2025/06

Understanding PLA Sheet Extrusion Lines: A Comprehensive Guide

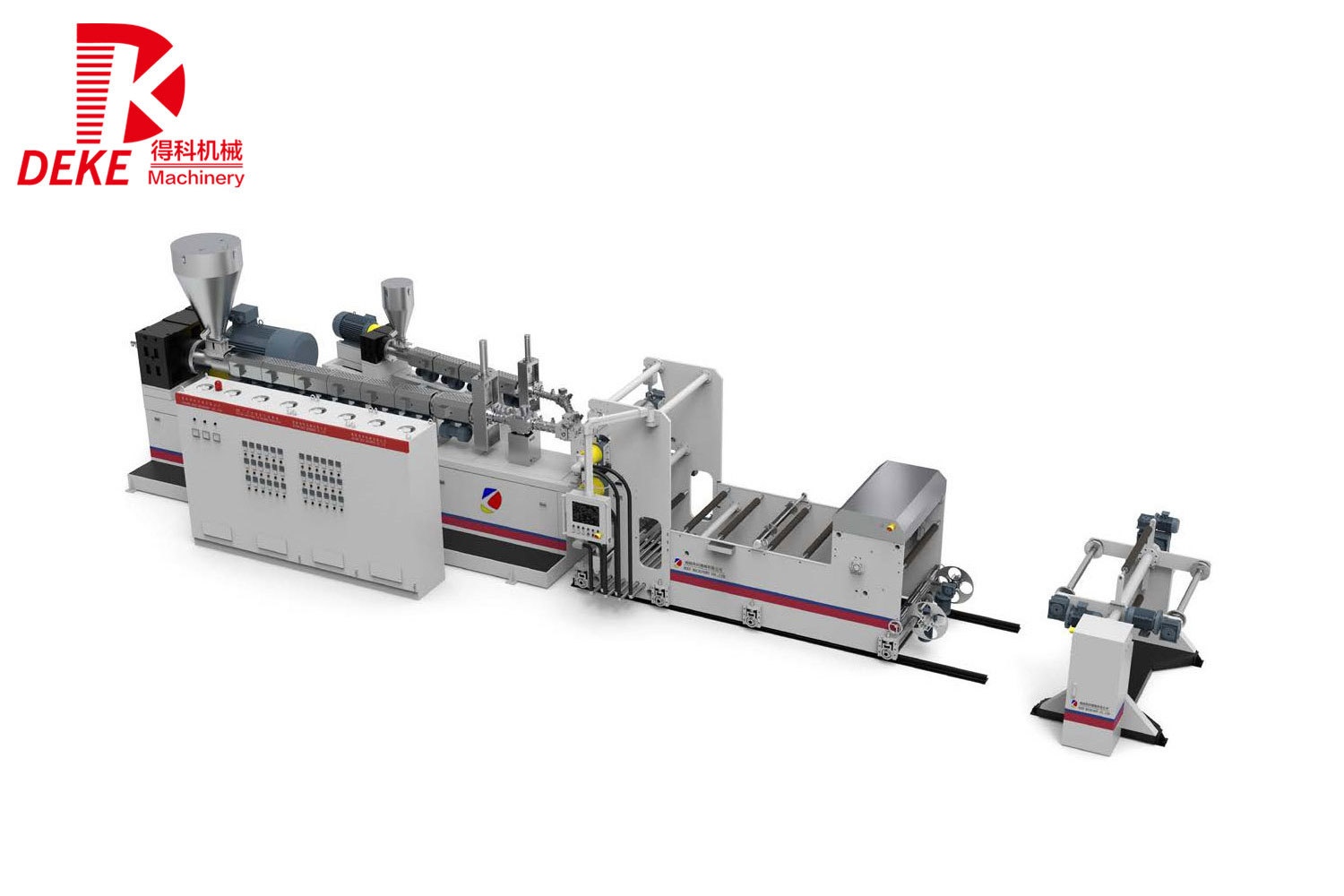

PLA (Polylactic Acid) sheet extrusion lines are specialized equipment used in the manufacturing of sheets made from biodegradable plastics. These lines focus on processing PLA, a renewable resource derived from corn starch or sugarcane, making it an environmentally friendly alternative to traditional petroleum-based plastics. Understanding the mechanics and advantages of PLA sheet extrusion lines

2025/06

Conical screw extruder is a kind of equipment that plays an important role in the fields of plastic processing.

