EVOH High Barrier Sheets: Enhancing Product Longevity Through Effective Extrusion

2025-07

EVOH High Barrier Sheets: Enhancing Product Longevity Through Effective Extrusion

Table of Contents

- 1. Introduction to EVOH High Barrier Sheets

- 2. What is EVOH?

- 3. Benefits of EVOH High Barrier Sheets

- 4. The Extrusion Process Explained

- 5. Applications of EVOH High Barrier Sheets

- 6. Sustainability Aspects of EVOH Materials

- 7. The Future of EVOH Technology

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to EVOH High Barrier Sheets

EVOH (Ethylene Vinyl Alcohol) high barrier sheets are a transformative solution in the realm of packaging and material science. Known for their exceptional barrier properties, these sheets play a critical role in extending the shelf life of perishable goods and enhancing product integrity. By preventing the permeation of gases, moisture, and other environmental factors, EVOH sheets ensure that products maintain their quality for longer periods. In this article, we delve deep into the benefits, applications, and the innovative extrusion processes that make EVOH high barrier sheets an essential component of modern manufacturing.

2. What is EVOH?

EVOH is a copolymer made from ethylene and vinyl alcohol, recognized for its superior barrier properties against oxygen and other gases. This unique structure allows EVOH to provide an impermeable shield that protects sensitive products from oxidation, spoilage, and contamination. The flexibility of its formulation enables manufacturers to tailor the properties of EVOH sheets according to specific requirements, making it a versatile choice in various industries, particularly in food packaging.

2.1 Properties of EVOH

The exceptional properties of EVOH include:

- **High Oxygen Barrier:** One of the most significant advantages of EVOH is its ability to block oxygen, which is crucial for extending the shelf life of food and pharmaceuticals.

- **Moisture Resistance:** EVOH sheets can effectively protect products from moisture, preventing degradation and spoilage.

- **Chemical Resistance:** These sheets are resistant to a range of chemicals, which safeguards the product's integrity.

- **Versatility:** EVOH can be processed into different forms, including films, sheets, and coatings, making it suitable for a variety of applications.

3. Benefits of EVOH High Barrier Sheets

The adoption of EVOH high barrier sheets offers numerous benefits, making them a preferred choice in packaging and manufacturing.

3.1 Extended Shelf Life

By creating a barrier against oxygen and moisture, EVOH sheets significantly enhance the shelf life of products. This is especially beneficial for perishable items such as food, pharmaceuticals, and cosmetics, where product quality is paramount.

3.2 Cost-Effectiveness

Using EVOH in packaging can lead to cost savings by reducing waste and minimizing spoilage. Manufacturers can also optimize their supply chain by extending the time products remain viable during storage and transport.

3.3 Improved Product Quality

EVOH sheets help maintain the flavor, aroma, and nutritional value of food items. This is particularly important in the food industry, where consumer preference leans towards fresh and high-quality products.

3.4 Customizable Solutions

The ability to tailor EVOH formulations allows manufacturers to create customized solutions that meet specific barrier requirements. This adaptability makes EVOH applicable in various industries, including food, pharmaceuticals, and electronics.

