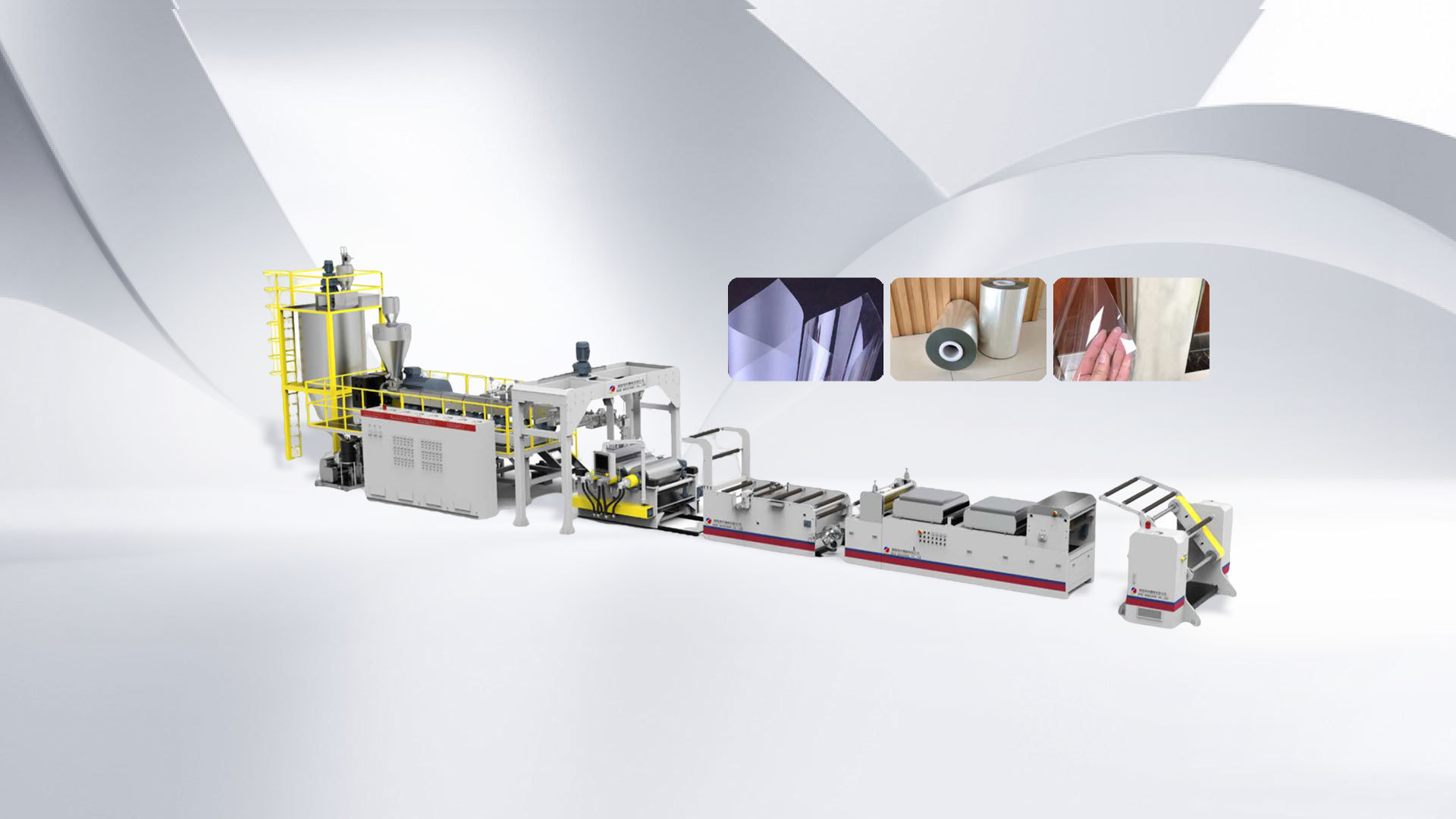