2025/06

How PLA Sheet Extrusion Lines Are Revolutionizing Plastic Processing

How PLA Sheet Extrusion Lines Are Revolutionizing Plastic Processing Introduction to PLA and Its Significance in Plastic Processing Polylactic Acid (PLA) has emerged as a **game-changer** in the world of plastics, primarily owing to its biodegradable characteristics and renewable sourcing. As environmental concerns intensify, the demand for sustainable materials like PLA has skyrocketed. This arti

2025/06

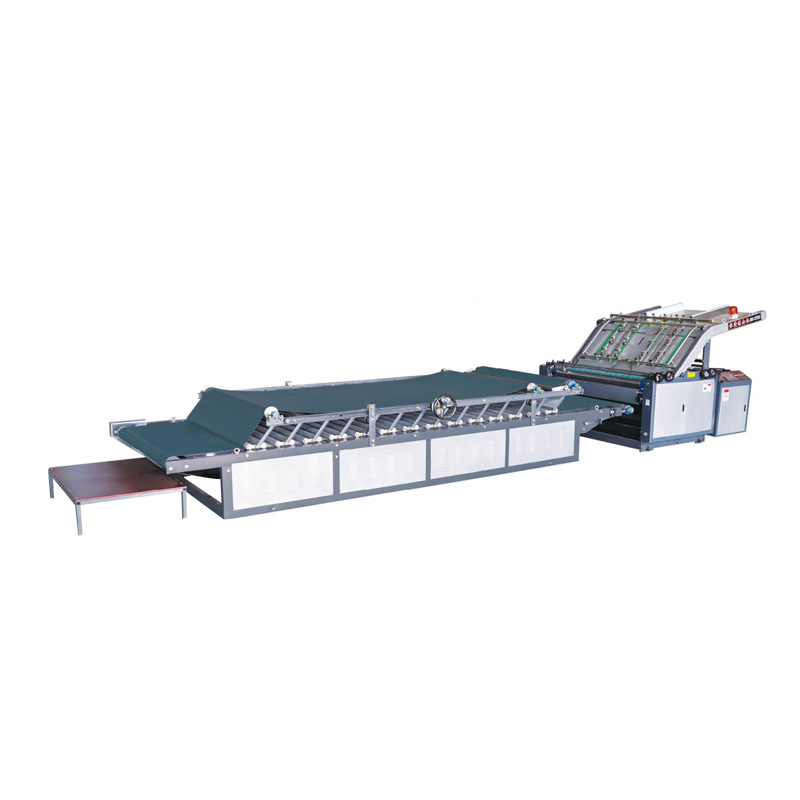

Understanding the Advantages and Functionality of PE Foam Sheet Extruders

In the realm of plastic processing machinery, the PE foam sheet extruder plays a pivotal role in the production of polyethylene foam sheets, which are widely utilized in various industries, including packaging, construction, and automotive. These extruders are designed to melt plastic resin and shape it into continuous foam sheets, showcasing a combination of lightweight, durability, and cushionin

2025/06

Maximizing Efficiency: Tips for Operating PE Foam Sheet Extrusion Machines

Maximizing Efficiency: Tips for Operating PE Foam Sheet Extrusion Machines Table of Contents 1. Introduction to PE Foam Sheet Extrusion 2. Understanding Extrusion Technology 3. The Importance of Efficiency in PE Foam Production 4. Best Operating Practices for PE Foam Sheet Extrusion 4.1 Material Selection for Optimal Performance 4.2 Temperature Con

2025/06

Understanding PE Foam Sheet Extruders: A Comprehensive Guide

--- In the realm of plastic processing machinery, the PE foam sheet extruder plays a pivotal role in the production of polyethylene foam sheets. These extruders are specifically designed for creating foam products that are lightweight, durable, and versatile in their applications. Understanding how these machines operate and the benefits they offer can help manufacturers optimize their production

