Understanding the Process and Benefits of PP HIPS Sheet Extrusion

2025-07

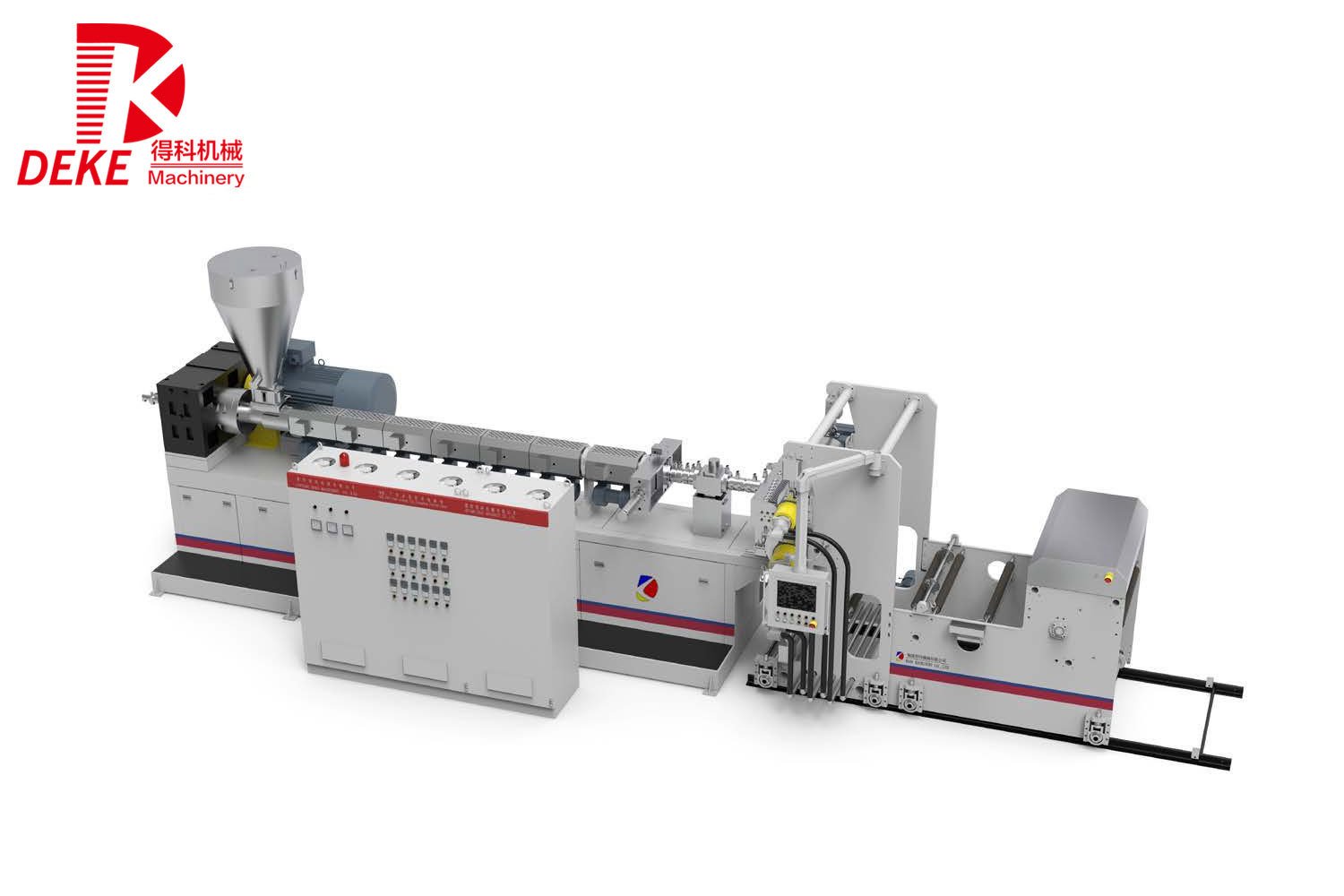

One of the key technical components of a PP HIPS sheet extruder is the screw design. The screw plays a vital role in the melting and mixing of the polymer, ensuring a homogeneous melt that contributes to the mechanical properties of the final sheet. The design can vary depending on the specific characteristics desired in the final product. For example, a high shear screw may be used to achieve better dispersion of additives, while a more conventional screw design might be employed for general-purpose applications.

Temperature control is another critical factor in the extrusion process. Different types of polymers require precise temperature settings to achieve optimal flow characteristics and sheet quality. The extruder is equipped with heating zones that are carefully regulated to maintain the correct temperature throughout the process. Proper temperature control not only enhances the quality of the final product but also minimizes the risk of thermal degradation, which can compromise the integrity of the material.

In addition to the mechanical aspects, the versatility of PP HIPS sheets makes them a popular choice in various industries. Their high impact resistance and ease of fabrication allow them to be used in applications such as signage, automotive interior parts, and consumer goods. The ability to modify the properties of PP HIPS sheets through the addition of various fillers and additives further broadens their scope of use.

Moreover, the efficiency of a PP HIPS sheet extruder contributes to the sustainability of the manufacturing process. By optimizing the extrusion parameters and minimizing waste, manufacturers can achieve higher production rates while reducing energy consumption. This aligns with the growing demand for environmentally friendly practices in the plastic industry.

In conclusion, the PP HIPS sheet extruder is an essential piece of equipment in the plastic processing sector, offering significant advantages in terms of product customization, efficiency, and sustainability. Understanding the intricacies of this technology can help manufacturers optimize their production processes and better meet the demands of their customers. As the industry continues to evolve, staying informed about advancements in extrusion technology will be crucial for maintaining a competitive edge.

RELATED INFORMATION

Understanding PET Sheet Extruder Machines: A Comprehensive Guide

PET sheet extruder machines are specialized equipment used in the plastic processing industry to produce sheets made from polyethylene terephthalate (PET). These machines play a crucial role in various applications, including packaging, automotive parts, and consumer goods. Understanding how these machines work, their components, and their applications can help manufacturers improve efficiency and

Exploring the Efficiency of PET Single Screw Extruders in Manufacturing

Exploring the Efficiency of PET Single Screw Extruders in Manufacturing Table of Contents 1. Introduction to PET Single Screw Extruders 2. The Importance of PET in the Manufacturing Process 3. Design and Mechanism of Single Screw Extruders 4. Efficiency Factors of PET Single Screw Extruders 5. Applications of PET Single Screw Extruders in Manufacturing 6. Maintenance and O