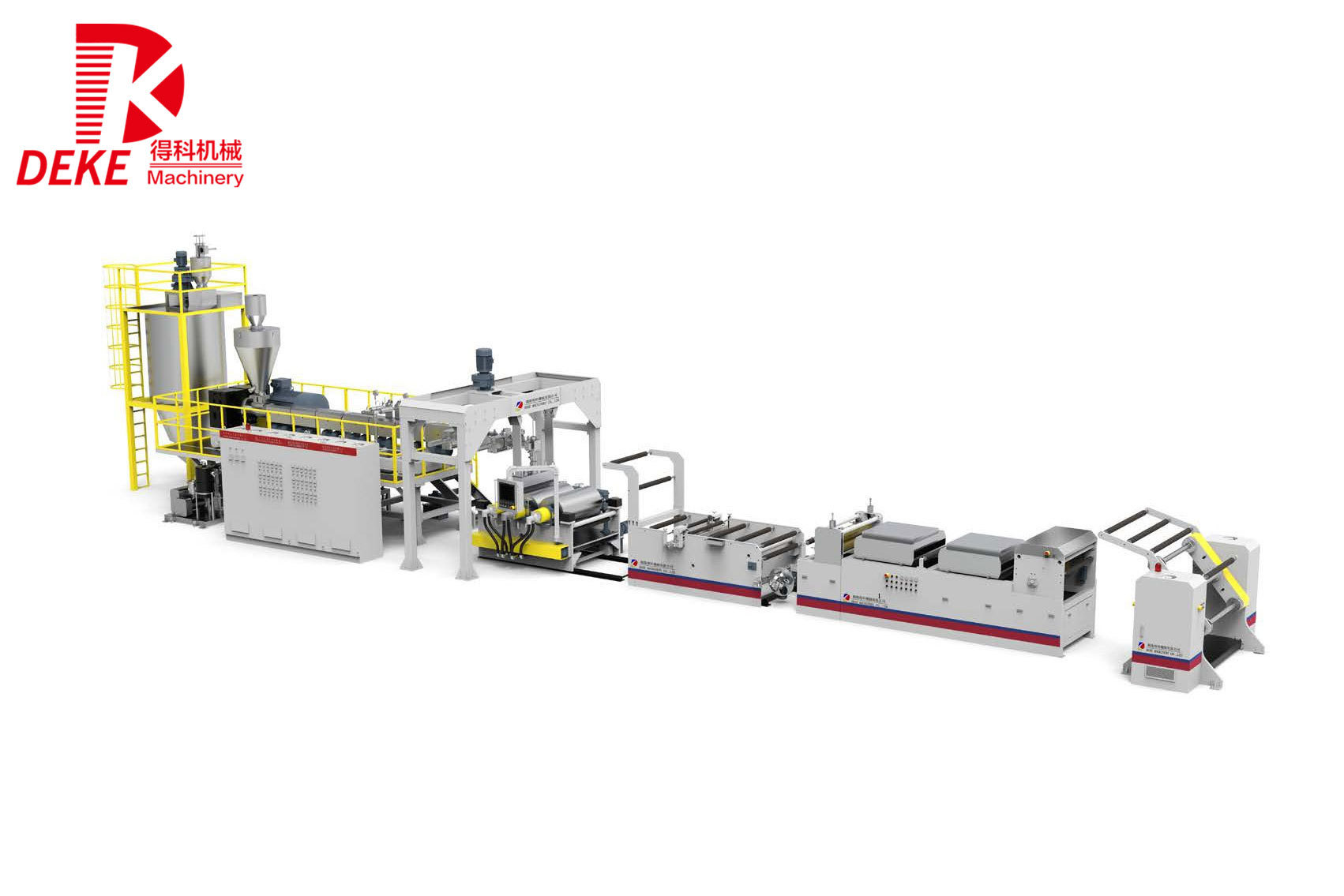

