2025/01

Maximizing Output with Twin Screw Roller Head Extruder Settings: A Comprehensive Guide

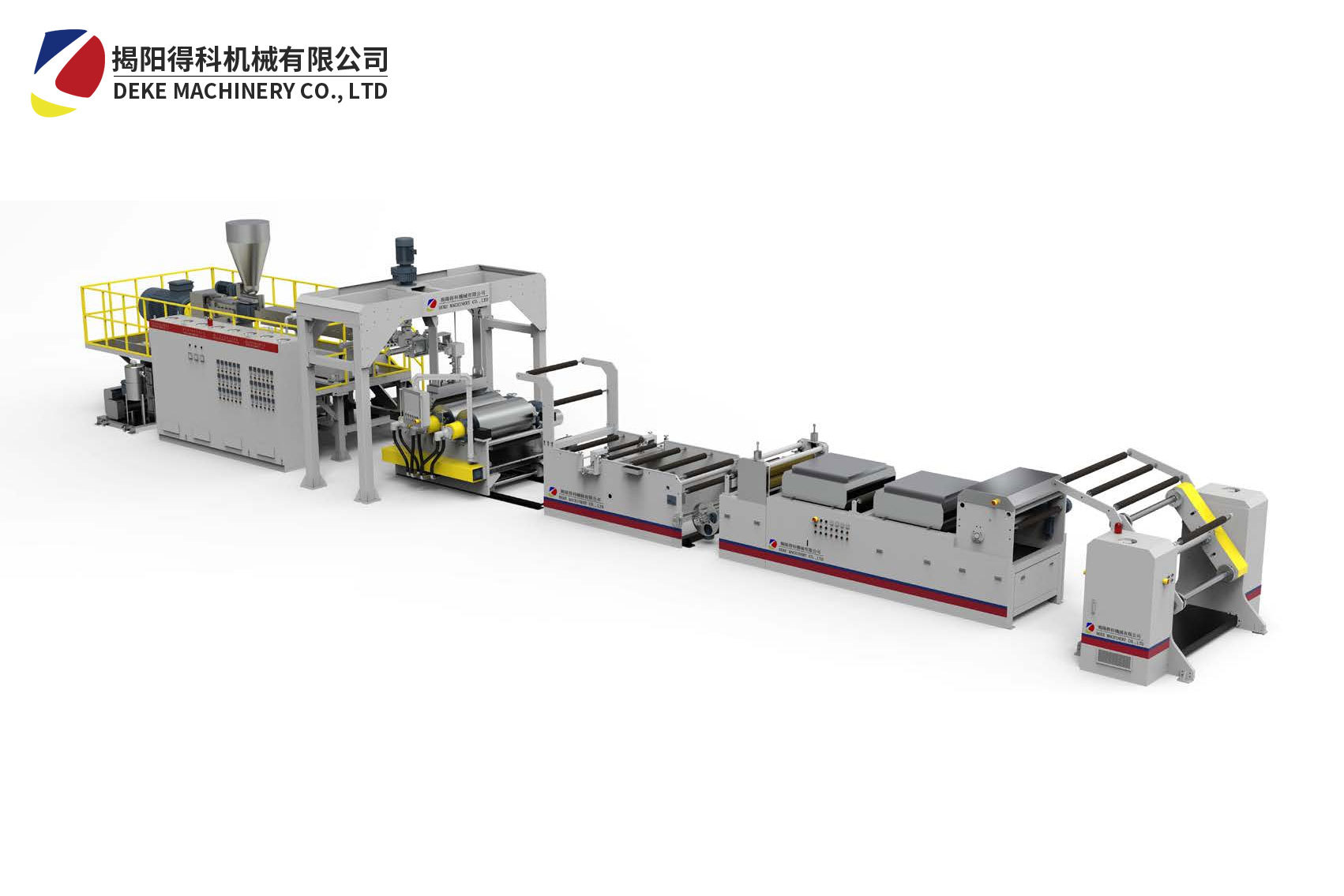

Maximizing Output with Twin Screw Roller Head Extruder Settings Introduction to Twin Screw Roller Head Extruders In the world of plastic processing machinery, **twin screw roller head extruders** stand out for their versatility and efficiency. These machines are designed to handle various materials, making them indispensable in the manufacturing sector. Understanding how to optimize their settings