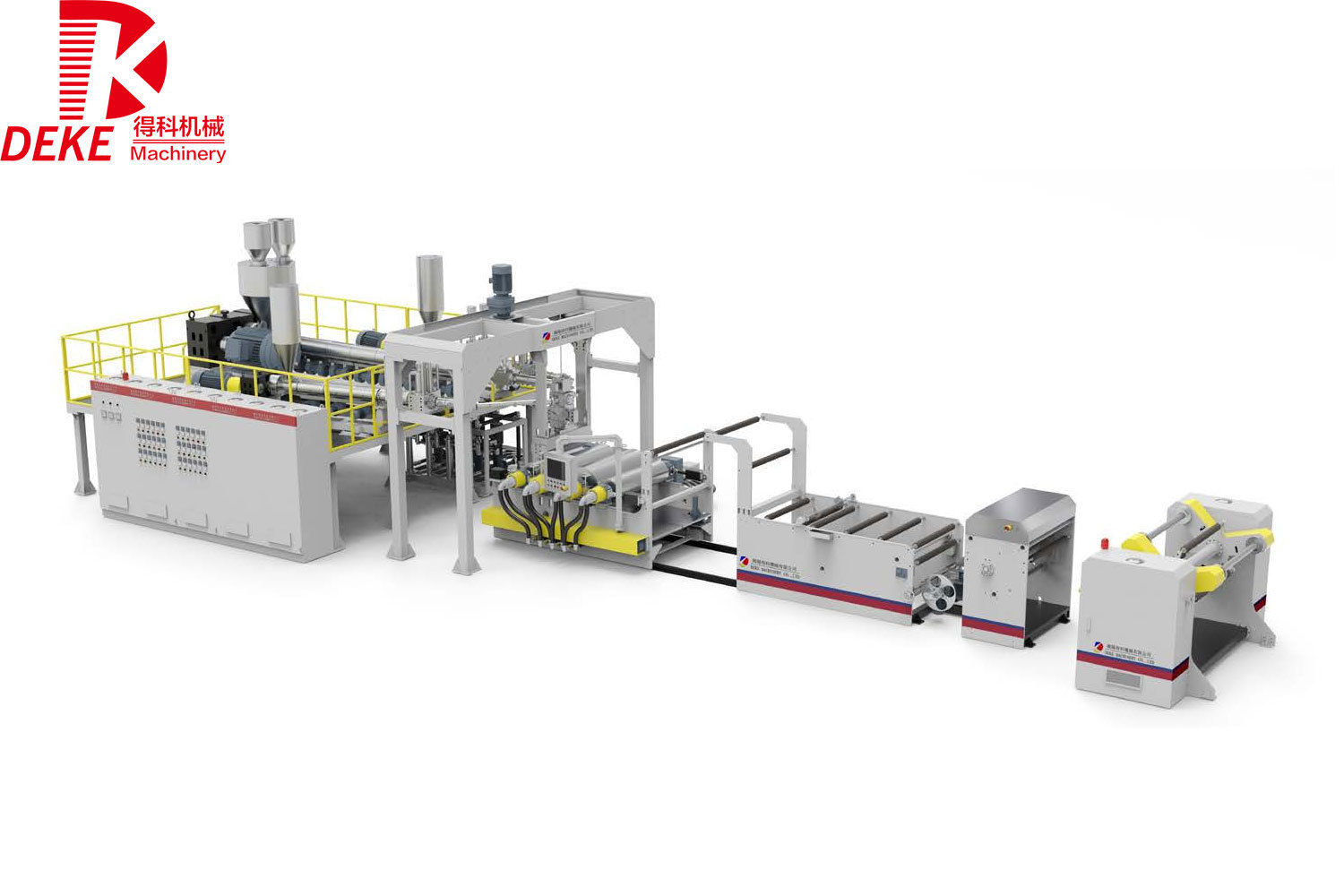

4. The Extrusion Process Explained

The production of EVOH high barrier sheets involves a complex extrusion process that ensures uniformity and quality. Understanding this process is crucial for manufacturers looking to leverage the benefits of EVOH.

4.1 What is Extrusion?

Extrusion is a manufacturing process that involves forcing material through a die to create a desired shape. In the case of EVOH sheets, the material is heated and then extruded through a flat die to form thin, uniform sheets.

4.2 Steps in the Extrusion Process

- **Material Preparation:** The EVOH resin is mixed with additives to enhance its properties.

- **Melting:** The mixture is heated to a specific temperature to melt the resin.

- **Extrusion:** The molten material is forced through a die, creating a flat sheet.

- **Cooling and Solidification:** The extruded sheet is cooled and solidified before being rolled for further processing.

4.3 Quality Control

Quality control is an essential aspect of the extrusion process. Regular testing for thickness, barrier properties, and overall integrity ensures that the final product meets industry standards and customer expectations.