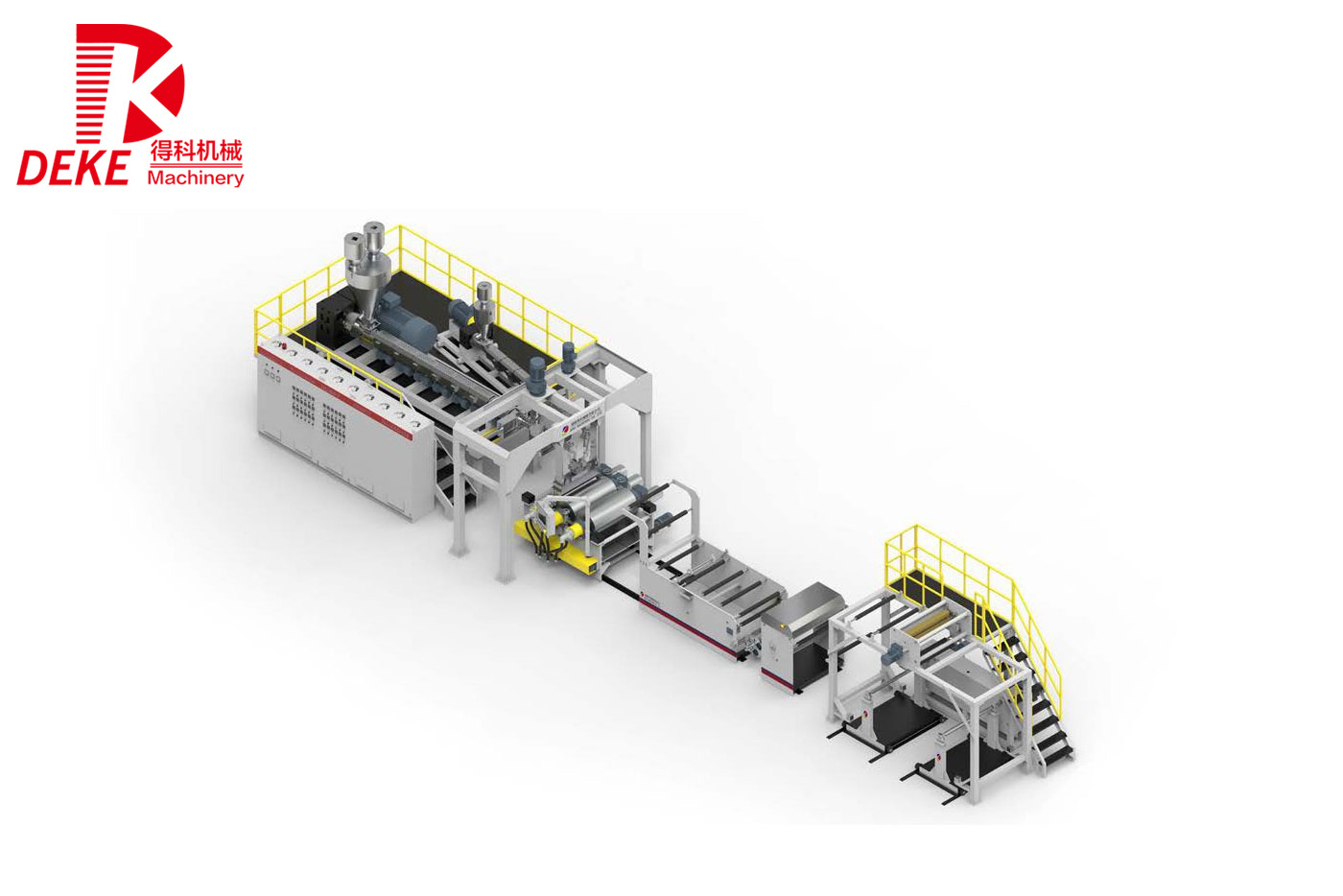

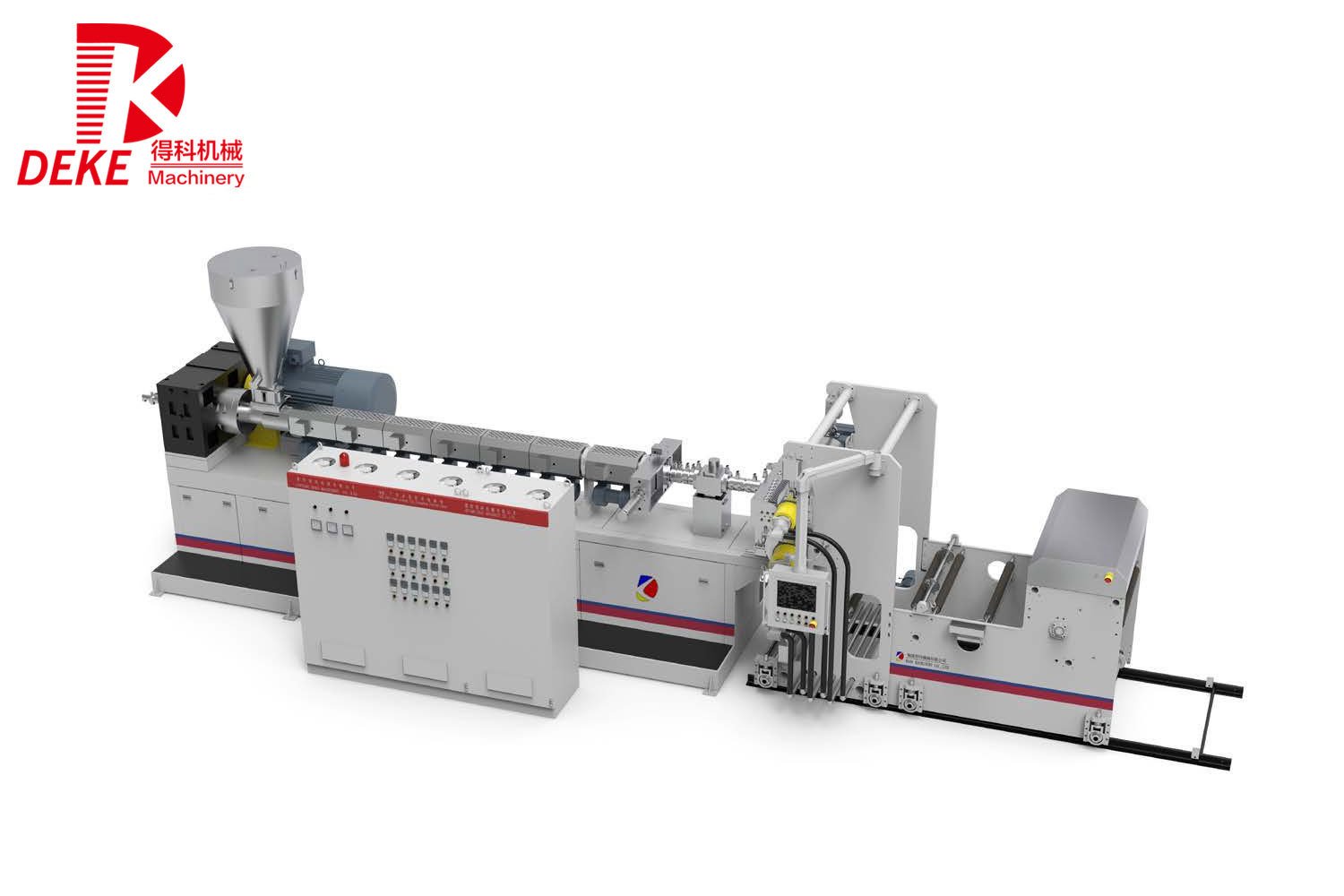