2025/06

How to Choose the Right PE Foam Sheet Extruder for Your Production Needs

How to Choose the Right PE Foam Sheet Extruder for Your Production Needs When it comes to manufacturing PE foam sheets, selecting the right extruder is crucial for ensuring efficiency, quality, and profitability in your production process. With a plethora of options available, making an informed decision can seem daunting. This guide will equip you with the knowledge needed to choose the ideal PE

2025/06

Understanding HDPE Sheet Extrusion: A Comprehensive Guide for Professionals

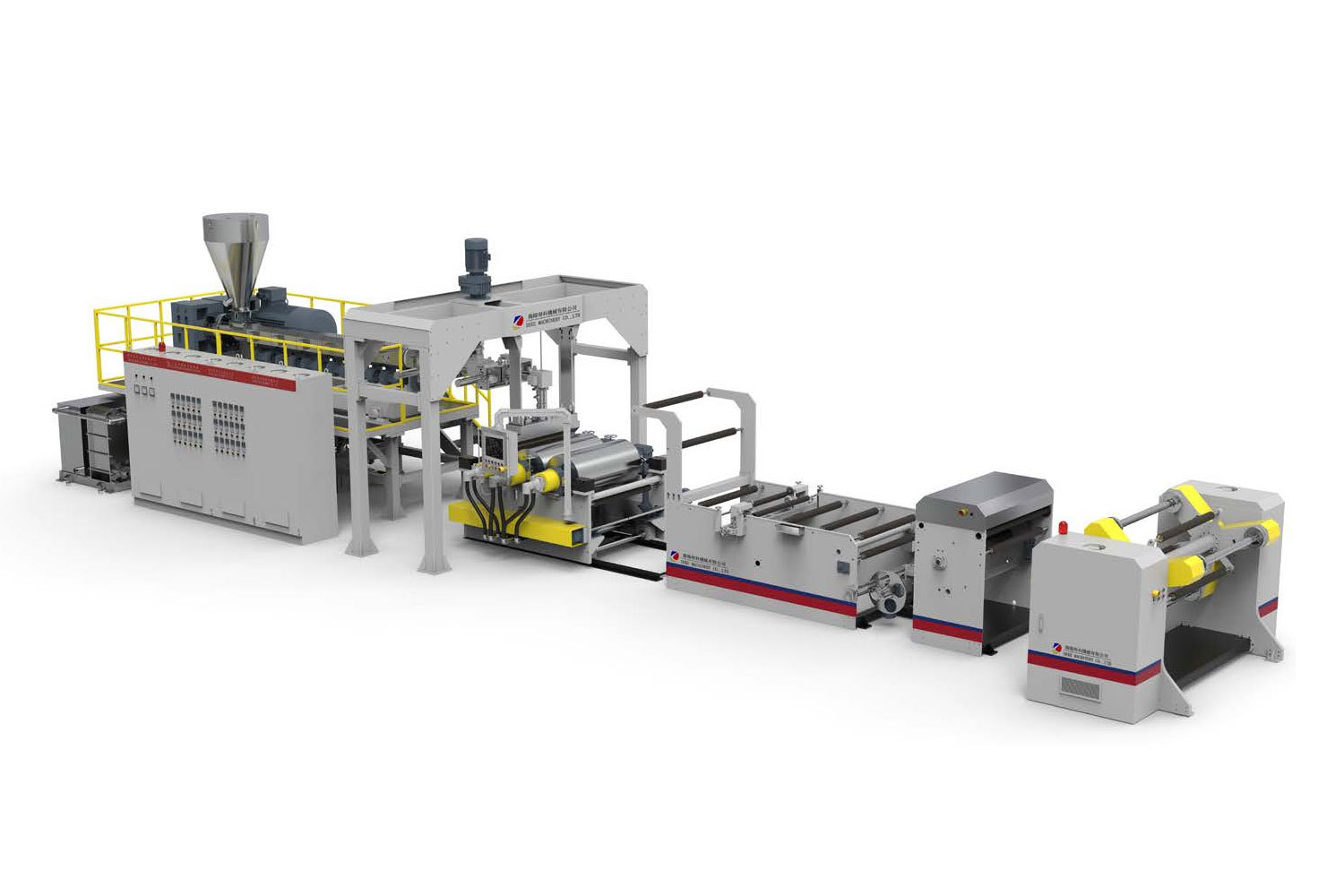

High-Density Polyethylene (HDPE) sheet extrusion is a pivotal process in the plastic manufacturing industry, particularly for those involved in the production of durable and versatile plastic sheets. This technique involves the continuous shaping of HDPE resin into flat sheets through a specialized extrusion process. Understanding the nuances of HDPE sheet extrusion can provide manufacturers with

