Why Choose an EVOH High Barrier Sheet Extruder for Your Production Needs

2025-01

Why Choose an EVOH High Barrier Sheet Extruder for Your Production Needs

Table of Contents

- 1. Introduction to EVOH High Barrier Sheet Extruders

- 2. Understanding EVOH Material Properties

- 3. Advantages of EVOH High Barrier Sheet Extruders

- 4. Applications of EVOH High Barrier Sheets

- 5. Choosing the Right EVOH High Barrier Sheet Extruder

- 6. Maintenance and Operational Tips for Optimal Performance

- 7. FAQs About EVOH High Barrier Sheet Extruders

- 8. Conclusion

1. Introduction to EVOH High Barrier Sheet Extruders

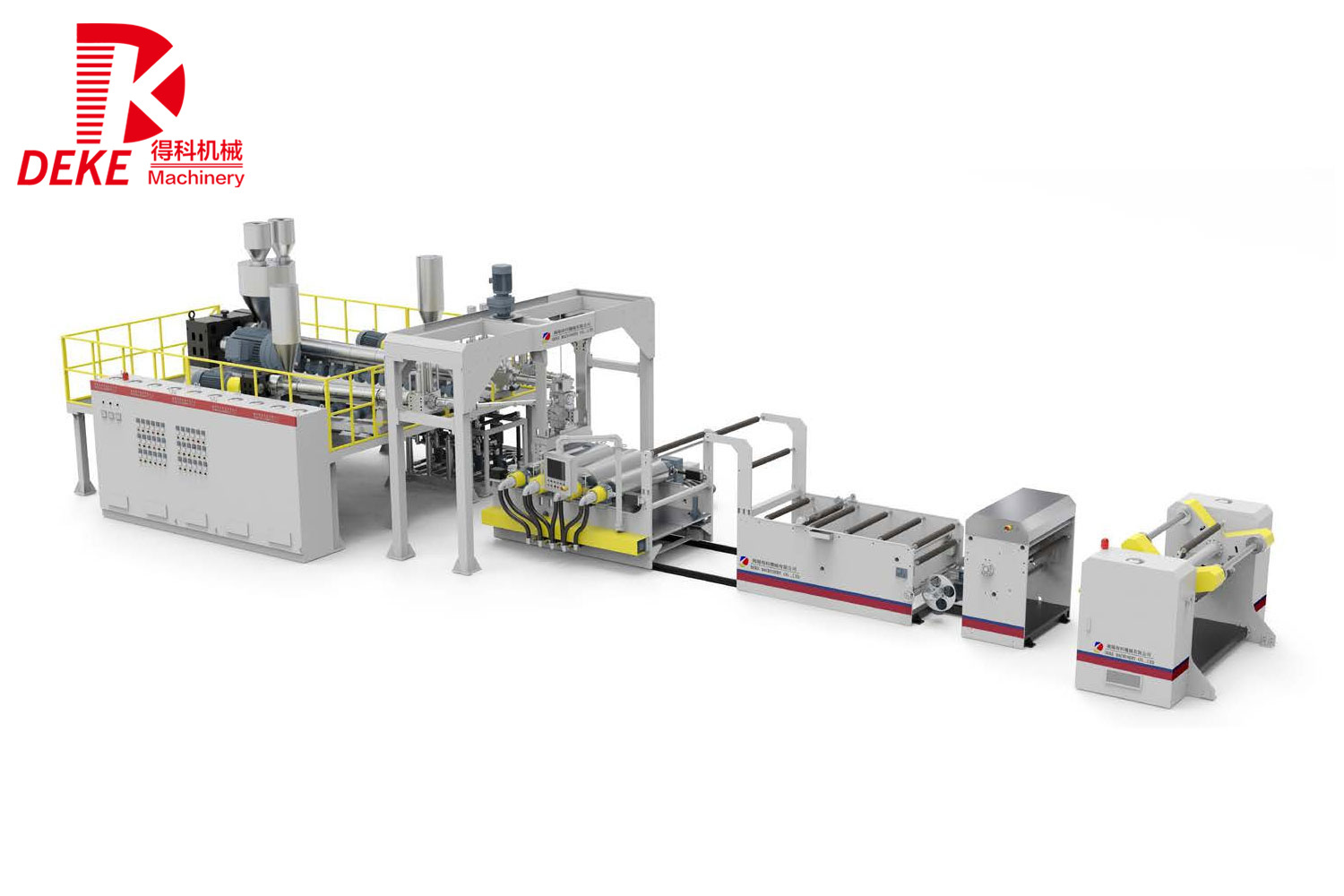

In the realm of manufacturing, selecting the right equipment is crucial for efficiency and product quality. **EVOH high barrier sheet extruders** stand out due to their unique ability to process ethylene vinyl alcohol (EVOH) materials, which provide exceptional barrier properties against gases and moisture. This article delves into the numerous benefits of opting for an EVOH high barrier sheet extruder, enabling you to meet the demands of various industries, from food packaging to medical supplies.

2. Understanding EVOH Material Properties

EVOH is a copolymer made from ethylene and vinyl alcohol, known for its superior barrier characteristics. It is especially effective at preventing oxygen ingress, which is essential in preserving the freshness and quality of food products. The material also boasts excellent chemical resistance and clarity, making it an attractive choice for various applications. Understanding these properties is critical for manufacturers looking to optimize their production processes and offer high-quality products.