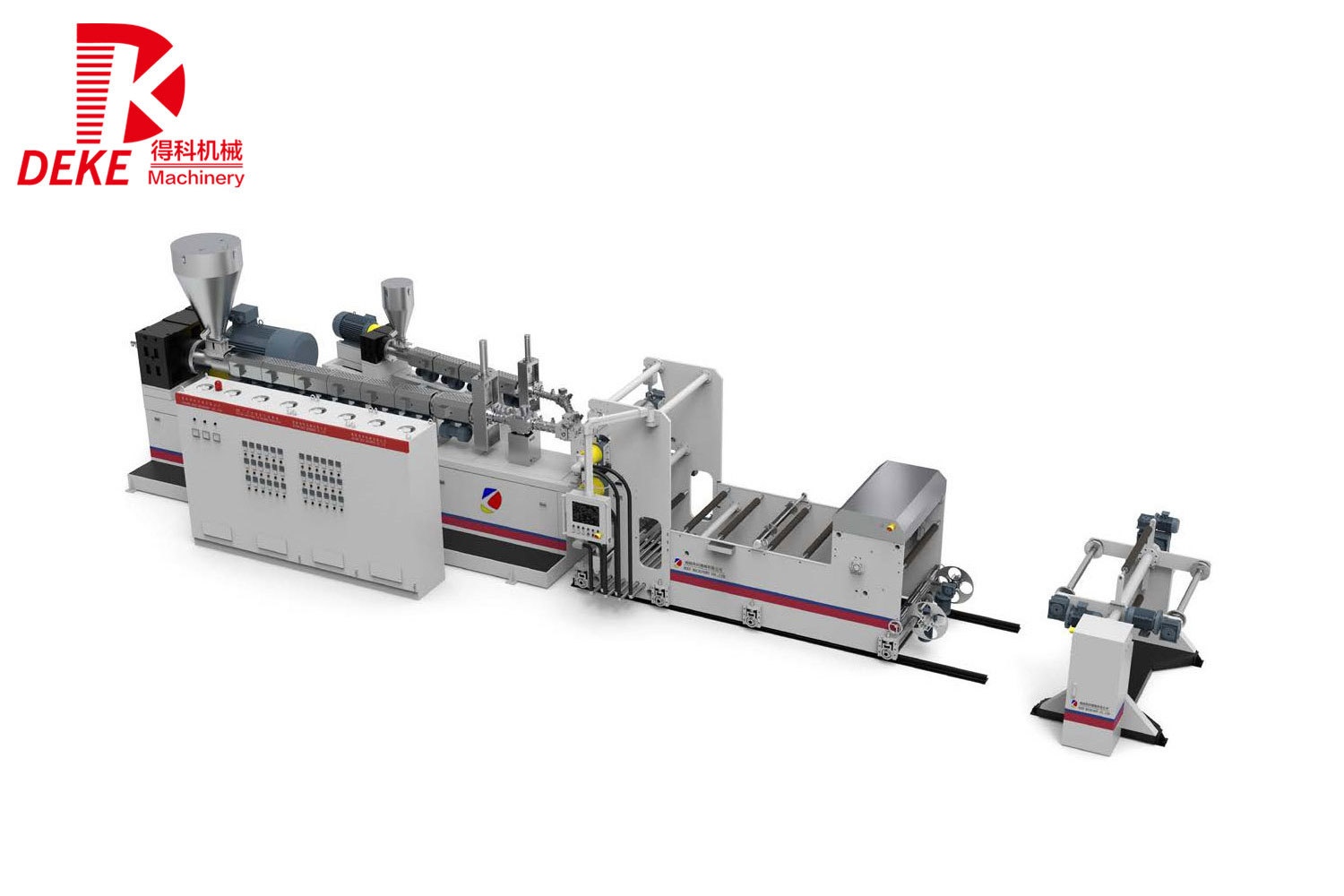

