Unlocking the Potential of EVOH High Barrier Sheet Extruders in Plastic Processing

2025-07

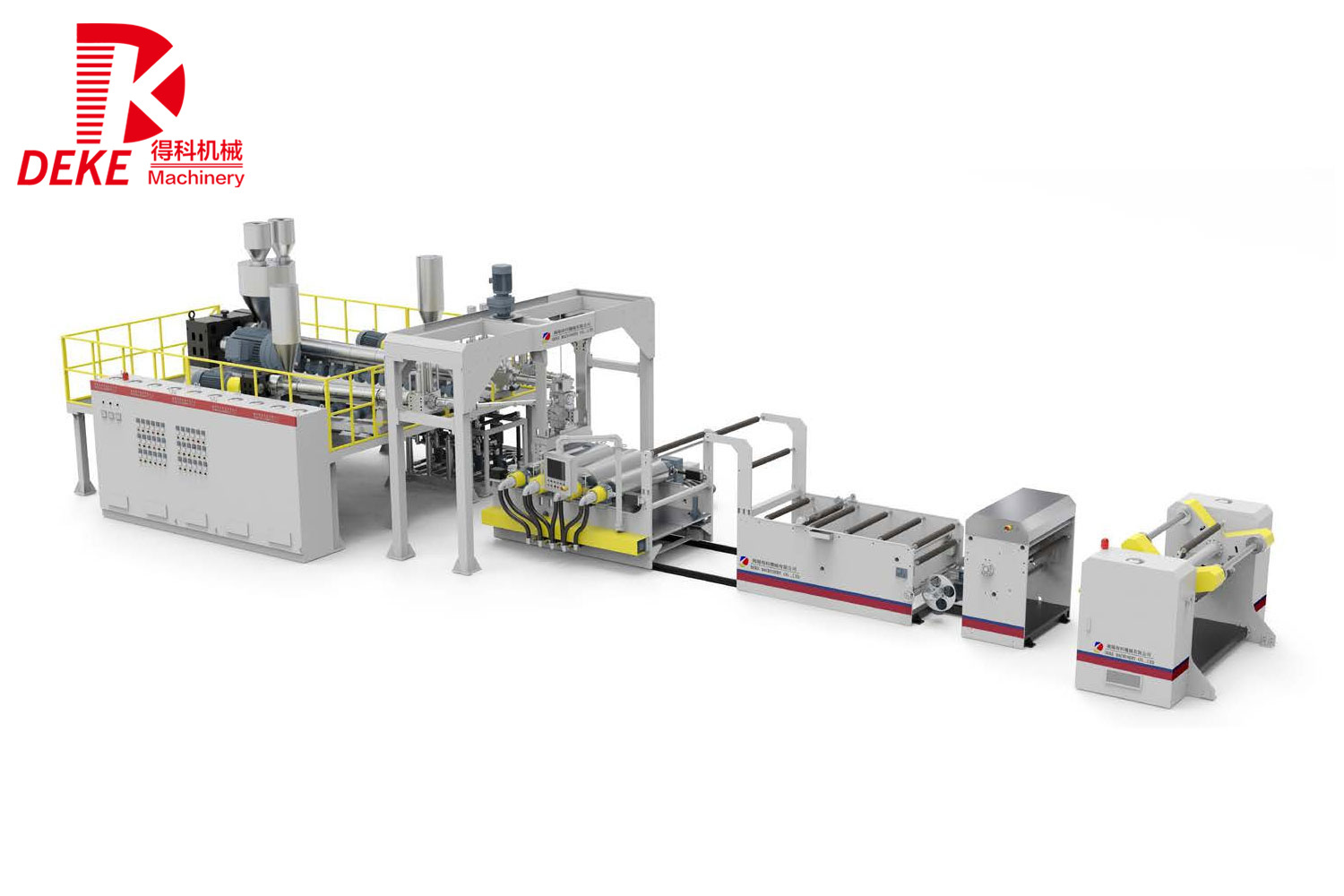

The operation of an EVOH high barrier sheet extruder involves a series of technical processes that begin with the careful selection of raw materials. The extrusion process utilizes controlled temperatures and pressures to melt the EVOH resin, which is then shaped into sheets using a die. The thickness and width of the sheets can be customized to meet specific client requirements or application needs.

One of the primary advantages of using EVOH in sheet extrusion is its ability to significantly extend the shelf life of perishable products. By minimizing oxygen transmission rates, EVOH sheets help to prevent spoilage and maintain the quality of food items. This is increasingly important in today’s market, where consumers expect fresher products and manufacturers seek to reduce waste and improve sustainability.

Moreover, EVOH high barrier sheets are not only beneficial for food packaging but also play a vital role in other industries. For instance, in the pharmaceutical sector, these sheets help protect sensitive medications from environmental factors, ensuring their efficacy and safety. Additionally, in electronic packaging, EVOH barriers can prevent moisture ingress, thereby enhancing product reliability and longevity.

Furthermore, advancements in extrusion technology have led to improved production rates and energy efficiency in EVOH sheet manufacturing. Modern extruders often incorporate features such as multi-layer capabilities, allowing for the creation of composite materials that combine multiple polymers for enhanced performance. This innovation not only maximizes the barrier properties of EVOH but also allows for cost-effective production processes.

In conclusion, EVOH high barrier sheet extruders represent a significant advancement in the plastics processing industry. By providing exceptional barrier properties and versatility across various applications, these extruders contribute to higher product quality and increased consumer satisfaction. As technology continues to evolve, the potential for EVOH applications is set to expand, making it a vital area for businesses looking to enhance their packaging solutions while meeting market demands. Investing in high-quality extrusion equipment will ensure that manufacturers can leverage these benefits and remain competitive in the ever-evolving landscape of plastic processing.

Previous Page:

RELATED INFORMATION

Understanding PET Sheet Extruder Machines: A Comprehensive Guide

PET sheet extruder machines are specialized equipment used in the plastic processing industry to produce sheets made from polyethylene terephthalate (PET). These machines play a crucial role in various applications, including packaging, automotive parts, and consumer goods. Understanding how these machines work, their components, and their applications can help manufacturers improve efficiency and

Exploring the Efficiency of PET Single Screw Extruders in Manufacturing

Exploring the Efficiency of PET Single Screw Extruders in Manufacturing Table of Contents 1. Introduction to PET Single Screw Extruders 2. The Importance of PET in the Manufacturing Process 3. Design and Mechanism of Single Screw Extruders 4. Efficiency Factors of PET Single Screw Extruders 5. Applications of PET Single Screw Extruders in Manufacturing 6. Maintenance and O