Unlocking the Power of Twin Screw Extrusion Lines in Plastic Processing

2025-07

One of the primary advantages of twin screw extrusion lines is their superior mixing capabilities. The intermeshing screws create a highly turbulent environment that promotes thorough homogenization of the material. This is particularly beneficial when working with additives, pigments, or reinforcements, as it ensures a uniform distribution throughout the polymer matrix. As a result, manufacturers can produce products with enhanced properties, such as improved strength, flexibility, or color consistency.

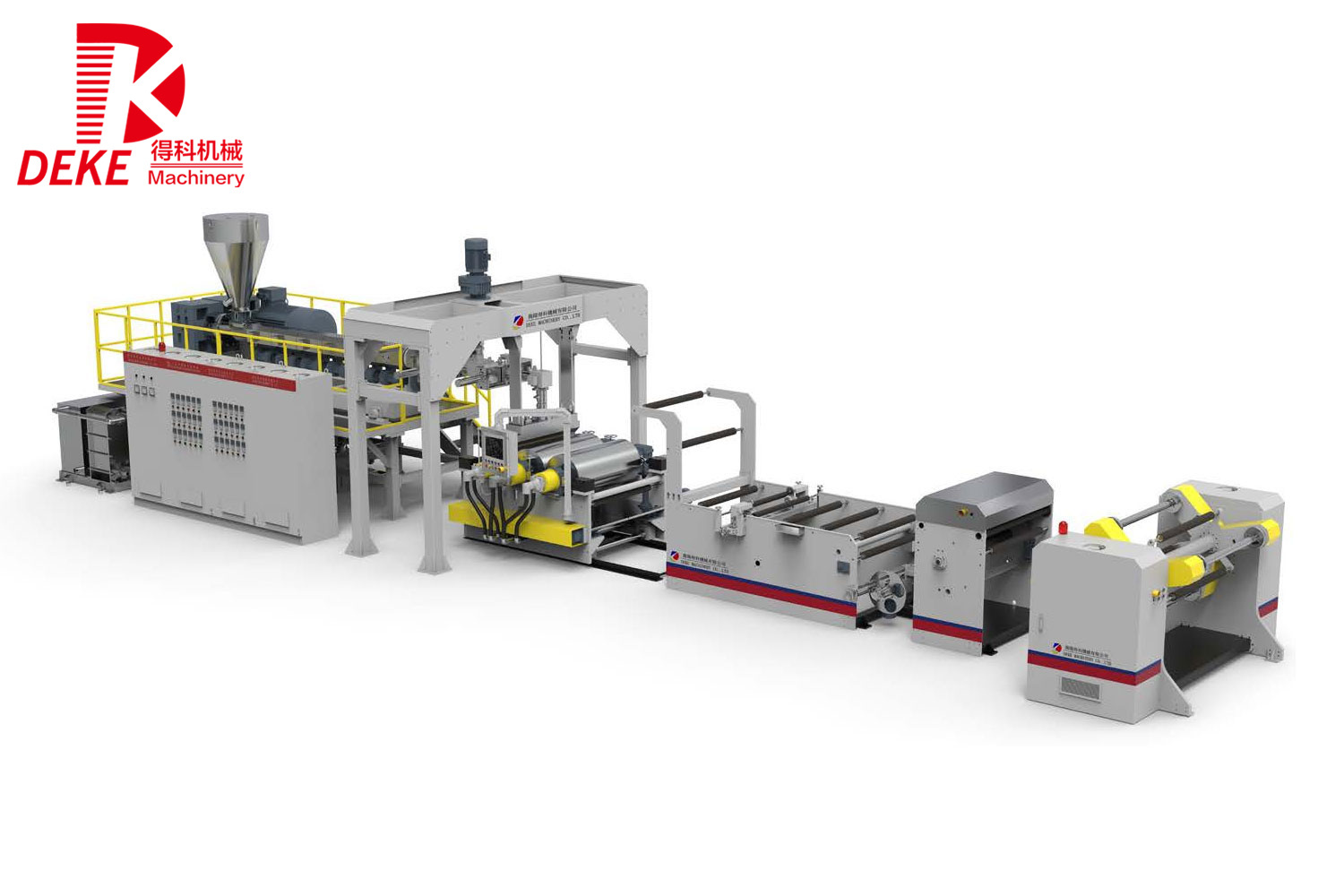

Another key benefit of twin screw extrusion lines is their adaptability to various processing conditions. The screws can be designed with different geometries and configurations, allowing for customization based on specific material requirements. This flexibility enables manufacturers to handle a wide range of thermoplastics, elastomers, and even some thermosetting materials. Additionally, the modular design of twin screw extruders allows for easy integration of downstream equipment, such as pelletizers or cooling systems, further streamlining the production process.

Moreover, twin screw extrusion lines excel in their ability to process materials with varying viscosities. The precise control over temperature and pressure within the extruder enables operators to manage the flow characteristics of different polymers effectively. This capability is crucial for maintaining consistent product quality and optimizing production efficiency. For manufacturers looking to scale up their operations, twin screw extrusion lines can accommodate increased throughput without compromising quality.

In terms of environmental benefits, twin screw extrusion technology has made significant strides. The efficient design minimizes energy consumption during the extrusion process, reducing the overall carbon footprint of manufacturing operations. Additionally, these systems often support the processing of recycled materials, contributing to more sustainable practices within the plastics industry.

Finally, it is essential to acknowledge the importance of proper maintenance and operation of twin screw extrusion lines. Regular checks and upkeep not only extend the lifespan of the equipment but also ensure optimal performance and product quality. Training operators on best practices can further enhance efficiency and reduce downtime.

In summary, twin screw extrusion lines are a cornerstone of plastic processing technology, offering unmatched versatility, efficiency, and product quality. Their advanced mixing capabilities and adaptability to various materials make them an essential choice for manufacturers aiming to stay competitive in the ever-evolving landscape of the plastics industry.

Previous Page:

RELATED INFORMATION

Understanding PET Sheet Extruder Machines: A Comprehensive Guide

PET sheet extruder machines are specialized equipment used in the plastic processing industry to produce sheets made from polyethylene terephthalate (PET). These machines play a crucial role in various applications, including packaging, automotive parts, and consumer goods. Understanding how these machines work, their components, and their applications can help manufacturers improve efficiency and

Exploring the Efficiency of PET Single Screw Extruders in Manufacturing

Exploring the Efficiency of PET Single Screw Extruders in Manufacturing Table of Contents 1. Introduction to PET Single Screw Extruders 2. The Importance of PET in the Manufacturing Process 3. Design and Mechanism of Single Screw Extruders 4. Efficiency Factors of PET Single Screw Extruders 5. Applications of PET Single Screw Extruders in Manufacturing 6. Maintenance and O