2025/07

Understanding PET Sheet Extruder Machines: A Comprehensive Guide

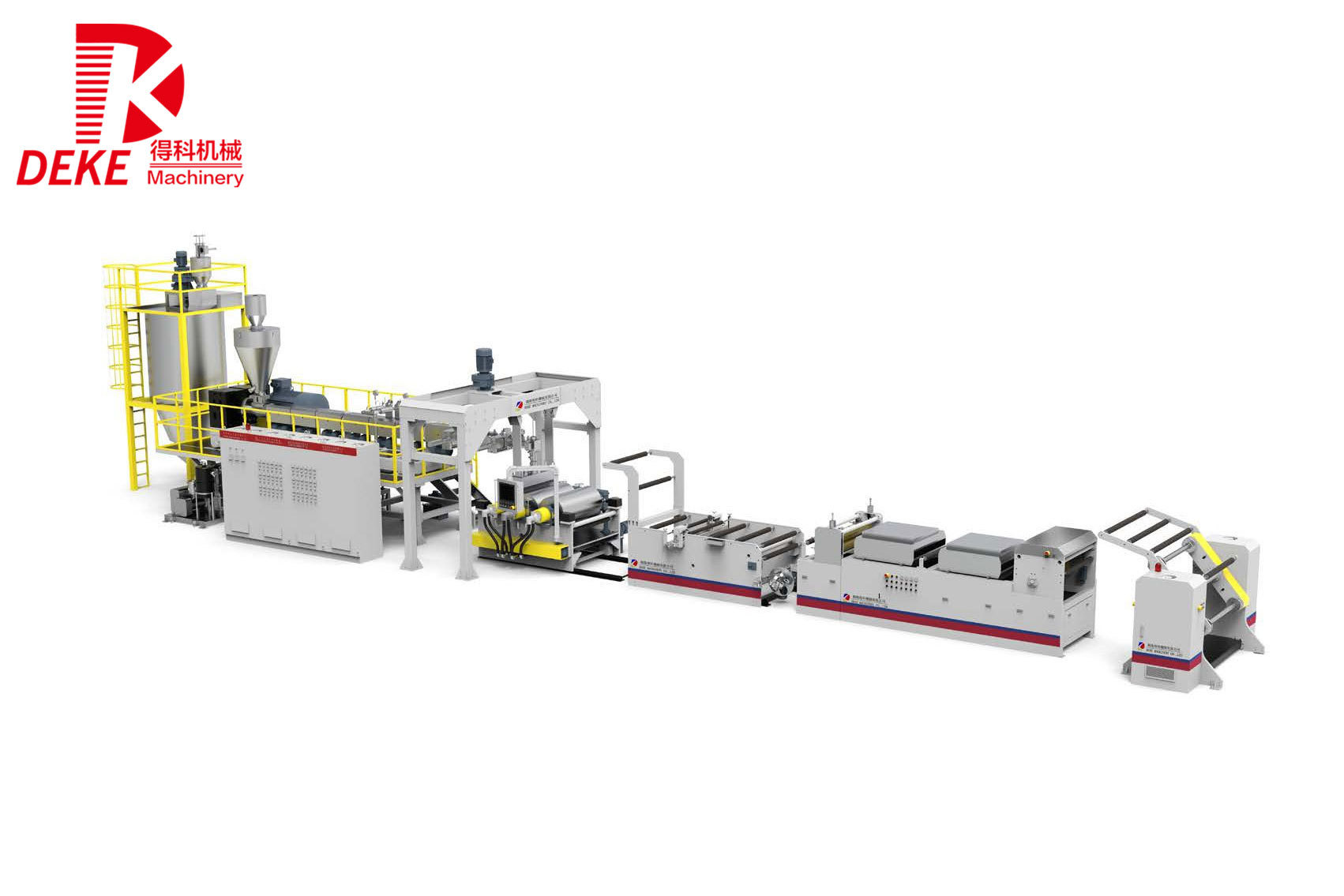

