Understanding the Benefits and Applications of Small Twin Screw Extruders

2025-06

One of the primary advantages of small twin screw extruders is their exceptional ability to handle a variety of materials, including thermoplastics, thermosets, and bio-based polymers. The intermeshing screw configuration ensures thorough mixing, which is crucial for achieving uniform material properties. This feature is particularly beneficial in applications requiring the incorporation of additives or fillers, as it enables a homogeneous blend that can improve the performance characteristics of the final product.

Another significant benefit of small twin screw extruders is their capacity for temperature control and precision processing. The design allows for effective heat transfer, which is vital when working with heat-sensitive materials. This capability ensures that materials maintain their integrity throughout the extrusion process, leading to higher quality outputs.

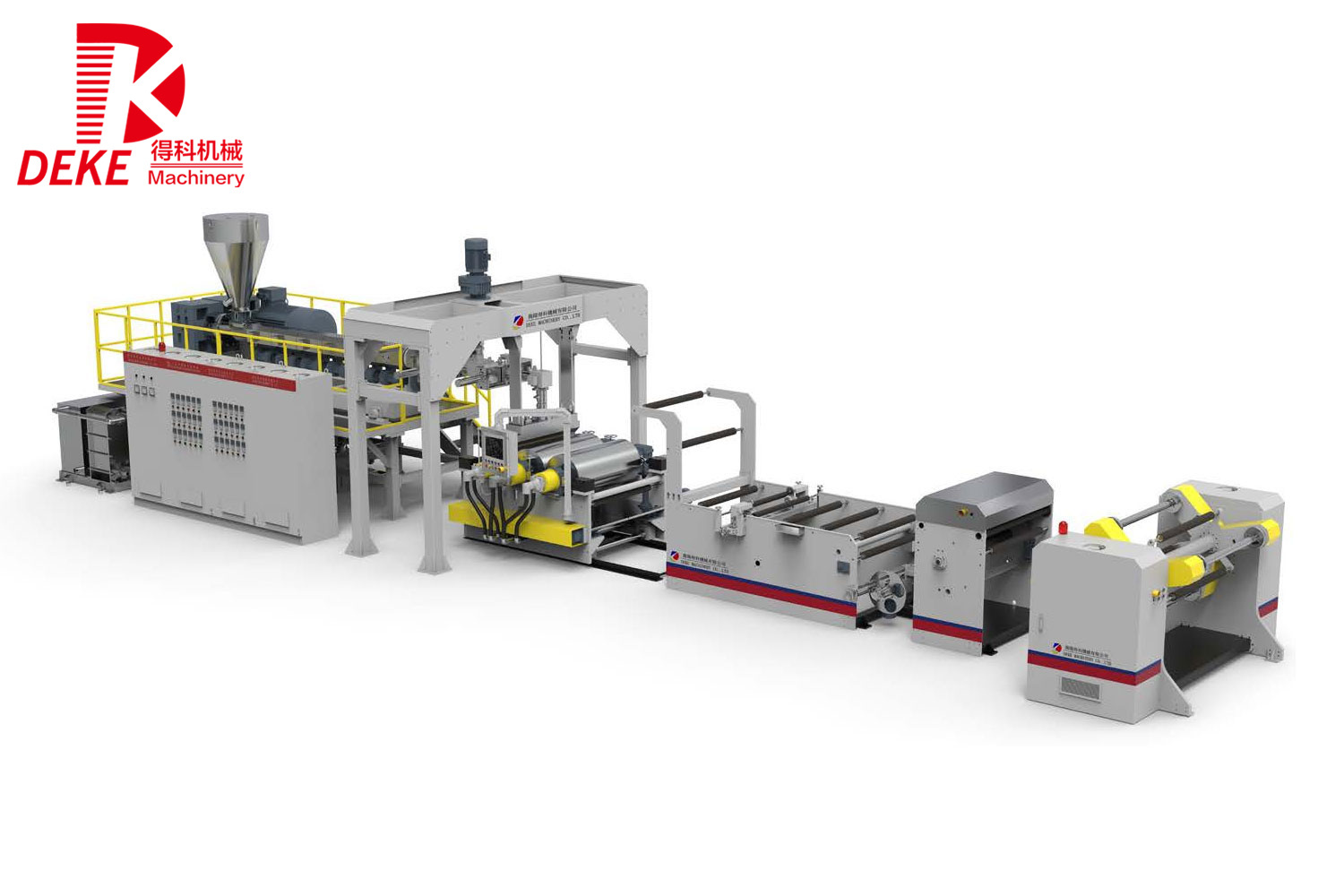

In addition to their mixing and temperature control features, small twin screw extruders are also known for their versatility in processing different product shapes and sizes. They can be employed in the production of various end products, ranging from pellets and granules to films and fibers. This adaptability makes them a popular choice in industries such as packaging, automotive, and consumer goods.

Furthermore, the compact design of small twin screw extruders offers space-saving advantages, making them suitable for smaller production facilities or labs. Their modularity allows for easy integration into existing production lines, enhancing overall productivity without requiring significant investments in floor space.

The control systems used in modern small twin screw extruders also contribute to their effectiveness. Advanced automation and monitoring systems allow operators to precisely adjust process parameters, leading to enhanced repeatability and consistency in production. This level of control is particularly important in research and development settings where achieving specific material properties is essential.

In conclusion, small twin screw extruders play a pivotal role in the plastic processing industry due to their superior mixing capabilities, temperature control, versatility, and compact design. By understanding the benefits and applications of these machines, manufacturers can leverage their capabilities to enhance product quality and operational efficiency. Whether for small-scale production or laboratory use, small twin screw extruders offer a reliable solution for various plastic processing needs.

RELATED INFORMATION

Understanding PET Sheet Extruder Machines: A Comprehensive Guide

PET sheet extruder machines are specialized equipment used in the plastic processing industry to produce sheets made from polyethylene terephthalate (PET). These machines play a crucial role in various applications, including packaging, automotive parts, and consumer goods. Understanding how these machines work, their components, and their applications can help manufacturers improve efficiency and

Exploring the Efficiency of PET Single Screw Extruders in Manufacturing

Exploring the Efficiency of PET Single Screw Extruders in Manufacturing Table of Contents 1. Introduction to PET Single Screw Extruders 2. The Importance of PET in the Manufacturing Process 3. Design and Mechanism of Single Screw Extruders 4. Efficiency Factors of PET Single Screw Extruders 5. Applications of PET Single Screw Extruders in Manufacturing 6. Maintenance and O