Exploring the Advantages of EVOH High Barrier Sheet Extruders in Plastic Processing

2025-01

One of the primary advantages of using EVOH in sheet extrusion is its ability to effectively block oxygen transmission. This property is crucial for extending the shelf life of food products and protecting sensitive goods from degradation. When oxygen permeates packaging, it can lead to spoilage or loss of flavor, making EVOH a top choice for manufacturers aiming to enhance their product preservation.

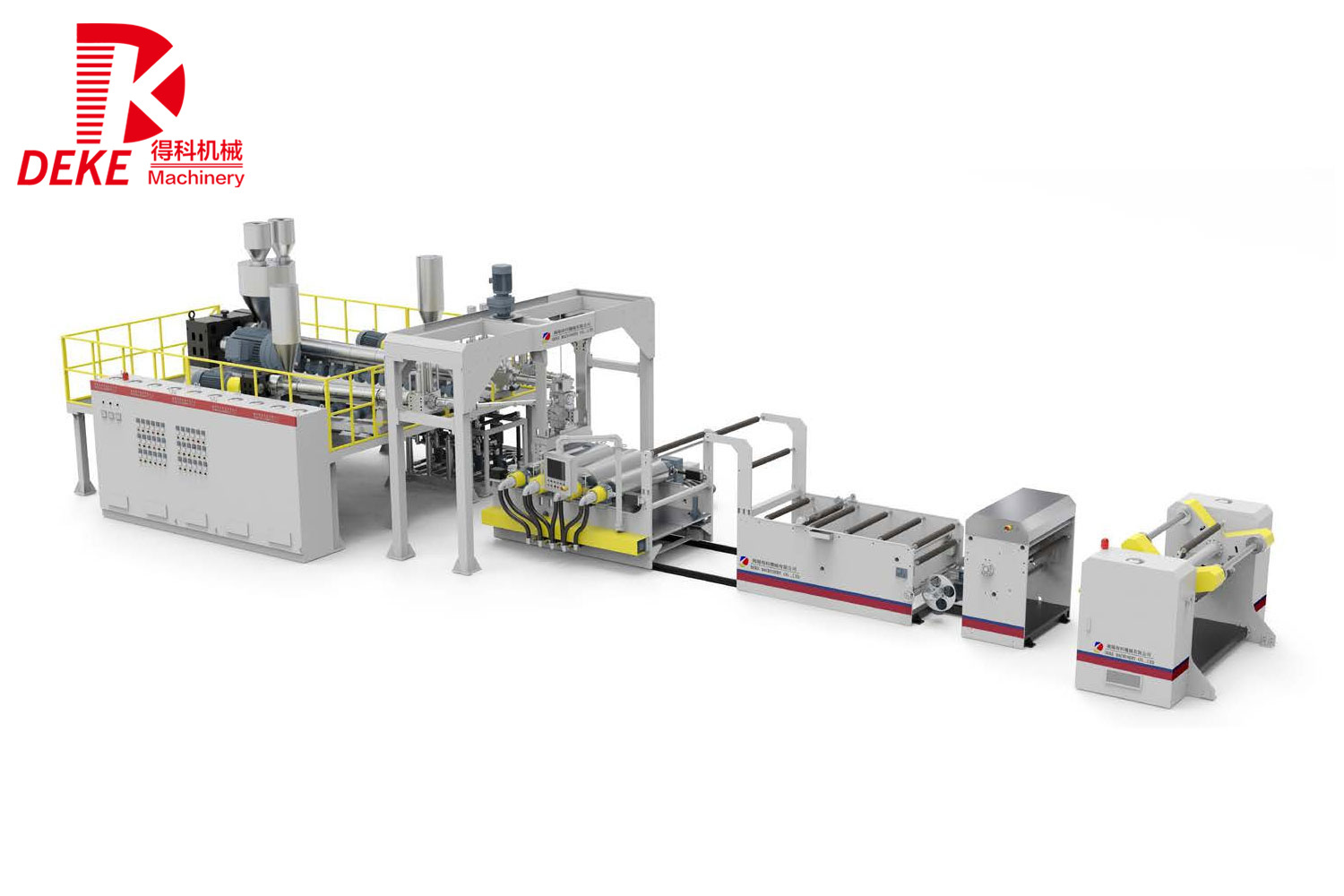

The process of extruding EVOH sheets involves several steps, starting with the melting of polymer pellets, which are then forced through a die to form sheets of desired thickness. Advanced extruder designs, equipped with precise temperature and pressure controls, enable consistent production quality and efficiency. Furthermore, the incorporation of cooling systems ensures that the sheets maintain their structural integrity during the cooling phase.

In addition to their barrier properties, EVOH sheets are also versatile in terms of compatibility with other materials. They can be easily co-extruded with PE (Polyethylene) or PP (Polypropylene), creating multi-layer films that combine strength, flexibility, and barrier properties. This versatility allows manufacturers to tailor their packaging solutions according to specific needs, enhancing product appeal and functionality.

Moreover, the use of EVOH high barrier sheets can contribute to sustainability efforts. With their ability to prolong product life, companies can reduce food waste and minimize their environmental footprint. By investing in high-quality EVOH extruders, manufacturers are not only improving their product offerings but are also aligning with global sustainability trends.

In conclusion, EVOH high barrier sheet extruders represent a significant technological advancement in the plastic processing industry. Their unique properties and capabilities make them a valuable asset for manufacturers looking to improve product longevity and quality. As the demand for better packaging solutions continues to rise, understanding the role of EVOH in extrusion processes will be essential for professionals in the field. Embracing this technology will not only enhance competitive advantage but also pave the way for innovative packaging solutions that meet the evolving needs of consumers.

Previous Page:

RELATED INFORMATION

Understanding the Benefits and Functionality of Parallel Twin Screw Extruders

Parallel twin screw extruders are specialized machines widely used in the plastic processing industry. As the name suggests, these extruders feature two parallel screws that rotate synchronously within a barrel, providing a unique method of material handling and processing. This design allows for enhanced mixing, compounding, and extrusion of a variety of materials, making them an essential tool f

Exploring the Mechanisms Behind Parallel Twin Screw Extruders: A Comprehensive Guide

Exploring the Mechanisms Behind Parallel Twin Screw Extruders Table of Contents Introduction to Parallel Twin Screw Extruders Understanding the Structure of Parallel Twin Screw Extruders Mechanical Principles of Extrusion Advantages of Parallel Twin Screw Extruders Applications in the Plastic Processing Industry Common Challenges and Solutions Maintenance and Optimizat