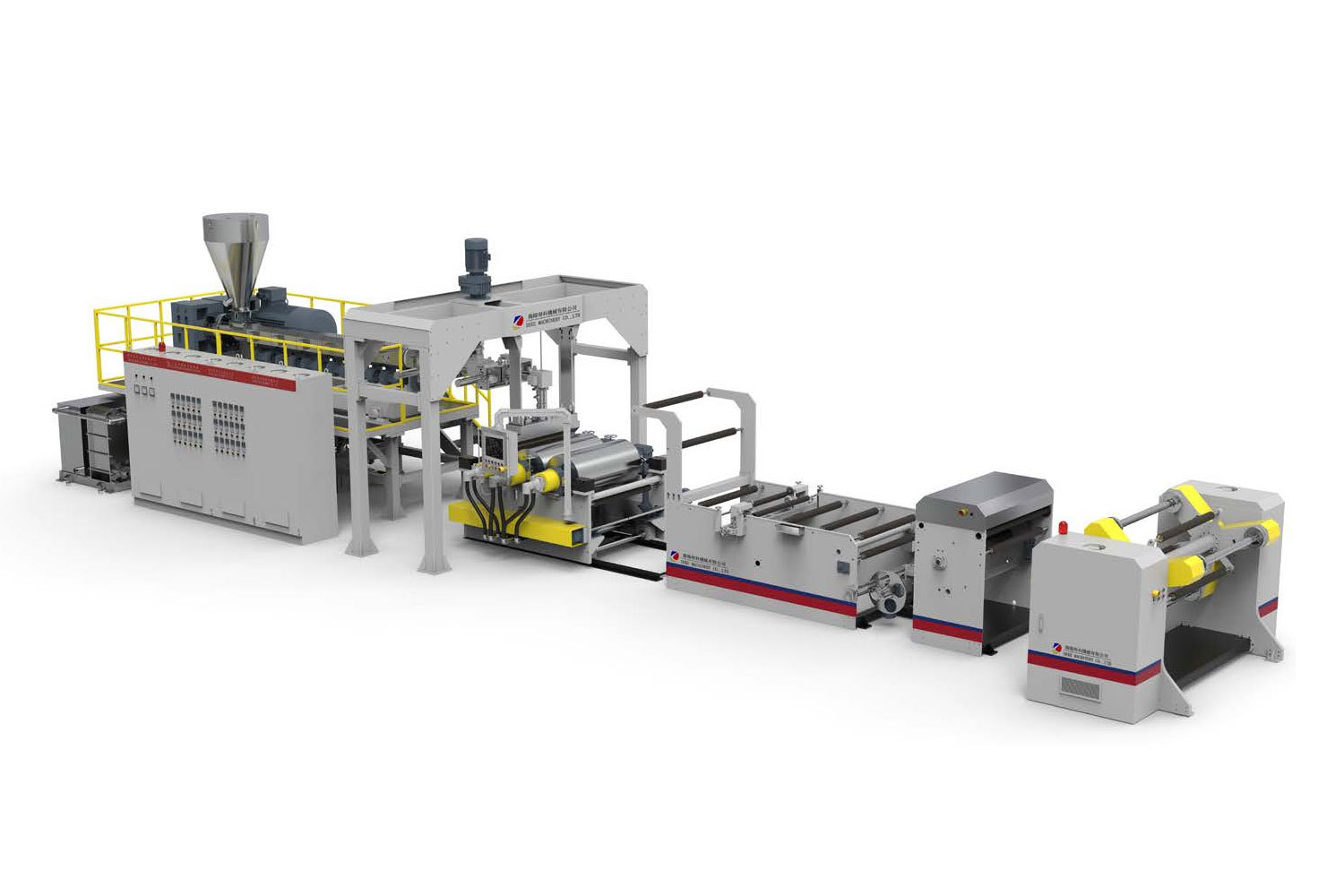

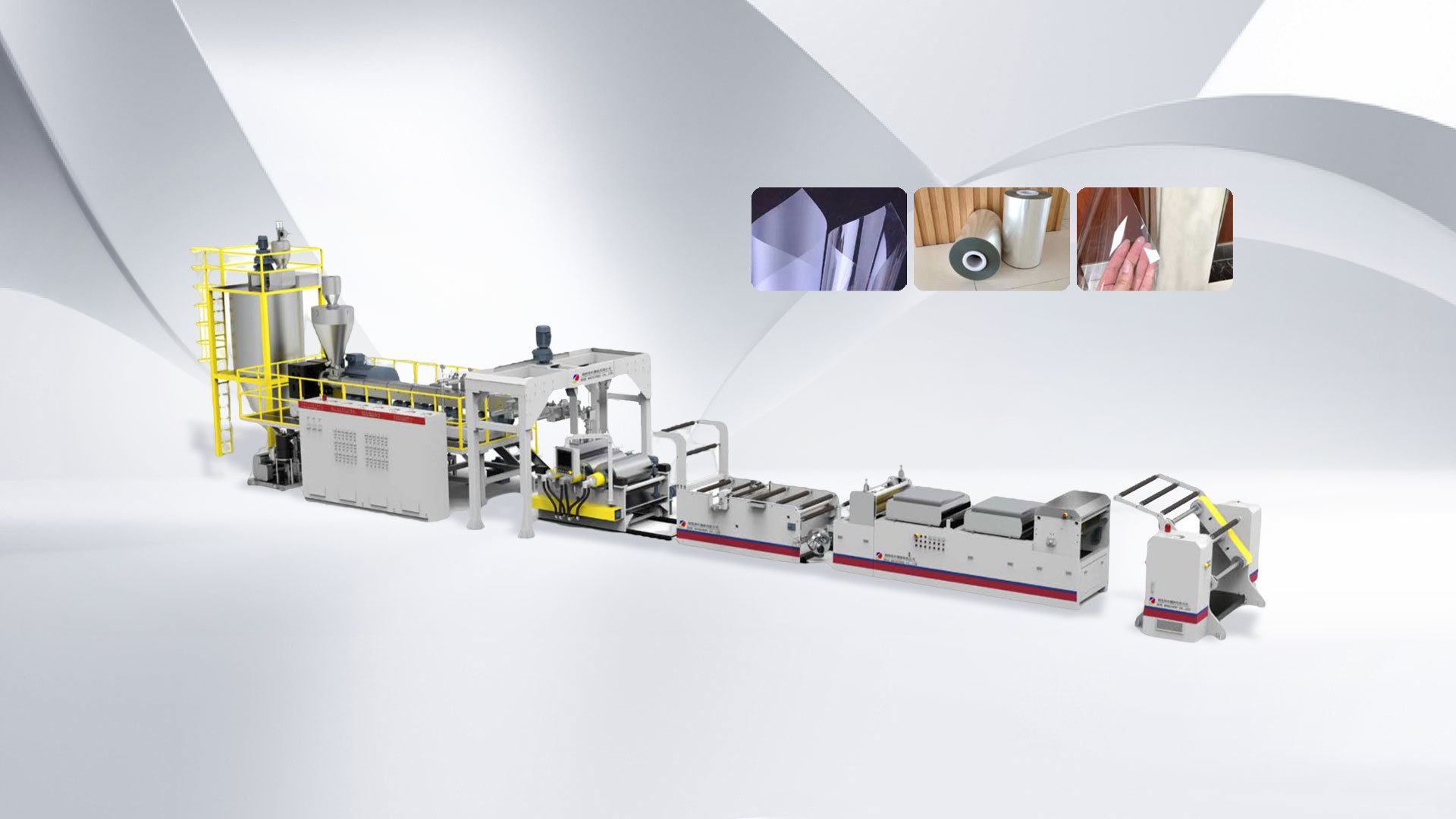

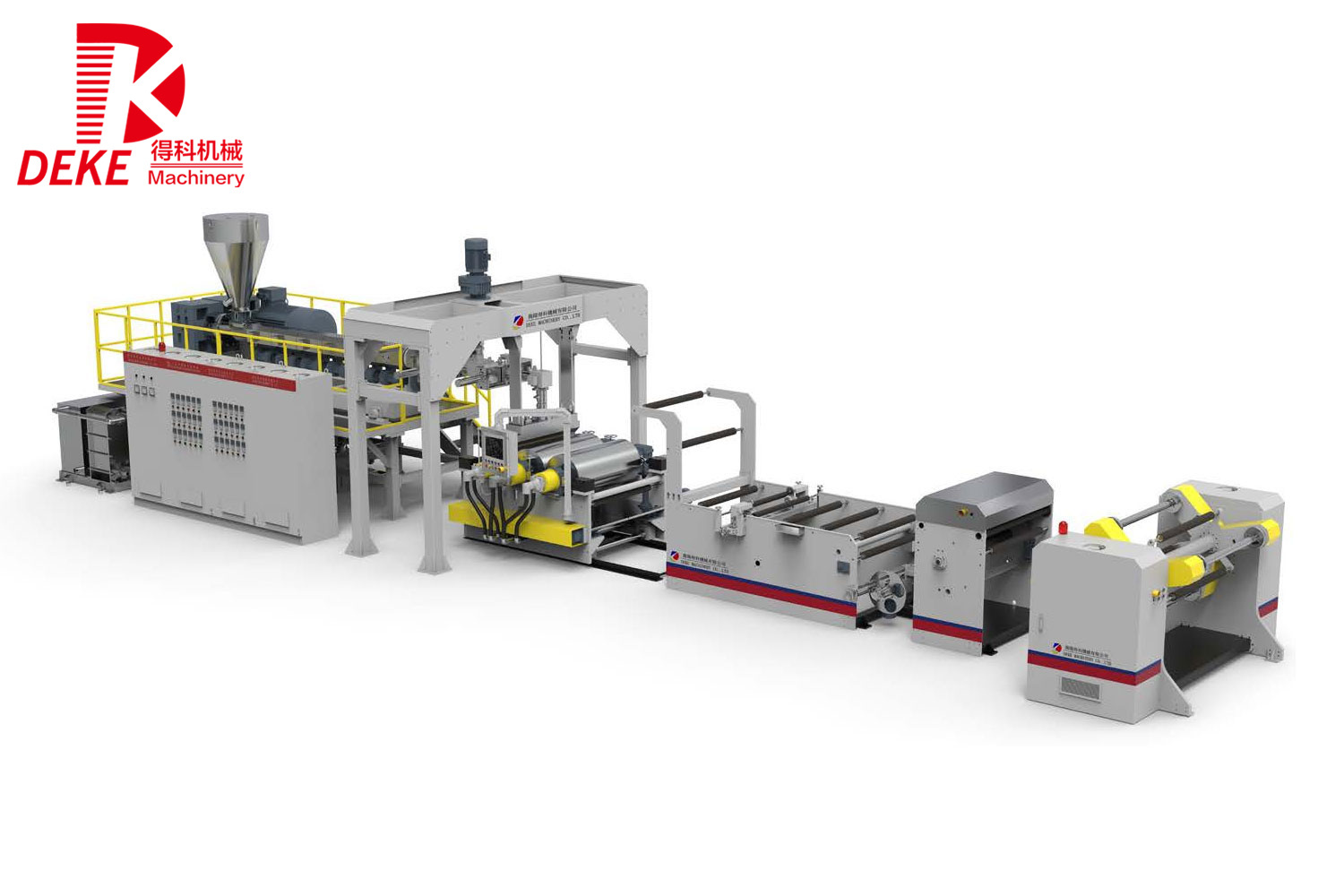

