2025/06

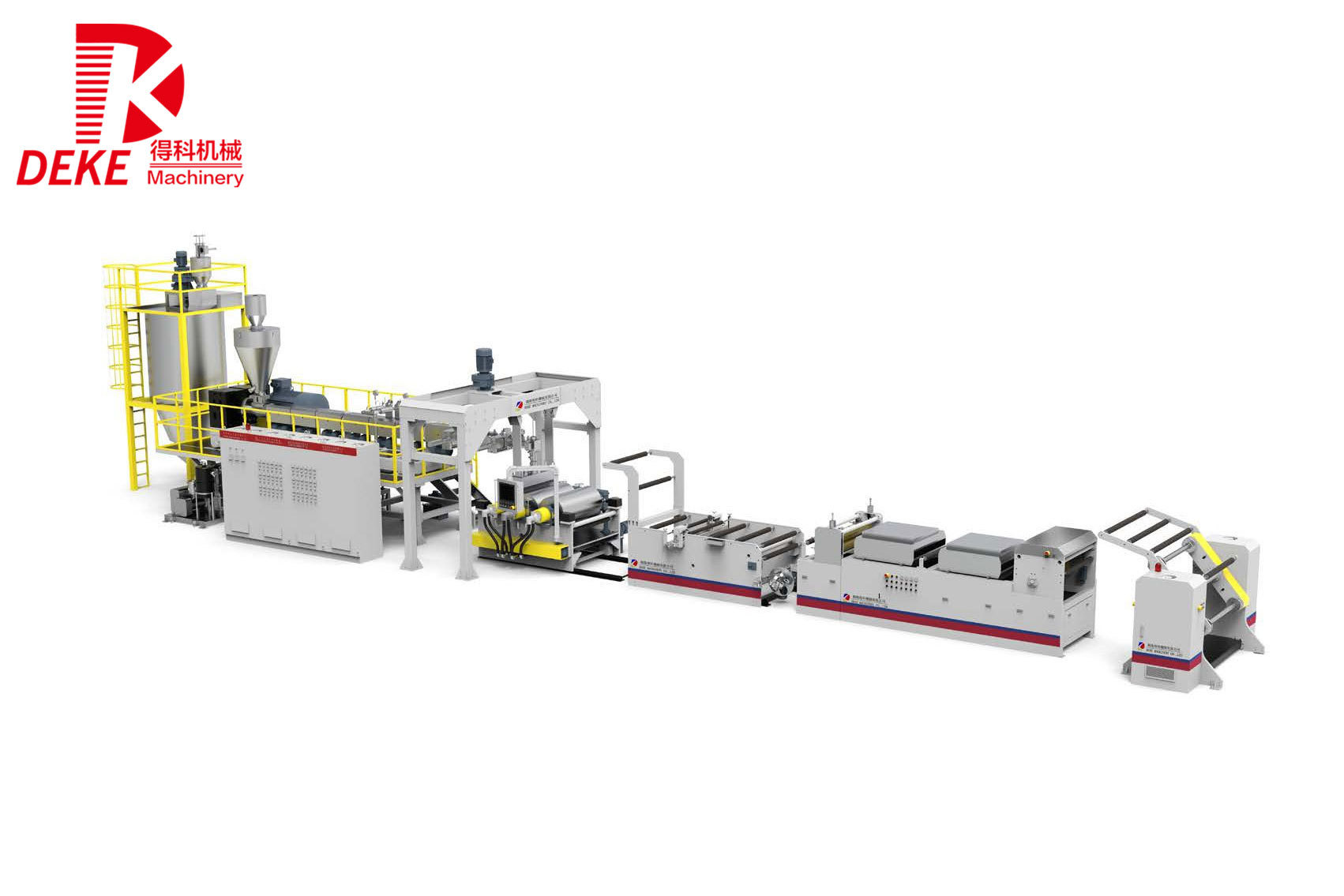

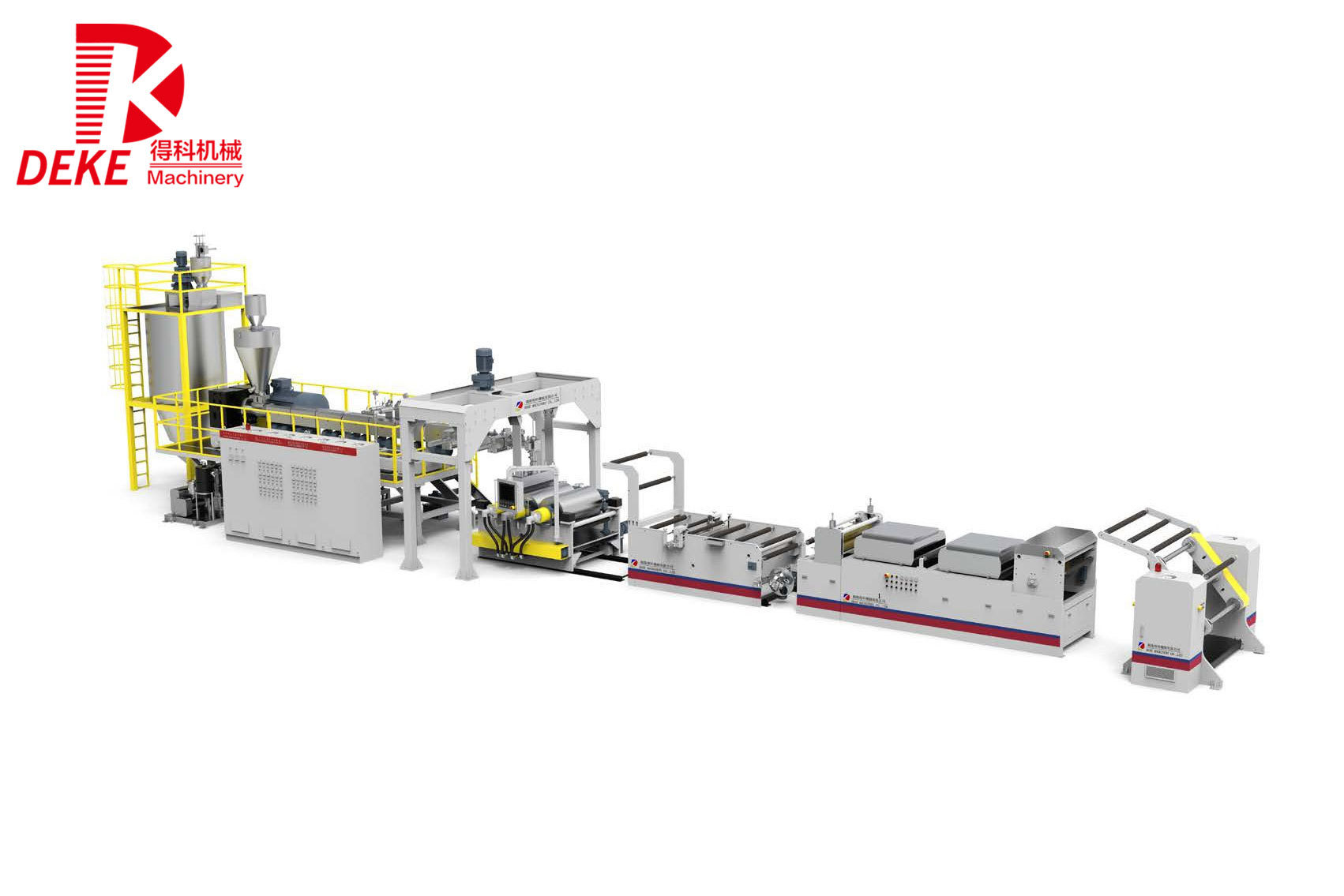

Unlocking the Benefits of HDPE Sheet Extrusion in Modern Manufacturing

Unlocking the Benefits of HDPE Sheet Extrusion in Modern Manufacturing Table of Contents Introduction to HDPE Sheet Extrusion What is HDPE and Its Properties? Understanding the HDPE Extrusion Process Advantages of HDPE Sheet Extrusion in Manufacturing Applications of HDPE Sheets Across Industries Sustainability and Environmental Impact of HDPE The Future of HDPE Sheet Extrusion Co