5. Applications of EVOH High Barrier Sheets

EVOH high barrier sheets are versatile and find applications in various sectors, reflecting their importance in the modern manufacturing landscape.

5.1 Food Packaging

EVOH sheets are widely used in food packaging due to their ability to prolong shelf life and maintain product integrity. They are commonly found in vacuum-sealed packages, pouches, and containers for meats, cheeses, and other perishables.

5.2 Pharmaceutical Packaging

In the pharmaceutical industry, maintaining product efficacy and safety is crucial. EVOH high barrier sheets protect sensitive medications from moisture and oxygen, ensuring they remain effective for longer periods.

5.3 Cosmetics and Personal Care Products

Cosmetic products often contain sensitive ingredients that can degrade over time. EVOH sheets provide a protective barrier, preserving the quality and effectiveness of these products.

6. Sustainability Aspects of EVOH Materials

As sustainability becomes increasingly important, the use of EVOH materials aligns with eco-friendly practices in packaging.

6.1 Recyclability

EVOH sheets can be recycled alongside other plastics, reducing waste and contributing to a circular economy. This aspect makes them a more environmentally friendly option compared to traditional packaging materials.

6.2 Reduced Food Waste

By extending the shelf life of perishable products, EVOH sheets help reduce food waste. This aligns with global efforts to promote sustainability and responsible consumption.

7. The Future of EVOH Technology

The future of EVOH technology appears promising, with ongoing research and development focused on enhancing its properties and applications.

7.1 Innovations in Material Science

Emerging technologies in material science are expected to lead to more advanced EVOH formulations, offering even better barrier properties and customizable solutions for various industries.

7.2 Integration with Smart Packaging

The integration of EVOH sheets with smart packaging technologies presents exciting opportunities. This combination can provide real-time monitoring of product conditions, enhancing safety and quality assurance.

8. Frequently Asked Questions

8.1 What makes EVOH a preferred choice for food packaging?

EVOH is preferred for food packaging due to its exceptional oxygen barrier properties, which help prolong shelf life and maintain product quality.

8.2 Can EVOH sheets be recycled?

Yes, EVOH sheets can be recycled with other plastics, contributing to sustainable practices in packaging.

8.3 What industries utilize EVOH high barrier sheets?

EVOH high barrier sheets are utilized in various industries, including food, pharmaceuticals, cosmetics, and electronics.

8.4 How does the extrusion process affect EVOH sheet quality?

The extrusion process is critical for ensuring uniform thickness, barrier properties, and overall integrity of EVOH sheets, which directly impacts their performance.

8.5 Are there any innovations expected in EVOH technology?

Yes, ongoing research aims to develop advanced EVOH formulations and integrate them with smart packaging solutions to enhance their functionality and application range.

9. Conclusion

EVOH high barrier sheets represent a significant advancement in packaging technology, providing solutions that enhance product longevity and quality. By understanding the benefits, applications, and the extrusion process behind these materials, manufacturers can leverage their properties to meet the evolving demands of consumers and industries alike. As we look toward the future, EVOH technology will continue to play a crucial role in sustainable practices, making it an invaluable asset in modern manufacturing.

RELATED INFORMATION

Understanding PET Sheet Extruder Machines: A Comprehensive Guide

PET sheet extruder machines are specialized equipment used in the plastic processing industry to produce sheets made from polyethylene terephthalate (PET). These machines play a crucial role in various applications, including packaging, automotive parts, and consumer goods. Understanding how these machines work, their components, and their applications can help manufacturers improve efficiency and

Exploring the Efficiency of PET Single Screw Extruders in Manufacturing

Exploring the Efficiency of PET Single Screw Extruders in Manufacturing Table of Contents 1. Introduction to PET Single Screw Extruders 2. The Importance of PET in the Manufacturing Process 3. Design and Mechanism of Single Screw Extruders 4. Efficiency Factors of PET Single Screw Extruders 5. Applications of PET Single Screw Extruders in Manufacturing 6. Maintenance and O