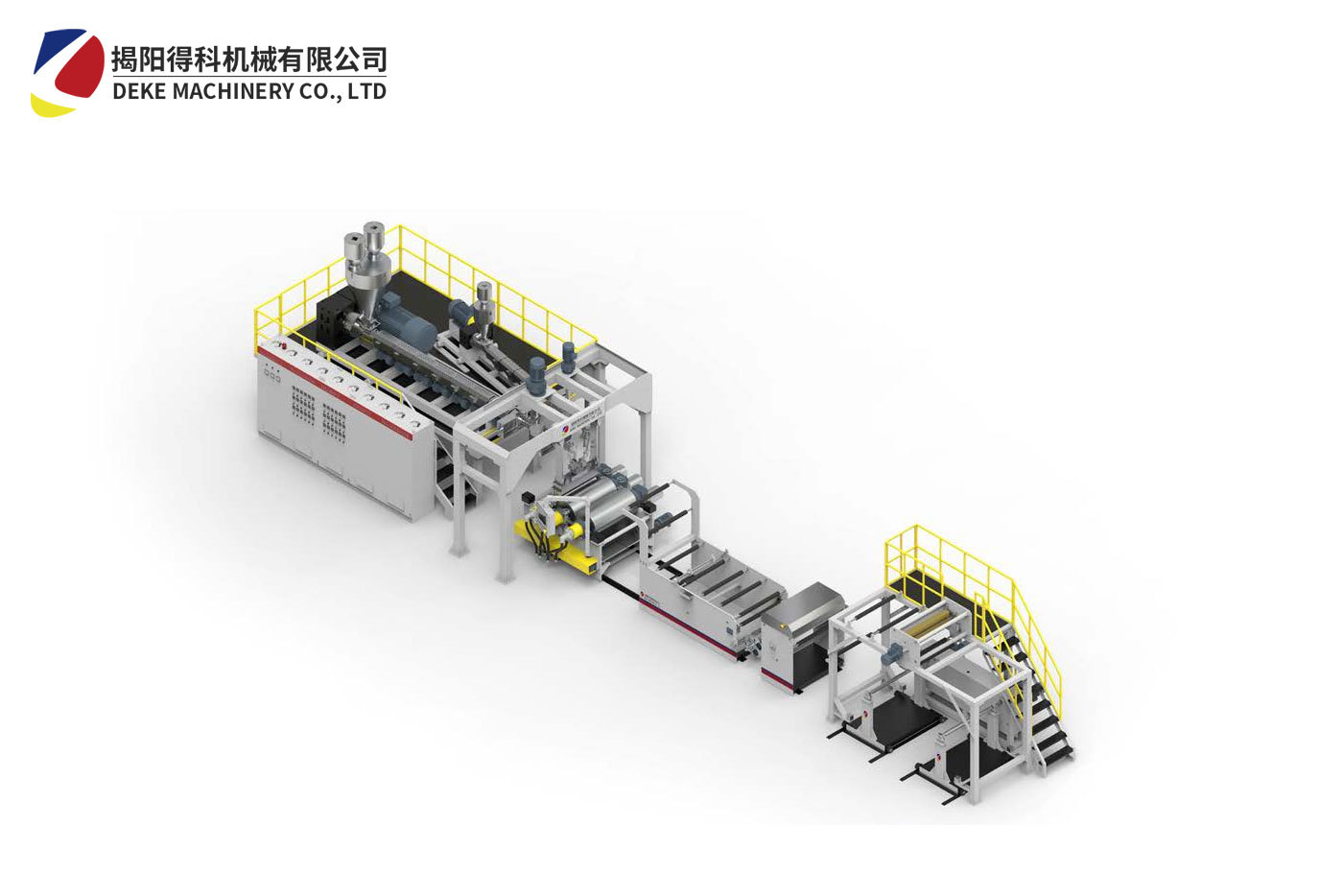

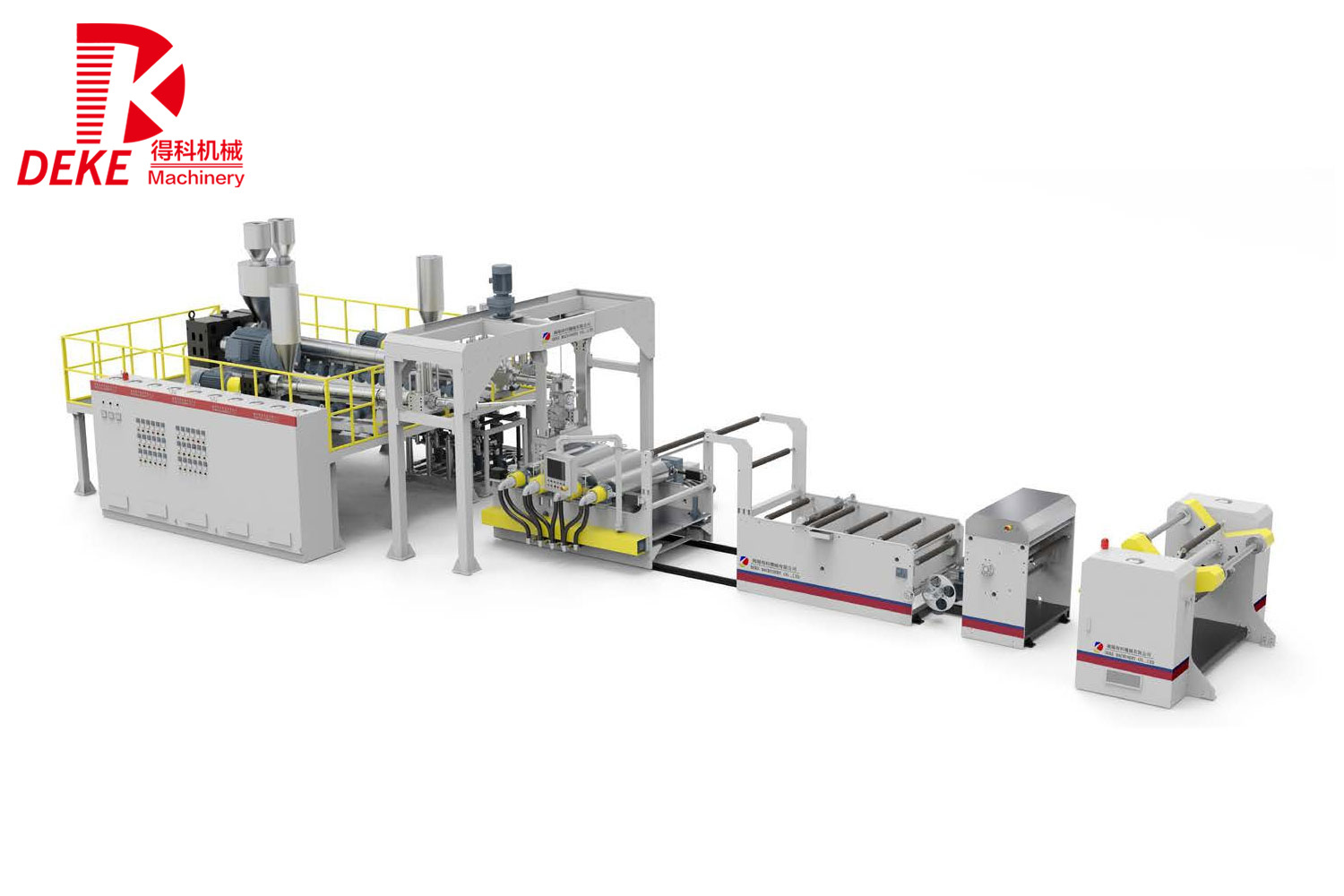

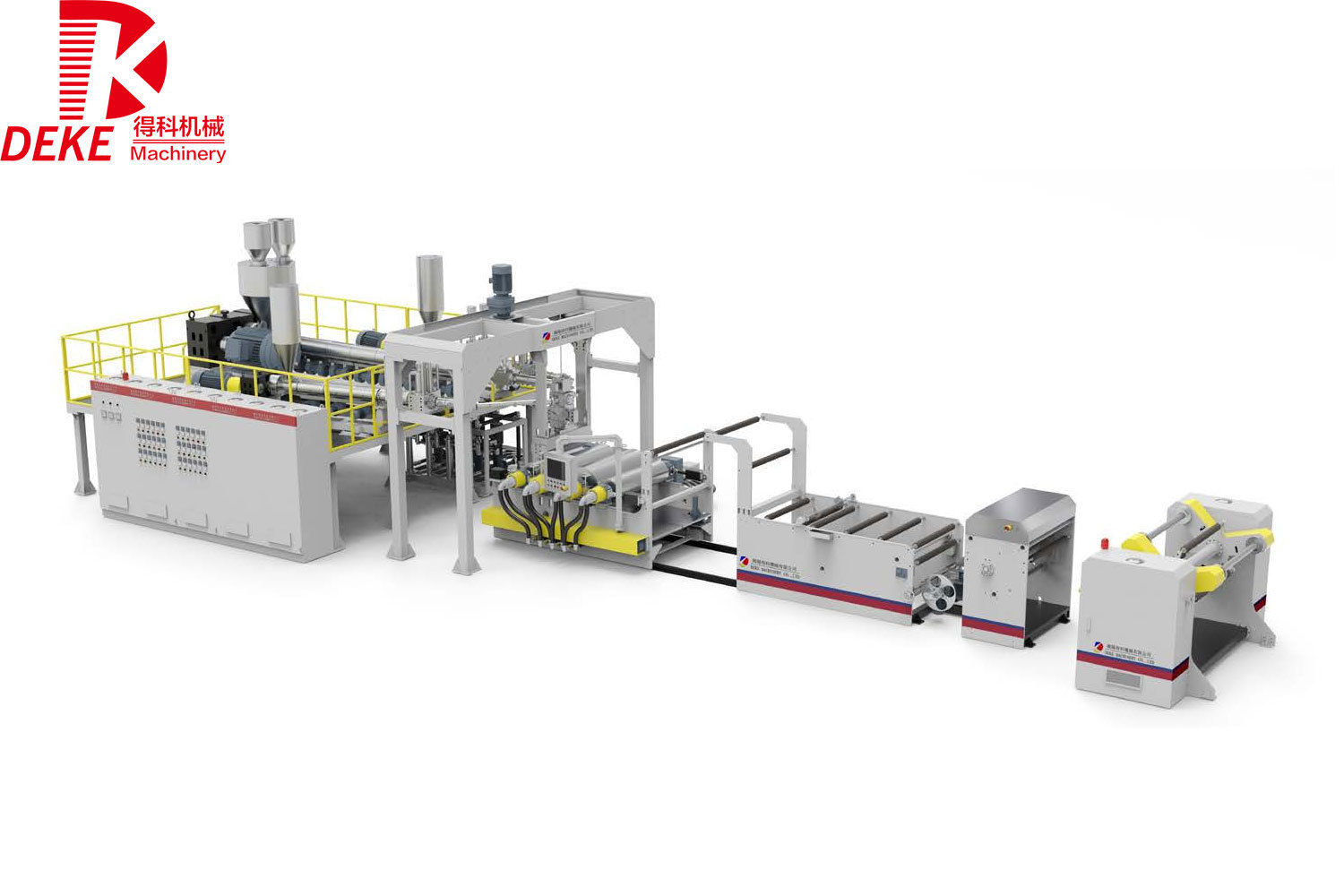

PET sheet extruder machines are specialized equipment used in the plastic processing industry to produce sheets made from polyethylene terephthalate (PET). These machines play a crucial role in various applications, including packaging, automotive parts, and consumer goods. Understanding how these machines work, their components, and their applications can help manufacturers improve efficiency and