2025/06

Understanding the Benefits and Applications of Small Twin Screw Extruders

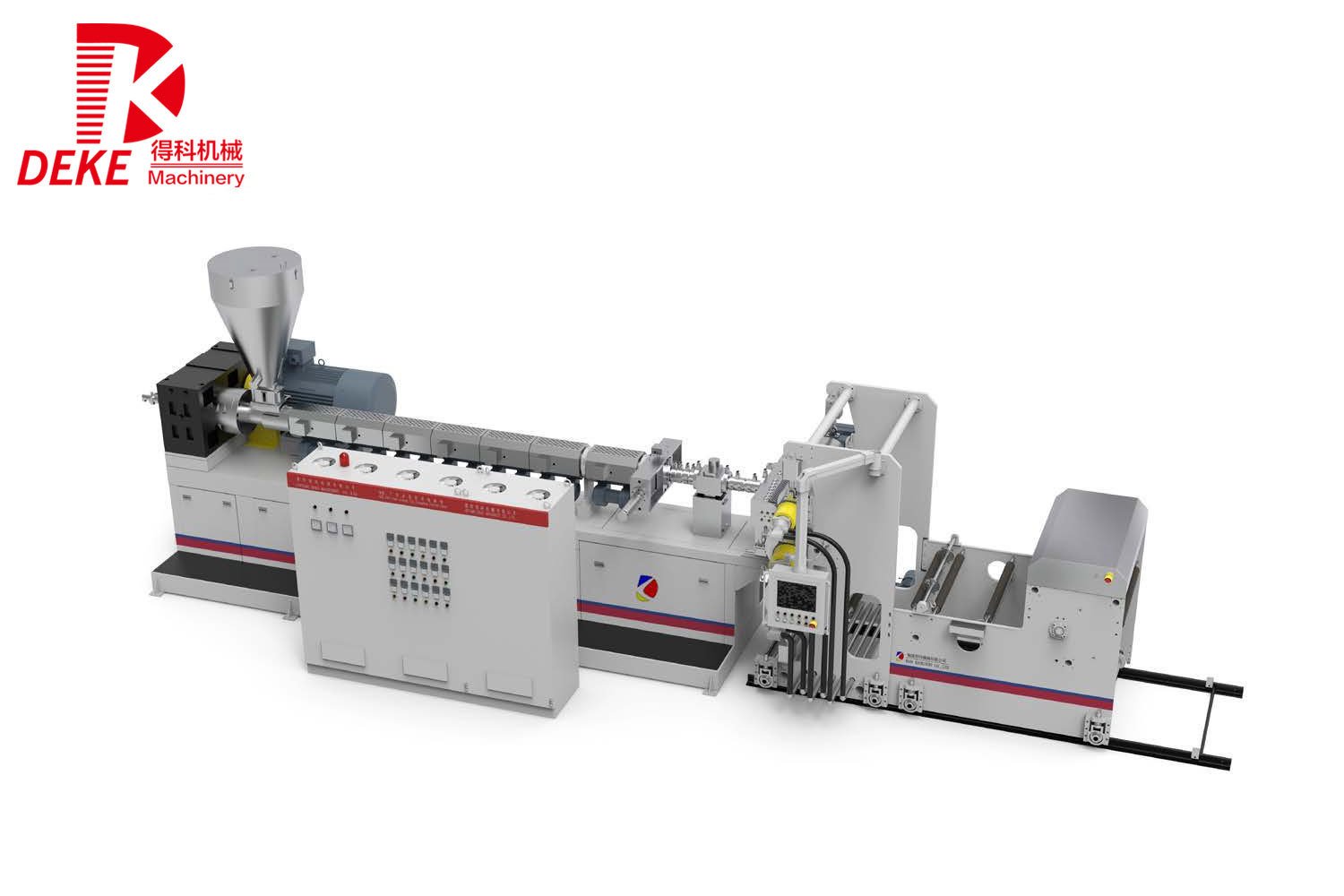

In the realm of plastic processing machinery, small twin screw extruders have gained considerable recognition for their versatility and efficiency. These machines are characterized by two parallel screws that rotate within a barrel, allowing for the precise mixing, melting, and forming of various plastic materials. Their design enables better control over the extrusion process, making them ideal f