2.1 Barrier Properties of EVOH

The primary advantage of EVOH lies in its **high barrier properties**. It is particularly effective in applications where oxygen-sensitive products are involved. For example, in food packaging, EVOH significantly extends shelf life by preventing oxidation. This property is crucial not only for food safety but also for maintaining flavor and nutritional value.

2.2 Processing Characteristics

EVOH can be processed using standard extrusion techniques, making it compatible with existing manufacturing setups. However, it requires precise temperature and moisture control during processing to achieve optimal results. Understanding these processing characteristics ensures manufacturers can effectively integrate EVOH sheet production into their operations.

3. Advantages of EVOH High Barrier Sheet Extruders

Investing in an EVOH high barrier sheet extruder offers numerous advantages that can significantly enhance your production capabilities.

3.1 Product Safety and Preservation

Safety is paramount in production, especially in the food and pharmaceutical industries. EVOH’s ability to keep out oxygen and moisture dramatically reduces the risk of spoilage and contamination. This leads to **increased product safety** and consumer trust. Moreover, using EVOH can help meet stringent regulatory standards, further enhancing your brand's reputation in the market.

3.2 Cost Efficiency in Production

While the initial investment in an EVOH high barrier sheet extruder may be higher than other options, the long-term benefits outweigh the costs. **Cost efficiency** is achieved through reduced packaging waste, lower product spoilage rates, and improved shelf life, leading to higher customer satisfaction and repeat business. Additionally, the durability of EVOH materials can minimize the need for frequent replacements, contributing to overall savings.

4. Applications of EVOH High Barrier Sheets

The versatility of EVOH high barrier sheets makes them suitable for various applications:

4.1 Food Packaging

In the food industry, EVOH is widely used for packaging perishable items, such as meats, cheeses, and snacks. The barrier properties extend shelf life while maintaining flavor and texture.

4.2 Medical Supplies

EVOH’s chemical resistance and barrier properties make it an ideal choice for packaging medical devices and pharmaceuticals, ensuring product integrity and safety.

4.3 Consumer Goods

Products such as cosmetics and household cleaners benefit from EVOH packaging, as it prevents leakage and contamination, enhancing consumer trust.

5. Choosing the Right EVOH High Barrier Sheet Extruder

Selecting the right extruder is a critical step in ensuring the success of your production line.

5.1 Key Features to Consider

When evaluating EVOH high barrier sheet extruders, consider the following key features:

- **Temperature Control**: Precise temperature regulation is vital for processing EVOH effectively.

- **Output Capacity**: Assess your production needs to select an extruder that meets your output requirements.

- **Ease of Maintenance**: Look for models that offer straightforward maintenance procedures to minimize downtime.

5.2 Brand Comparison and Market Options

Several reputable brands offer EVOH high barrier sheet extruders. A thorough comparison of specifications, customer reviews, and warranty offerings will help you identify the best options for your business. Engage with industry experts and seek recommendations based on real-world performance.

6. Maintenance and Operational Tips for Optimal Performance

To maximize the lifespan and efficiency of your EVOH high barrier sheet extruder, regular maintenance is essential. Here are some tips:

- **Regular Cleaning**: Keep the extruder clean to prevent material build-up, which can impair performance.

- **Monitor Temperature Settings**: Regularly check temperature settings to ensure they align with EVOH processing requirements.

- **Routine Inspections**: Conduct inspections to identify any wear and tear that could affect production.

7. FAQs About EVOH High Barrier Sheet Extruders

**Q1: What is an EVOH high barrier sheet extruder?**

An EVOH high barrier sheet extruder is a specialized machine designed to process ethylene vinyl alcohol materials, producing sheets with exceptional barrier properties against gases and moisture.

**Q2: What industries benefit from EVOH high barrier sheets?**

Industries such as food packaging, pharmaceuticals, cosmetics, and consumer goods benefit significantly from EVOH high barrier sheets due to their protective properties.

**Q3: How does EVOH compare to other barrier materials?**

Compared to other barrier materials, EVOH offers superior moisture and gas barrier properties, making it particularly effective for oxygen-sensitive products.

**Q4: Is it challenging to process EVOH?**

While EVOH requires careful temperature and moisture control during processing, it is compatible with standard extrusion techniques, making it relatively easy to integrate into existing setups.

**Q5: What are the long-term benefits of using an EVOH high barrier sheet extruder?**

Long-term benefits include extended product shelf life, reduced spoilage, improved product safety, and overall cost efficiency in production.

8. Conclusion

Choosing an **EVOH high barrier sheet extruder** for your production needs can significantly enhance your operations, offering unparalleled product safety, cost efficiency, and versatility across various applications. Understanding the properties of EVOH and the advantages of dedicated extruders allows you to make informed decisions that align with your production goals. By investing in this technology, you not only improve your product quality but also position your brand for long-term success in a competitive market.

RELATED INFORMATION

Understanding the Benefits and Functionality of Parallel Twin Screw Extruders

Parallel twin screw extruders are specialized machines widely used in the plastic processing industry. As the name suggests, these extruders feature two parallel screws that rotate synchronously within a barrel, providing a unique method of material handling and processing. This design allows for enhanced mixing, compounding, and extrusion of a variety of materials, making them an essential tool f

Exploring the Mechanisms Behind Parallel Twin Screw Extruders: A Comprehensive Guide

Exploring the Mechanisms Behind Parallel Twin Screw Extruders Table of Contents Introduction to Parallel Twin Screw Extruders Understanding the Structure of Parallel Twin Screw Extruders Mechanical Principles of Extrusion Advantages of Parallel Twin Screw Extruders Applications in the Plastic Processing Industry Common Challenges and Solutions Maintenance and Optimizat