2025/07

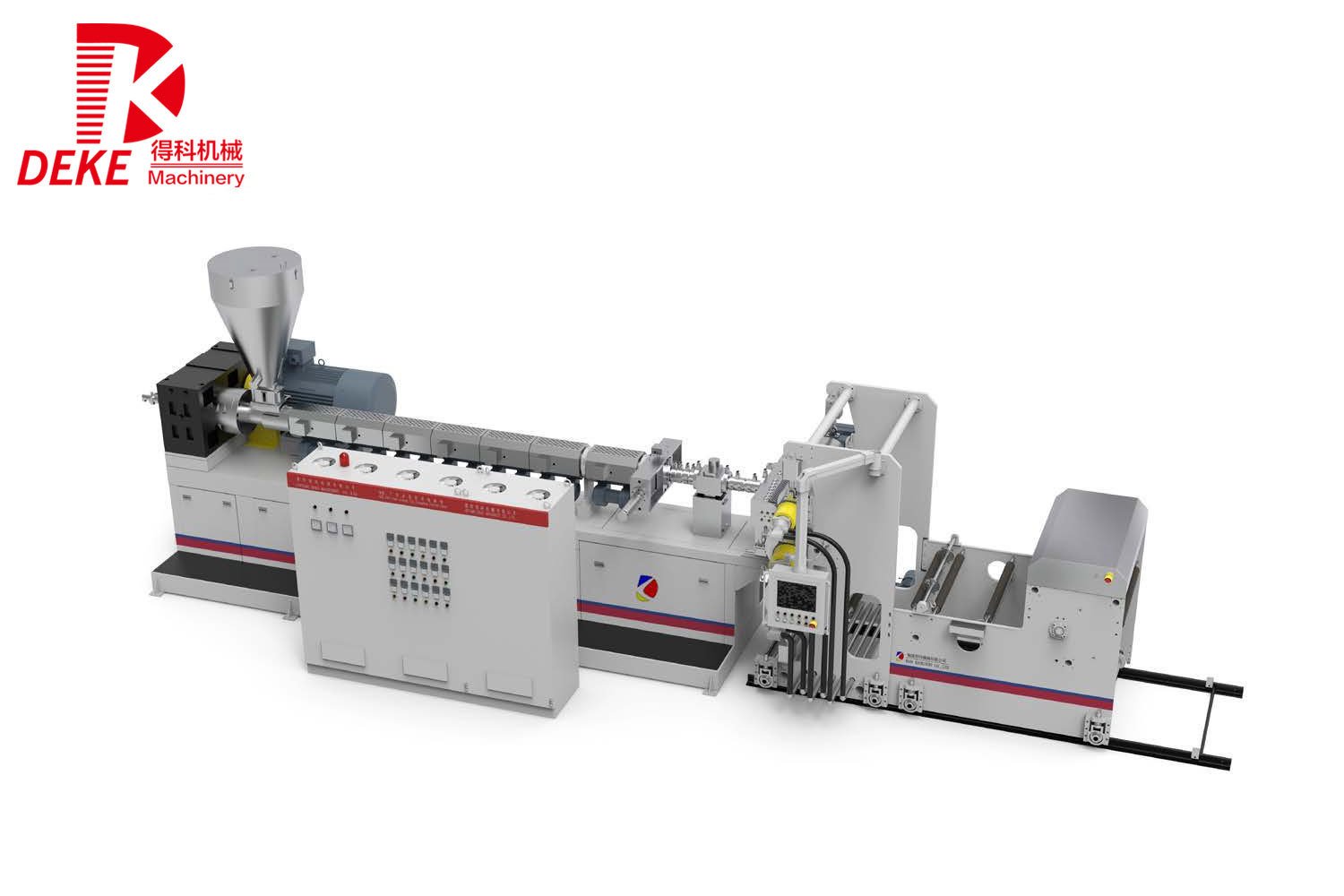

Exploring the Efficiency of PET Single Screw Extruders in Manufacturing

Exploring the Efficiency of PET Single Screw Extruders in Manufacturing Table of Contents 1. Introduction to PET Single Screw Extruders 2. The Importance of PET in the Manufacturing Process 3. Design and Mechanism of Single Screw Extruders 4. Efficiency Factors of PET Single Screw Extruders 5. Applications of PET Single Screw Extruders in Manufacturing 6. Maintenance and O