2025/01

Understanding the Benefits and Functionality of Parallel Twin Screw Extruders

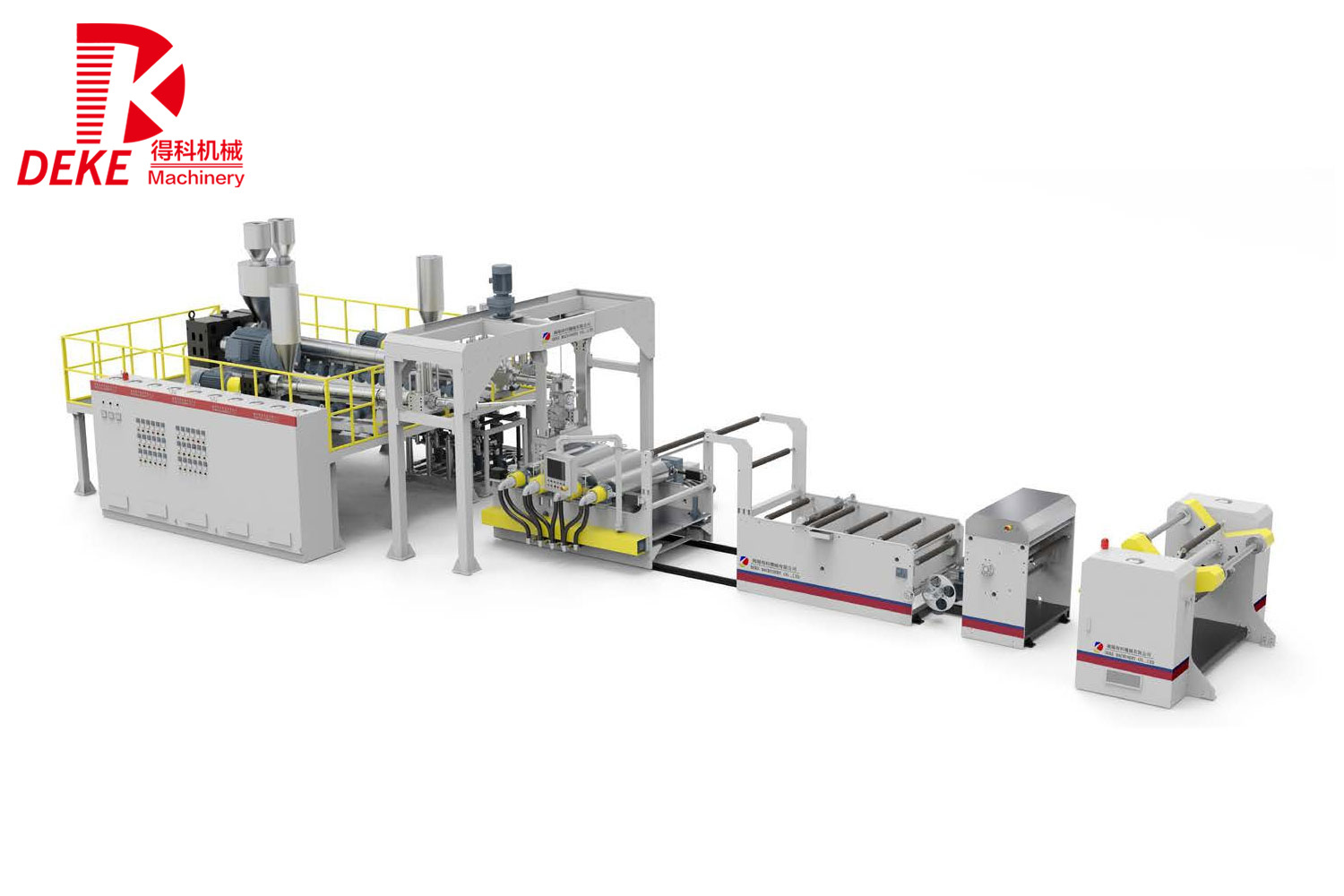

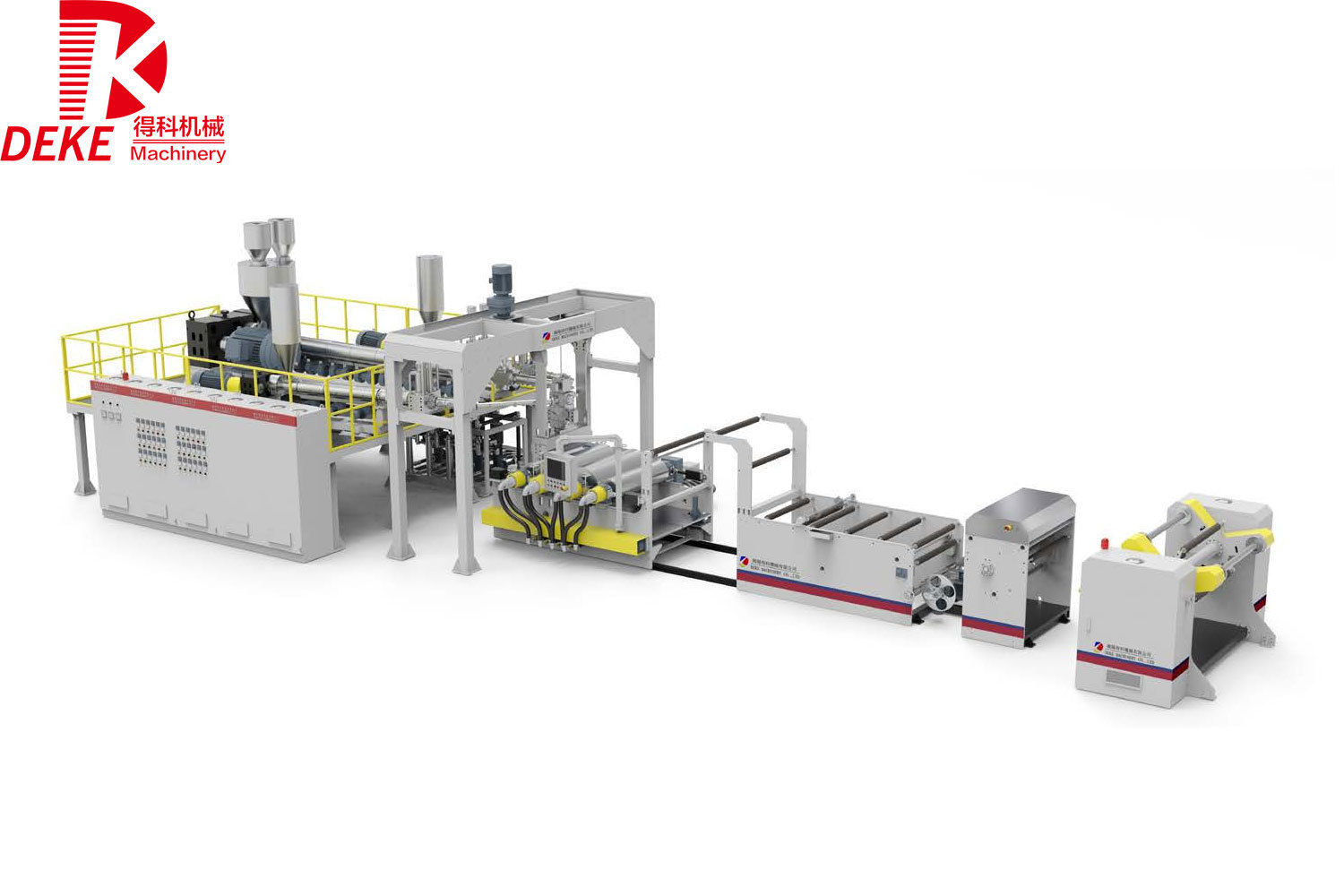

Parallel twin screw extruders are specialized machines widely used in the plastic processing industry. As the name suggests, these extruders feature two parallel screws that rotate synchronously within a barrel, providing a unique method of material handling and processing. This design allows for enhanced mixing, compounding, and extrusion of a variety of materials, making them an essential tool f

