Understanding the Benefits and Functionality of Twin Screw Extrusion Lines

2025-07

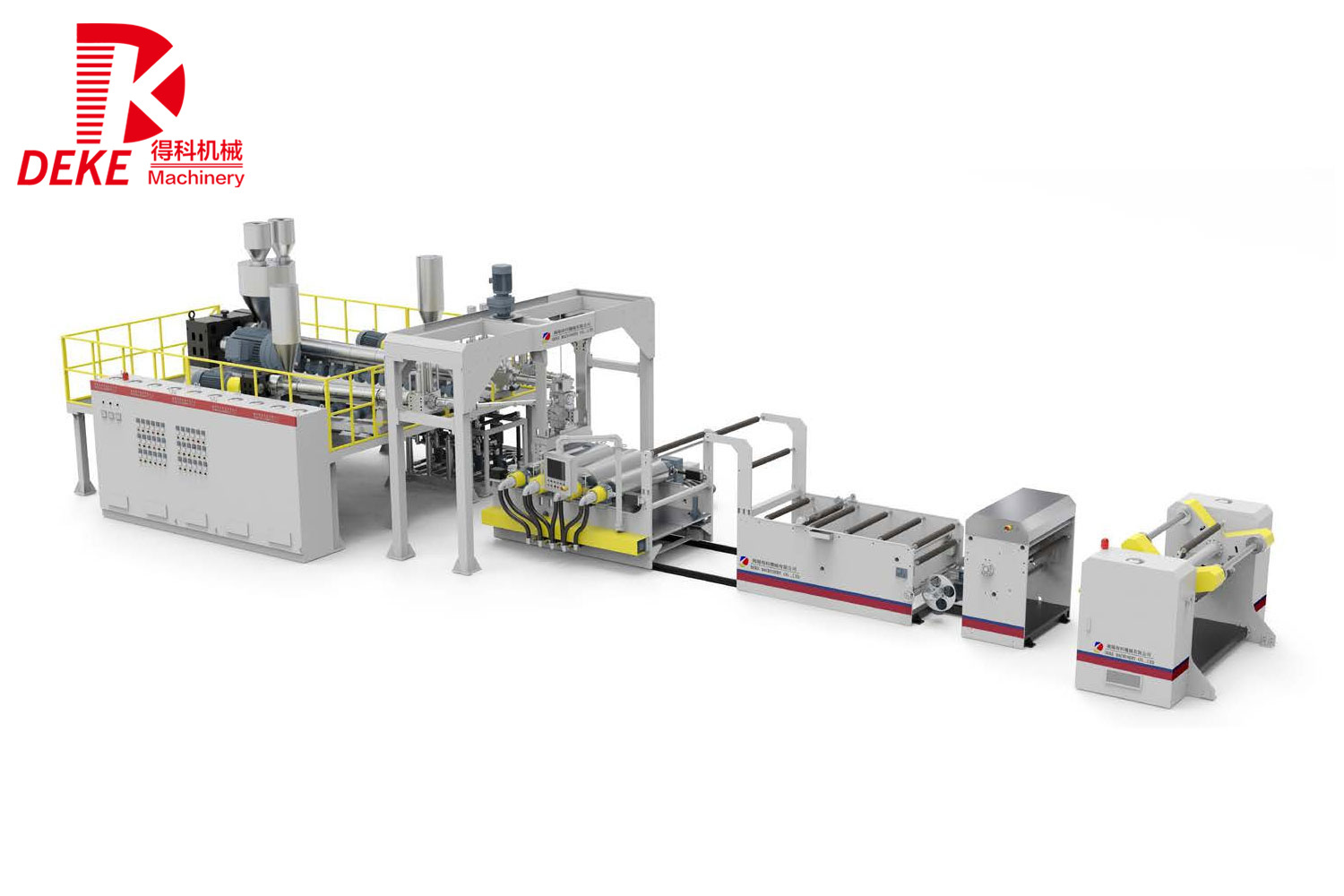

Twin screw extrusion lines are a vital component in the realm of plastic processing machinery, specifically designed to enhance the mixing, compounding, and extrusion of various materials. Unlike single screw extruders, twin screw extruders feature two intermeshing screws that rotate within a barrel, facilitating superior blending and material handling.

One of the primary advantages of a twin screw extrusion line is its ability to achieve a high level of mixing and uniformity. The design of the screws allows for a more effective shear force, which is essential for processing materials with varying viscosities. This characteristic is particularly beneficial when dealing with complex formulations that require precise ratios and consistent quality. The intermeshing nature of the screws promotes continuous material movement, ensuring that every particle is subjected to similar processing conditions.

Moreover, twin screw extruders offer significant flexibility in their operational capabilities. They can process a wide range of materials, including thermoplastics, thermosets, and even biodegradable composites. This versatility makes them an ideal choice for manufacturers looking to diversify their product lines or adapt to changing market demands. The ability to switch between different materials with minimal downtime can greatly enhance overall productivity.

In addition to their mixing capabilities, twin screw extrusion lines are equipped with the technology needed for effective compounding. Compounding is the process of combining various raw materials to create a finished product with desired properties. Twin screw extruders effectively incorporate additives, fillers, and colorants into the base polymer, resulting in enhanced mechanical properties and aesthetic appeal. This ability to tailor material properties is a significant advantage for manufacturers seeking to innovate or improve existing products.

Another noteworthy feature of twin screw extrusion lines is their capability for real-time process monitoring and control. Modern systems often come equipped with advanced automation and control technologies that allow operators to monitor parameters such as temperature, pressure, and screw speed. This data-driven approach ensures consistency and quality in production, reducing the risk of defects and waste.

Energy efficiency is increasingly becoming a focus in manufacturing processes, and twin screw extruders are designed with this in mind. They typically consume less energy compared to traditional single screw extruders, making them a more sustainable option for manufacturers. By optimizing the extrusion process, businesses can not only reduce operational costs but also contribute to environmental sustainability.

In conclusion, twin screw extrusion lines play a crucial role in the plastic processing machinery industry, offering enhanced mixing capabilities, flexibility, and efficiency. Their ability to accommodate various materials and real-time monitoring technology positions them as a preferred choice for manufacturers aiming to produce high-quality products while minimizing waste and energy consumption. Understanding the functionality and benefits of these machines can empower businesses to make informed decisions as they navigate the complexities of modern manufacturing.

RELATED INFORMATION

Why Choosing a Twin Screw Compounder Can Transform Your Plastic Manufacturing

Why Choosing a Twin Screw Compounder Can Transform Your Plastic Manufacturing Manufacturing in the plastic industry involves intricate processes that require precision, efficiency, and innovation. Among the various technologies available, the twin screw compounder stands out as a transformative solution that can redefine how plastic products are made. This article delves into the numerous advantag

Understanding the Benefits and Functionality of Twin Screw Extrusion Lines

--- Twin screw extrusion lines are a vital component in the realm of plastic processing machinery, specifically designed to enhance the mixing, compounding, and extrusion of various materials. Unlike single screw extruders, twin screw extruders feature two intermeshing screws that rotate within a barrel, facilitating superior blending and material handling. One of the primary advantages of a twin