2025/06

Why Choosing HDPE Sheet Extrusion Can Revolutionize Your Production Process

Why Choosing HDPE Sheet Extrusion Can Revolutionize Your Production Process Table of Contents Introduction to HDPE Sheet Extrusion The Benefits of HDPE Sheet Extrusion 1. Cost-Effectiveness 2. Durability and Strength 3. Environmental Impact 4. Customizability and Versatility Applications of HDPE Sheet Extrusion Understanding the Ex

2025/06

Understanding HDPE Sheet Extrusion: A Key Process in Plastic Manufacturing

HDPE (High-Density Polyethylene) sheet extrusion is a crucial process in the realm of plastic manufacturing, particularly when it comes to creating durable, versatile sheets used in a variety of applications. This method involves melting polyethylene resin and forcing it through a die to form sheets of consistent thickness—an essential step in producing materials that meet specific industry standa

RELATED INFORMATION

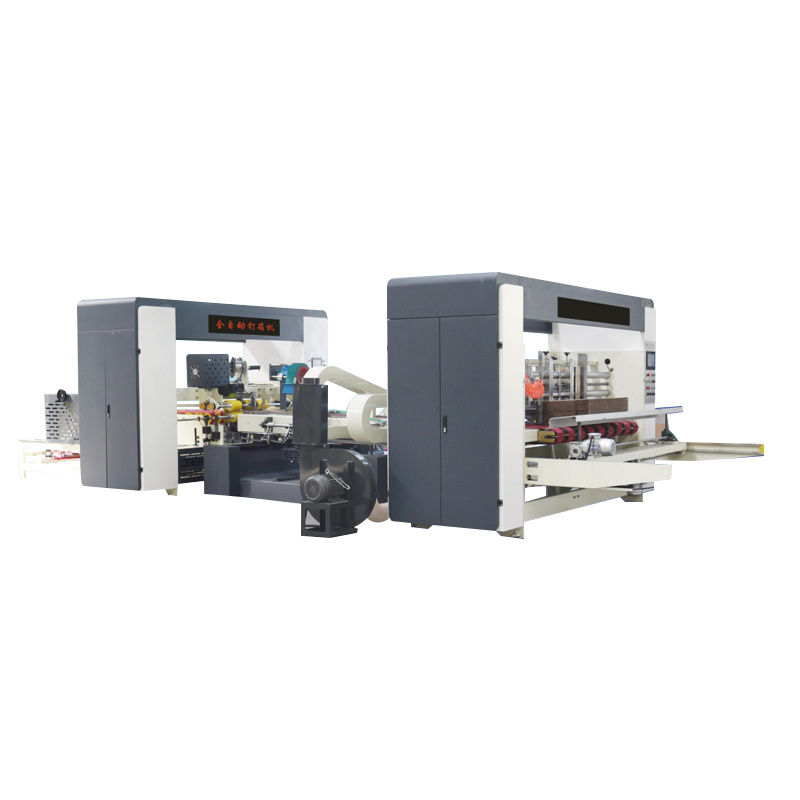

Understanding PET Sheet Extruder Machines: A Comprehensive Guide

PET sheet extruder machines are specialized equipment used in the plastic processing industry to produce sheets made from polyethylene terephthalate (PET). These machines play a crucial role in various applications, including packaging, automotive parts, and consumer goods. Understanding how these machines work, their components, and their applications can help manufacturers improve efficiency and

Exploring the Efficiency of PET Single Screw Extruders in Manufacturing

Exploring the Efficiency of PET Single Screw Extruders in Manufacturing Table of Contents 1. Introduction to PET Single Screw Extruders 2. The Importance of PET in the Manufacturing Process 3. Design and Mechanism of Single Screw Extruders 4. Efficiency Factors of PET Single Screw Extruders 5. Applications of PET Single Screw Extruders in Manufacturing 6. Maintenance and O