2025/06

The Benefits of Using Advanced Control Systems in Small Twin Screw Extruders

The Benefits of Using Advanced Control Systems in Small Twin Screw Extruders Introduction to Small Twin Screw Extruders Small twin screw extruders play a pivotal role in the plastic manufacturing industry. They are essential for various applications such as compounding, mixing, and polymer processing. The effectiveness of these machines influences the quality of the final product and overall p

2025/06

Understanding the Benefits and Applications of Small Twin Screw Extruders

Small twin screw extruders are increasingly becoming an essential piece of equipment in the plastic processing machinery sector. These advanced machines consist of two intermeshing screws that rotate within a barrel, providing enhanced mixing and compounding capabilities. Their design enables a high degree of flexibility and efficiency, making them suitable for a wide range of applications in the

2025/06

How to Optimize Your Production Line with Small Twin Screw Extruders

How to Optimize Your Production Line with Small Twin Screw Extruders Introduction to Small Twin Screw Extruders In today's competitive manufacturing landscape, the efficiency of the production line plays a critical role in determining the overall success of a company. **Small twin screw extruders** are an innovative solution that can significantly enhance production capabilities. They are part

2025/06

Understanding the Versatility of Conical Twin Screws in Plastic Extrusion

In the realm of plastic processing machinery, the conical twin screw is a critical component, especially in the manufacturing of plastic extruders. These screws are engineered to enhance the efficiency and versatility of the extrusion process, enabling a wide range of applications in the plastics industry. The conical twin screw configuration consists of two screws that are arranged in a helical f

2025/06

How Conical Twin Screw Technology Revolutionizes Extrusion Machinery

How Conical Twin Screw Technology Revolutionizes Extrusion Machinery Table of Contents Introduction to Conical Twin Screw Technology Understanding Extrusion Machinery The Principle of Conical Twin Screw Technology Advantages of Conical Twin Screw Extruders Applications in Various Industries Challenges and Solutions in Implementation Future Trends in E

2025/06

Understanding Conical Twin Screws: A Key Component in Plastic Extrusion Machinery

Conical twin screws are designed for a wide range of applications in the plastic processing industry, particularly in the manufacturing of plastic extrusion machinery. These screws consist of two intermeshing helical threads, which are set at an angle, allowing for efficient material transportation and processing. One of the primary advantages of conical twin screws is their ability to handle vari

2025/06

Exploring the Advantages of Conical Twin Screw in Plastic Processing

Exploring the Advantages of Conical Twin Screw in Plastic Processing Table of Contents 1. Introduction to Conical Twin Screw Extruders 2. Advantages of Conical Twin Screw Technology 2.1 Superior Mixing Capabilities 2.2 Increased Processing Efficiency 2.3 Energy Savings 2.4 Enhanced Product Quality

2025/06

The Essential Guide to Conical Twin Screw Extruders in Plastic Processing

Conical twin screw extruders are vital in the plastic processing machinery sector, particularly in enhancing the efficiency and quality of material processing. These extruders utilize two intermeshing screws that are typically set at an angle, or "conical" shape, which contributes to their unique processing capabilities. The design is specifically engineered to facilitate effective mixing, compoun

