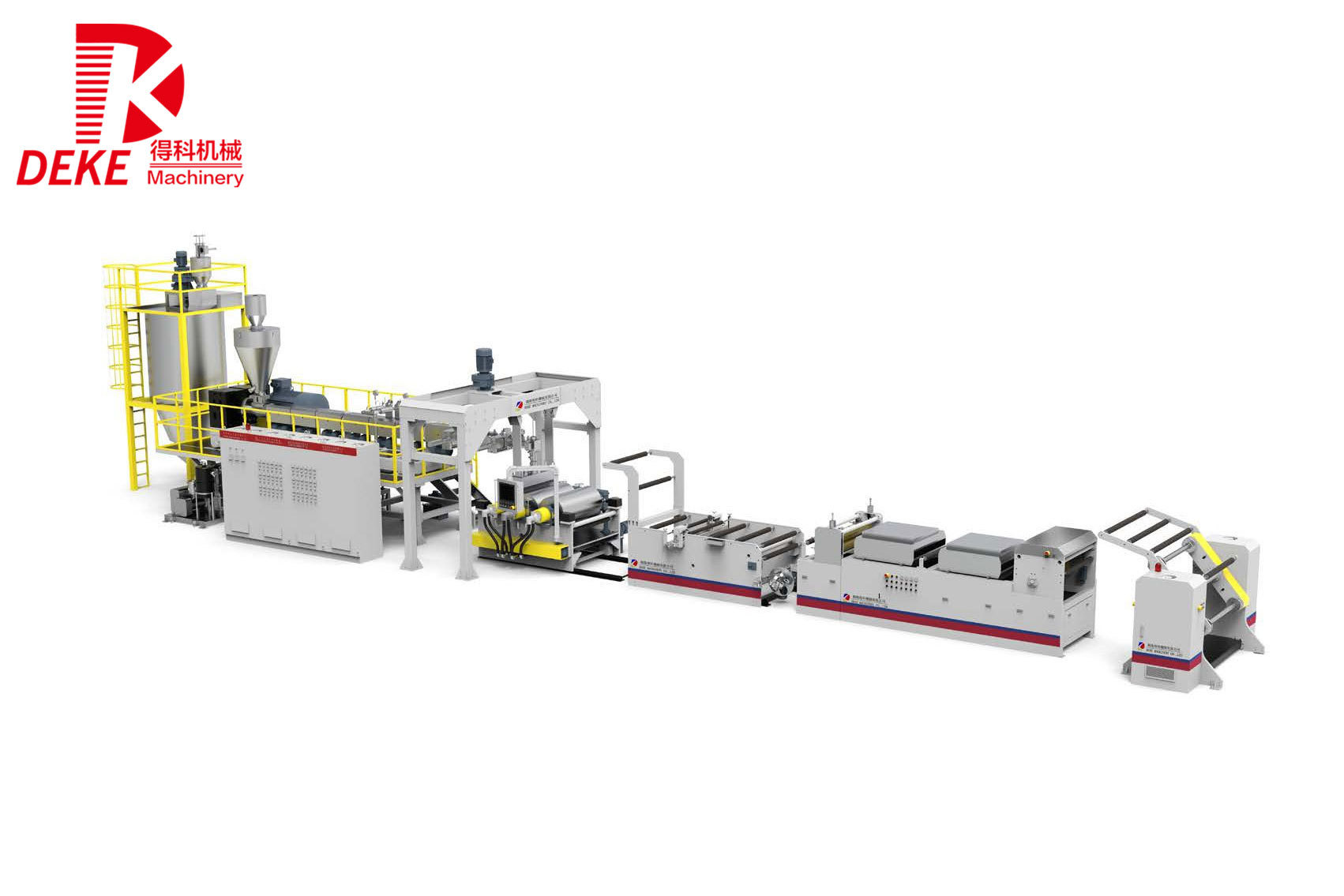

The primary function of a PET sheet extruder machine is to melt PET pellets and extrude the molten material through a die to form sheets. The process begins with feeding PET pellets into a hopper, where they are conveyed to the extruder's barrel. In the barrel, the pellets are subjected to heat and pressure, causing them to melt and flow. Once the material reaches a homogeneous state, it is forced through a die, which shapes it into a flat sheet.

Key components of a PET sheet extruder machine include the extruder screw, barrel, die, and cooling system. The extruder screw is responsible for conveying and mixing the PET material, while the barrel provides the heat necessary for melting. The die shapes the molten PET into a continuous sheet, and the cooling system helps solidify the sheet as it exits the die. Additionally, many machines are equipped with automation features that enhance precision and control during the extrusion process.

The applications of PET sheets produced by extruder machines are vast. In the packaging industry, PET sheets are commonly used for food containers, blister packaging, and thermoformed products due to their excellent clarity, strength, and barrier properties. In the automotive sector, PET sheets are utilized for interior components, providing durability and aesthetic appeal. Furthermore, consumer goods manufacturers often use PET sheets for various products, including signage and displays.

Investing in a high-quality PET sheet extruder machine can significantly benefit manufacturers by increasing production efficiency and reducing waste. Moreover, the versatility of PET sheets allows for customization in thickness, color, and surface finish to meet specific market demands. As sustainability becomes increasingly important, PET's recyclability makes it an attractive option for eco-conscious manufacturers looking to minimize their environmental impact.

In conclusion, PET sheet extruder machines are essential tools in the plastic processing industry, offering a range of applications and benefits. By understanding the intricacies of these machines and their output, manufacturers can optimize their production processes and meet the growing demands of various markets. Investing in advanced technology and staying informed about industry trends will position businesses for success in an ever-evolving landscape.

Previous Page:

RELATED INFORMATION

Why Choosing a Twin Screw Compounder Can Transform Your Plastic Manufacturing

Why Choosing a Twin Screw Compounder Can Transform Your Plastic Manufacturing Manufacturing in the plastic industry involves intricate processes that require precision, efficiency, and innovation. Among the various technologies available, the twin screw compounder stands out as a transformative solution that can redefine how plastic products are made. This article delves into the numerous advantag

Understanding the Benefits and Functionality of Twin Screw Extrusion Lines

--- Twin screw extrusion lines are a vital component in the realm of plastic processing machinery, specifically designed to enhance the mixing, compounding, and extrusion of various materials. Unlike single screw extruders, twin screw extruders feature two intermeshing screws that rotate within a barrel, facilitating superior blending and material handling. One of the primary advantages of a twin