Understanding the Versatility of Conical Twin Screws in Plastic Extrusion

2025-06

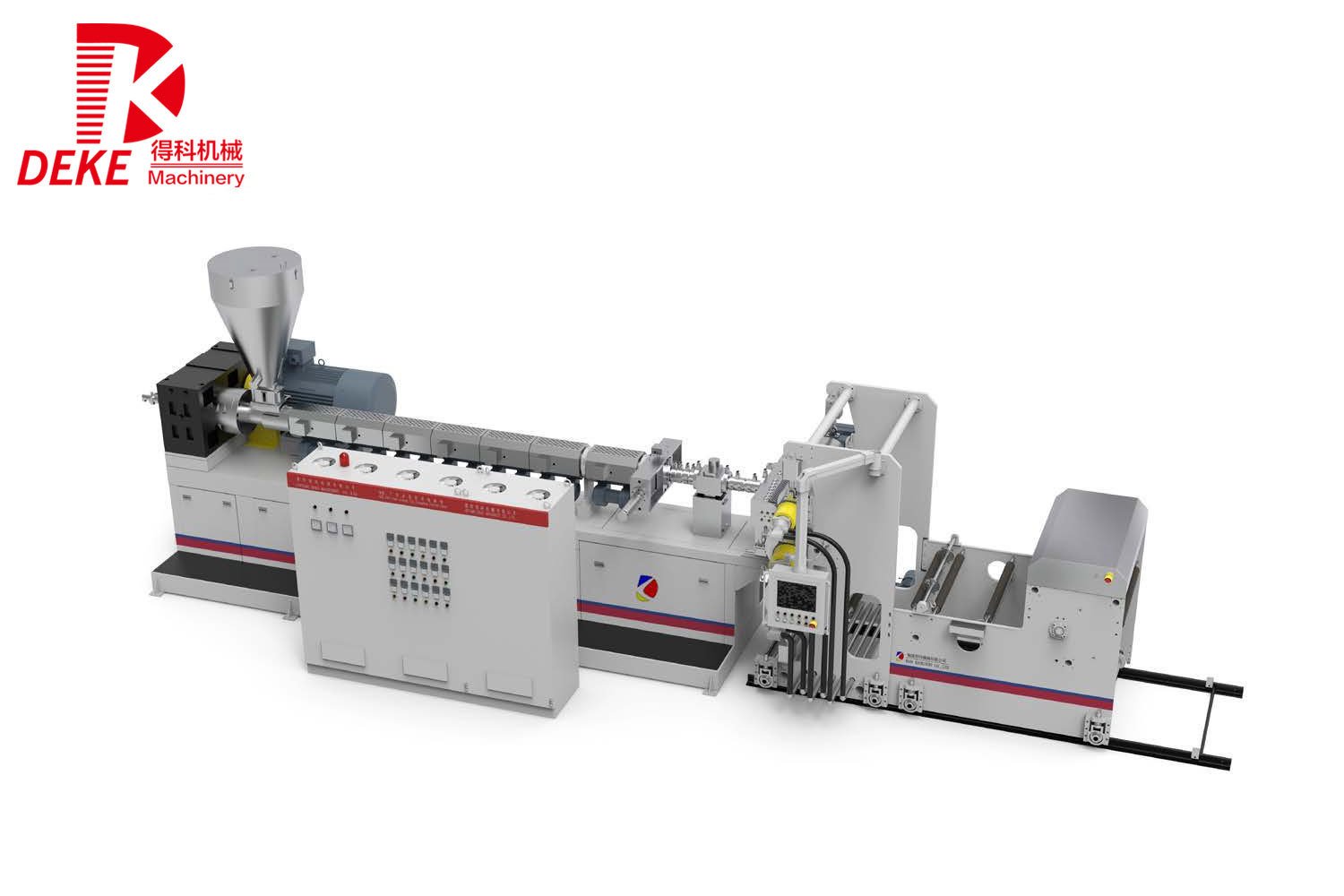

The conical twin screw configuration consists of two screws that are arranged in a helical fashion, tapering along their length. This unique design allows for improved material conveyance and mixing compared to traditional single-screw extruders. The screws rotate in opposite directions, creating a highly effective process for melting, homogenizing, and pumping the polymer material through the extruder.

One of the primary benefits of conical twin screws is their ability to handle various materials, including thermoplastics and thermosetting plastics. The versatility of these screws makes them suitable for processing a wide array of materials, from rigid to flexible plastics, which is particularly advantageous for manufacturers aiming to adapt to changing market demands. Additionally, the design allows for better control over the temperature and pressure within the extruder, leading to higher quality end products.

Another significant advantage of conical twin screws is their mixing capabilities. The intermeshing design promotes thorough mixing of additives, fillers, and colorants with the base polymer. This is crucial for producing customized materials that meet specific performance requirements. For instance, the incorporation of flame retardants, UV stabilizers, or other functional additives can be executed with precision, ensuring uniform dispersion throughout the material.

Furthermore, conical twin screw extruders are known for their energy efficiency. The design minimizes the shear forces exerted on the material, which translates to lower energy consumption. This not only reduces operational costs but also contributes to a more sustainable manufacturing process, aligning with the growing emphasis on environmental responsibility in the plastics industry.

In conclusion, the conical twin screw is an indispensable asset in plastic extrusion technology. Its ability to effectively process a wide range of materials while ensuring high-quality output and energy efficiency positions it as a preferred choice for manufacturers. As the plastics industry evolves, understanding the functionality and advantages of conical twin screws will be essential for professionals aiming to optimize their production processes and meet the diverse needs of the market. Embracing this technology can lead to innovative solutions and improved competitiveness in the field of plastic manufacturing.

RELATED INFORMATION

Understanding PET Sheet Extruder Machines: A Comprehensive Guide

PET sheet extruder machines are specialized equipment used in the plastic processing industry to produce sheets made from polyethylene terephthalate (PET). These machines play a crucial role in various applications, including packaging, automotive parts, and consumer goods. Understanding how these machines work, their components, and their applications can help manufacturers improve efficiency and

Exploring the Efficiency of PET Single Screw Extruders in Manufacturing

Exploring the Efficiency of PET Single Screw Extruders in Manufacturing Table of Contents 1. Introduction to PET Single Screw Extruders 2. The Importance of PET in the Manufacturing Process 3. Design and Mechanism of Single Screw Extruders 4. Efficiency Factors of PET Single Screw Extruders 5. Applications of PET Single Screw Extruders in Manufacturing 6. Maintenance and O