RELATED INFORMATION

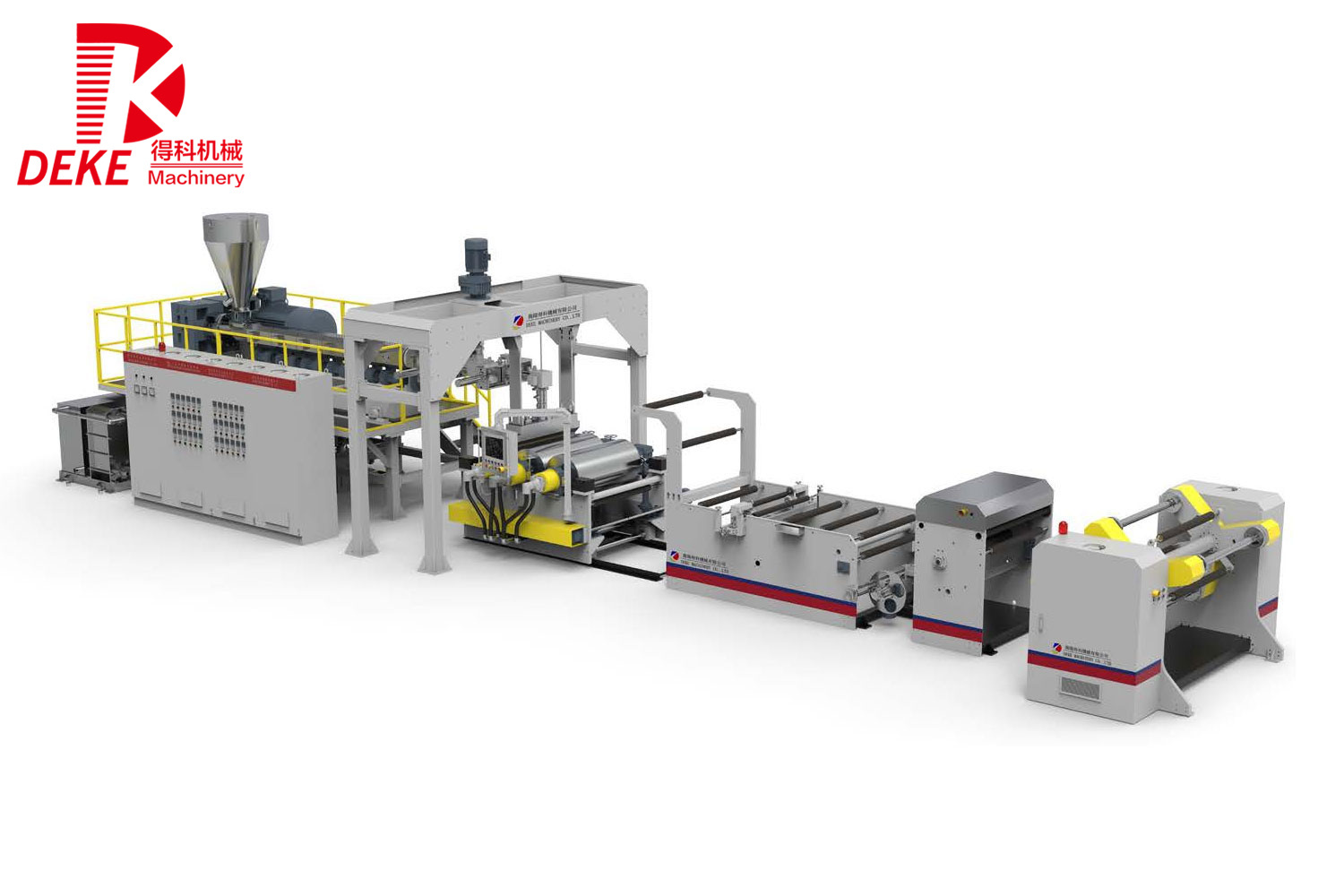

Understanding PET Sheet Extruder Machines: A Comprehensive Guide

PET sheet extruder machines are specialized equipment used in the plastic processing industry to produce sheets made from polyethylene terephthalate (PET). These machines play a crucial role in various applications, including packaging, automotive parts, and consumer goods. Understanding how these machines work, their components, and their applications can help manufacturers improve efficiency and

Exploring the Efficiency of PET Single Screw Extruders in Manufacturing

Exploring the Efficiency of PET Single Screw Extruders in Manufacturing Table of Contents 1. Introduction to PET Single Screw Extruders 2. The Importance of PET in the Manufacturing Process 3. Design and Mechanism of Single Screw Extruders 4. Efficiency Factors of PET Single Screw Extruders 5. Applications of PET Single Screw Extruders in Manufacturing 6. Maintenance and O