2025/07

Understanding the Process and Benefits of PP HIPS Sheet Extrusion

PP HIPS (Polypropylene High Impact Polystyrene) sheet extruders are specialized machines designed for the production of high-quality sheets used in a wide range of applications, from packaging to construction. The process involves melting plastic pellets and forcing them through a die to create sheets of desired thickness and width. This technique not only allows for the efficient production of sh

2025/07

Unlocking Efficiency: The Role of Twin Screw Compounders in Modern Plastics Processing

Unlocking Efficiency: The Role of Twin Screw Compounders in Modern Plastics Processing Table of Contents Introduction to Twin Screw Compounders Understanding Plastics Processing What Are Twin Screw Compounders? Advantages of Twin Screw Compounders in Plastics Processing Applications of Twin Screw Compounders Operating Principles of Twin Screw Compounders Maintenance and Support for

2025/07

Unlocking the Power of Twin Screw Extrusion Lines in Plastic Processing

In the realm of plastic processing machinery, the twin screw extrusion line stands out as a sophisticated and versatile tool transforming raw materials into finished products. This system features two intermeshing screws that rotate simultaneously within a heated barrel, allowing for efficient melting, mixing, and extruding of plastic materials. The design and functionality of twin screw extrusion

2025/07

Unlocking the Potential: Top Benefits of Polycarbonate Sheet Extruders

Unlocking the Potential: Top Benefits of Polycarbonate Sheet Extruders Table of Contents 1. Introduction to Polycarbonate Sheet Extruders 2. What Are Polycarbonate Sheets? 3. The Importance of Extrusion in Manufacturing 4. Key Benefits of Polycarbonate Sheet Extruders 4.1 Enhanced Product Quality 4.2 Increased Production Efficiency 4.3 Versatility in Product Design 4.4 Cost-Effectiveness Over Time

2025/07

Maximizing Performance with EVOH High Barrier Sheet Extruders

EVOH (Ethylene Vinyl Alcohol) high barrier sheet extruders are essential in the production of advanced packaging solutions that require superior barrier properties against gases, aromas, and moisture. These extruders are specifically designed to process EVOH materials, which are known for their excellent compatibility with other polymers and outstanding performance in preserving product integrity.

2025/07

What Makes EVOH a Preferred Choice in Extrusion Technology?

What Makes EVOH a Preferred Choice in Extrusion Technology? The world of manufacturing is constantly evolving, and with it, the materials we use to create high-quality products. One such material that has gained significant traction in the extrusion industry is **EVOH (Ethylene Vinyl Alcohol)**. This innovative polymer is celebrated for its exceptional barrier properties, making it a preferred cho

2025/07

Unlocking the Potential of EVOH High Barrier Sheet Extruders in Plastic Processing

EVOH (Ethylene Vinyl Alcohol) high barrier sheet extruders are crucial in various applications, particularly in the packaging sector. These extruders are designed to produce sheets that exhibit excellent barrier properties against gases, moisture, and odors. The unique composition of EVOH provides a combination of flexibility and high-performance barrier characteristics, making it an ideal materia

2025/07

EVOH High Barrier Sheets: Enhancing Product Longevity Through Effective Extrusion

EVOH High Barrier Sheets: Enhancing Product Longevity Through Effective Extrusion Table of Contents 1. Introduction to EVOH High Barrier Sheets 2. What is EVOH? 3. Benefits of EVOH High Barrier Sheets 4. The Extrusion Process Explained 5. Applications of EVOH High Barrier Sheets 6. Sustainability Aspects of EVOH Materials 7. The Future of EVOH Technology 8. Frequen

RELATED INFORMATION

Understanding PET Sheet Extruder Machines: A Comprehensive Guide

PET sheet extruder machines are specialized equipment used in the plastic processing industry to produce sheets made from polyethylene terephthalate (PET). These machines play a crucial role in various applications, including packaging, automotive parts, and consumer goods. Understanding how these machines work, their components, and their applications can help manufacturers improve efficiency and

Exploring the Efficiency of PET Single Screw Extruders in Manufacturing

Exploring the Efficiency of PET Single Screw Extruders in Manufacturing Table of Contents 1. Introduction to PET Single Screw Extruders 2. The Importance of PET in the Manufacturing Process 3. Design and Mechanism of Single Screw Extruders 4. Efficiency Factors of PET Single Screw Extruders 5. Applications of PET Single Screw Extruders in Manufacturing 6. Maintenance and O