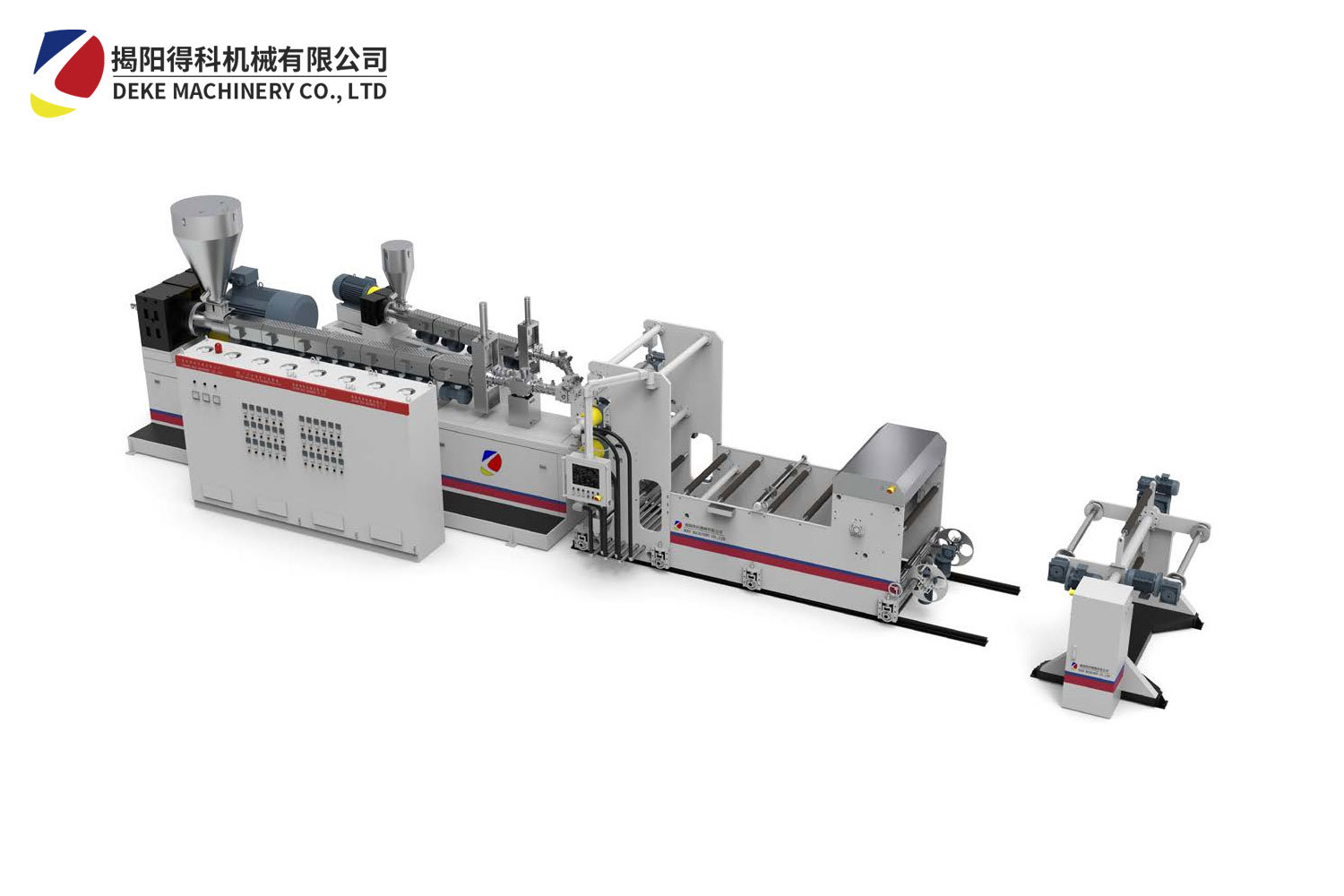

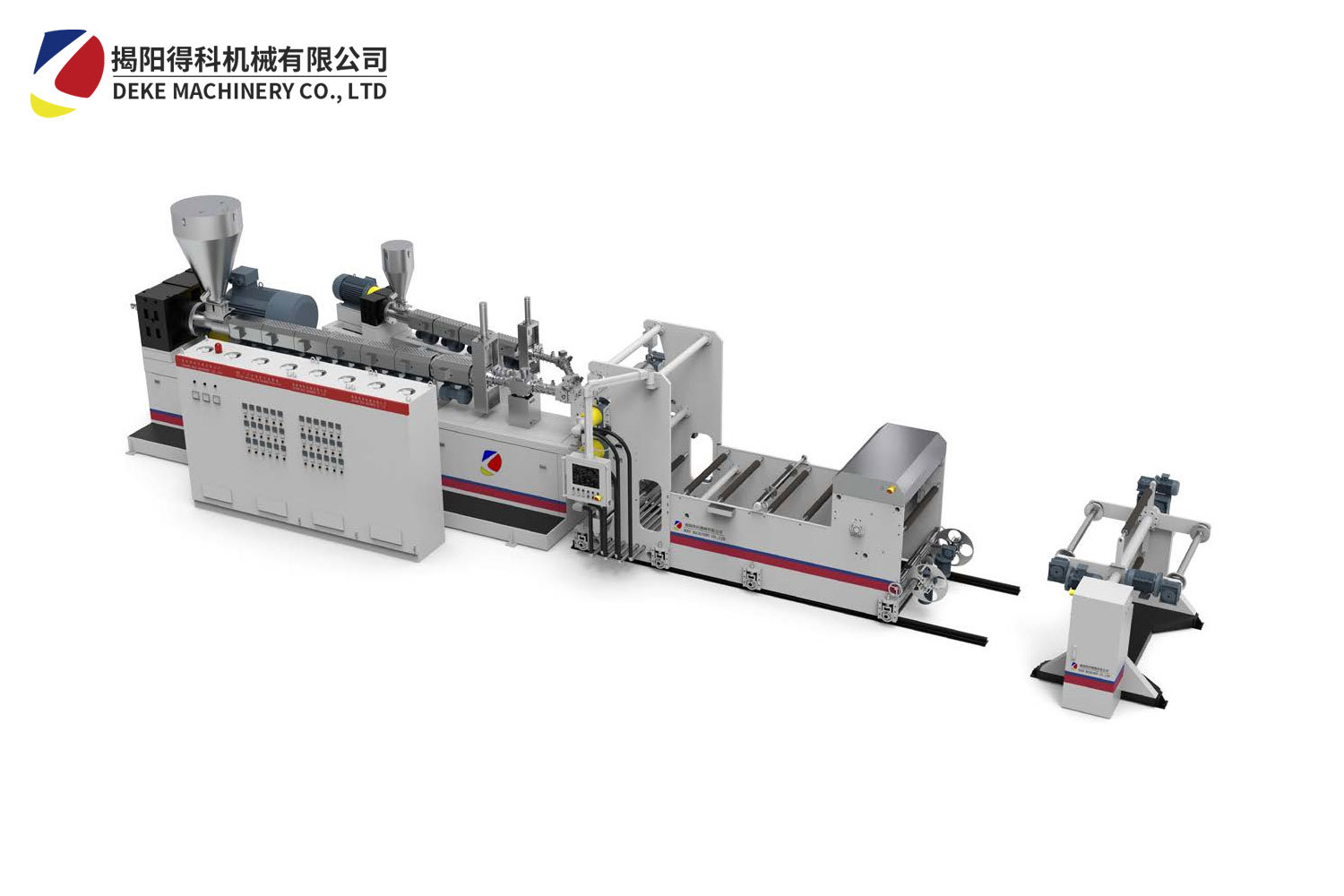

Twin screw co rotating extruder

2025-04

The twin screw co rotating extruder is a high-performance equipment widely used in many fields such as plastic processing.

From the structural characteristics, the twin screw co rotating extruder has two screws rotating in the same direction. The two screws cooperate with each other and play a unique role in the material transmission process. The screw fins are precisely designed to efficiently shear, mix, knead and other operations on the material. This twin screw structure can provide a strong conveying capacity, ensure that the material moves forward steadily in the barrel, avoid stagnation and blockage of the material, and make the entire extrusion process continuous and stable.

In terms of material processing, the twin screw co rotating extruder has an excellent mixing effect. For materials with multiple components, such as resins, additives, fillers, etc. in plastics, they can be mixed evenly. Whether it is mixing and toning plastic particles of different colors or adding various functional additives (such as flame retardants, antioxidants, etc.) to the plastic matrix, a highly uniform mixing state can be achieved. At the same time, it can also effectively plasticize the material to achieve an ideal molten state, which is essential for the production of high-quality plastic products.

In terms of application areas, the twin screw co rotating extruder has a wide range of applications. In the field of plastic modification, it can produce a variety of high-performance modified plastics; in the preparation of polymer composite materials, it can ensure the good compounding of materials in different phases; in the production process of hot melt adhesives, masterbatches, etc., it can also play an excellent mixing and extrusion ability, providing high-quality material processing solutions for many industries, helping to improve product quality and production efficiency.

RELATED INFORMATION

Understanding the Benefits and Applications of Parallel Twin Screw Extruders

In the realm of plastic processing machinery, the parallel twin screw extruder stands out as a versatile and effective solution for a variety of applications. This type of extruder is characterized by two screws that run parallel to each other, allowing for efficient melting, mixing, and compounding of materials. The design of the parallel twin screw extruder enables a uniform and consistent outpu

Innovative Applications of Parallel Twin Screw Extruder Technology in Modern Manufacturing

Innovative Applications of Parallel Twin Screw Extruder Technology Introduction to Parallel Twin Screw Extruders The **parallel twin screw extruder** has emerged as a pivotal technology in the realm of manufacturing, particularly within the plastic processing sector. Characterized by two intermeshing screws rotating in the same direction, these extruders are designed to efficiently mix, melt, and