2025/01

Exploring the Mechanisms Behind Parallel Twin Screw Extruders: A Comprehensive Guide

Exploring the Mechanisms Behind Parallel Twin Screw Extruders Table of Contents Introduction to Parallel Twin Screw Extruders Understanding the Structure of Parallel Twin Screw Extruders Mechanical Principles of Extrusion Advantages of Parallel Twin Screw Extruders Applications in the Plastic Processing Industry Common Challenges and Solutions Maintenance and Optimizat

2025/01

The Versatility and Efficiency of Parallel Twin Screw Extruders in Plastic Processing

Parallel twin screw extruders are a vital component in the field of plastic processing machinery, particularly in the manufacturing of various plastic products. These sophisticated machines consist of two parallel screws that rotate synchronously within a heated barrel. The design and operation of parallel twin screw extruders offer numerous benefits, making them a preferred choice for many applic

2025/01

Unlocking Efficiency: The Comprehensive Benefits of Using a Parallel Twin Screw Extruder

Unlocking Efficiency: The Comprehensive Benefits of Using a Parallel Twin Screw Extruder Table of Contents 1. Introduction to Parallel Twin Screw Extruders 2. What is a Parallel Twin Screw Extruder? 3. Key Features of Parallel Twin Screw Extruders 3.1. Unique Design and Configuration 3.2. Versatile Processing Capabilities 4. Benefits of Using Parallel Twin Screw Extruders 4.1. Enhanced Efficiency

2025/01

Exploring the Advantages of EVOH High Barrier Sheet Extruders in Plastic Processing

EVOH (Ethylene Vinyl Alcohol) high barrier sheet extruders are an integral part of the plastic processing machinery landscape, particularly in applications that require superior barrier properties. These extruders are designed to produce sheets made from EVOH, a material known for its excellent gas barrier capabilities, which makes it highly desirable in food packaging, pharmaceuticals, and other

2025/01

Why Choose an EVOH High Barrier Sheet Extruder for Your Production Needs

Why Choose an EVOH High Barrier Sheet Extruder for Your Production Needs Table of Contents 1. Introduction to EVOH High Barrier Sheet Extruders 2. Understanding EVOH Material Properties 3. Advantages of EVOH High Barrier Sheet Extruders 3.1 Product Safety and Preservation 3.2 Cost Efficiency in Production 4. Application

2025/01

Understanding the Importance of EVOH High Barrier Sheet Extruders in Plastic Processing

EVOH (Ethylene Vinyl Alcohol) high barrier sheet extruders are essential in the manufacturing and processing of plastic films and sheets that require superior barrier properties. These extruders specialize in producing sheets that are particularly resistant to gases and moisture, making them ideal for a variety of applications, including food packaging, pharmaceuticals, and other sensitive product

2024/12

Unveiling the Critical Role of EVOH in High Barrier Sheet Extrusion Table of Contents 1. Introduction to High Barrier Sheet Extrusion 2. What is EVOH? 3. Properties of EVOH: Why It Matters 4. Applications of EVOH in Packaging 5. Advantages of Using EVOH in High Barrier Sheets 6. The Sustainability Aspect of EVOH 7. EVOH in the Manufacturing Process of Extrusion 8.

2024/09

Advantages of biodegradable extruder

The advantages of biodegradable extruders are mainly reflected in environmental protection, high-efficiency output, precise control, customized functions, easy operation and intelligent control.

RELATED INFORMATION

Maximizing Output with Twin Screw Roller Head Extruder Settings: A Comprehensive Guide

Maximizing Output with Twin Screw Roller Head Extruder Settings Introduction to Twin Screw Roller Head Extruders In the world of plastic processing machinery, **twin screw roller head extruders** stand out for their versatility and efficiency. These machines are designed to handle various materials, making them indispensable in the manufacturing sector. Understanding how to optimize their settings

Understanding the Benefits and Functionality of Parallel Twin Screw Extruders

Parallel twin screw extruders are specialized machines widely used in the plastic processing industry. As the name suggests, these extruders feature two parallel screws that rotate synchronously within a barrel, providing a unique method of material handling and processing. This design allows for enhanced mixing, compounding, and extrusion of a variety of materials, making them an essential tool f