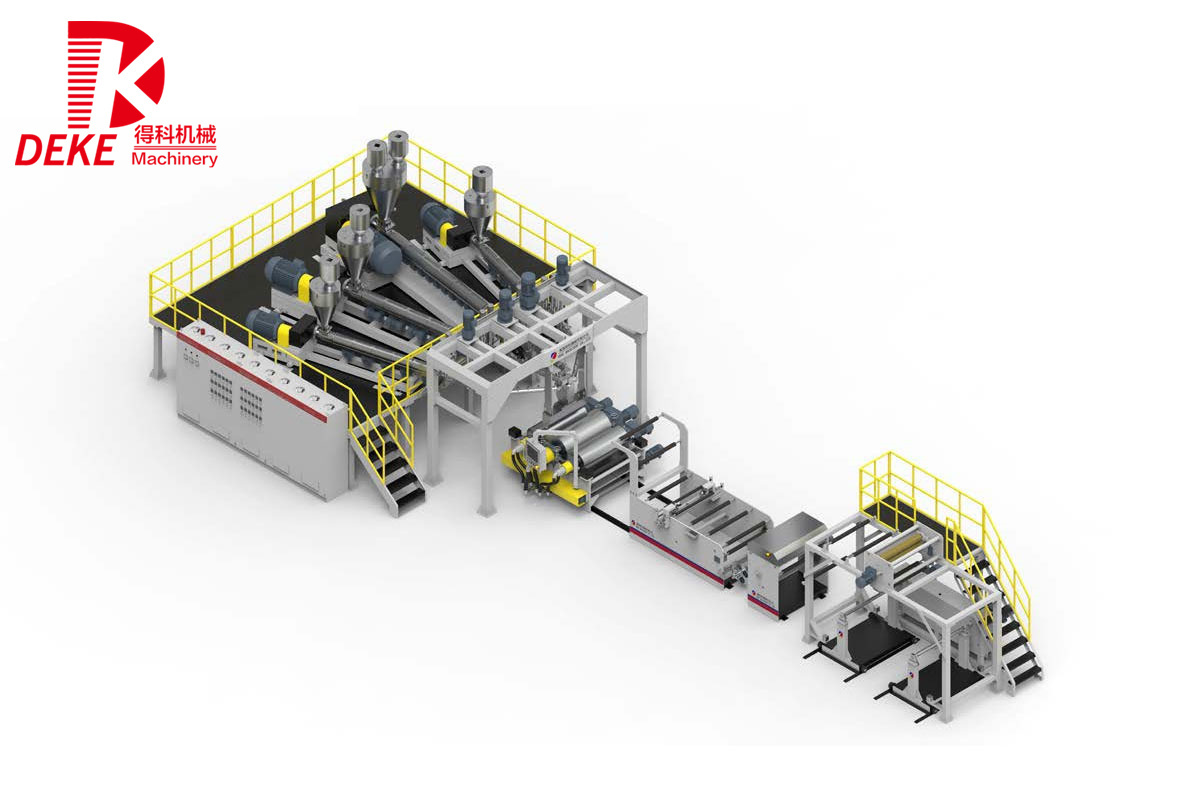

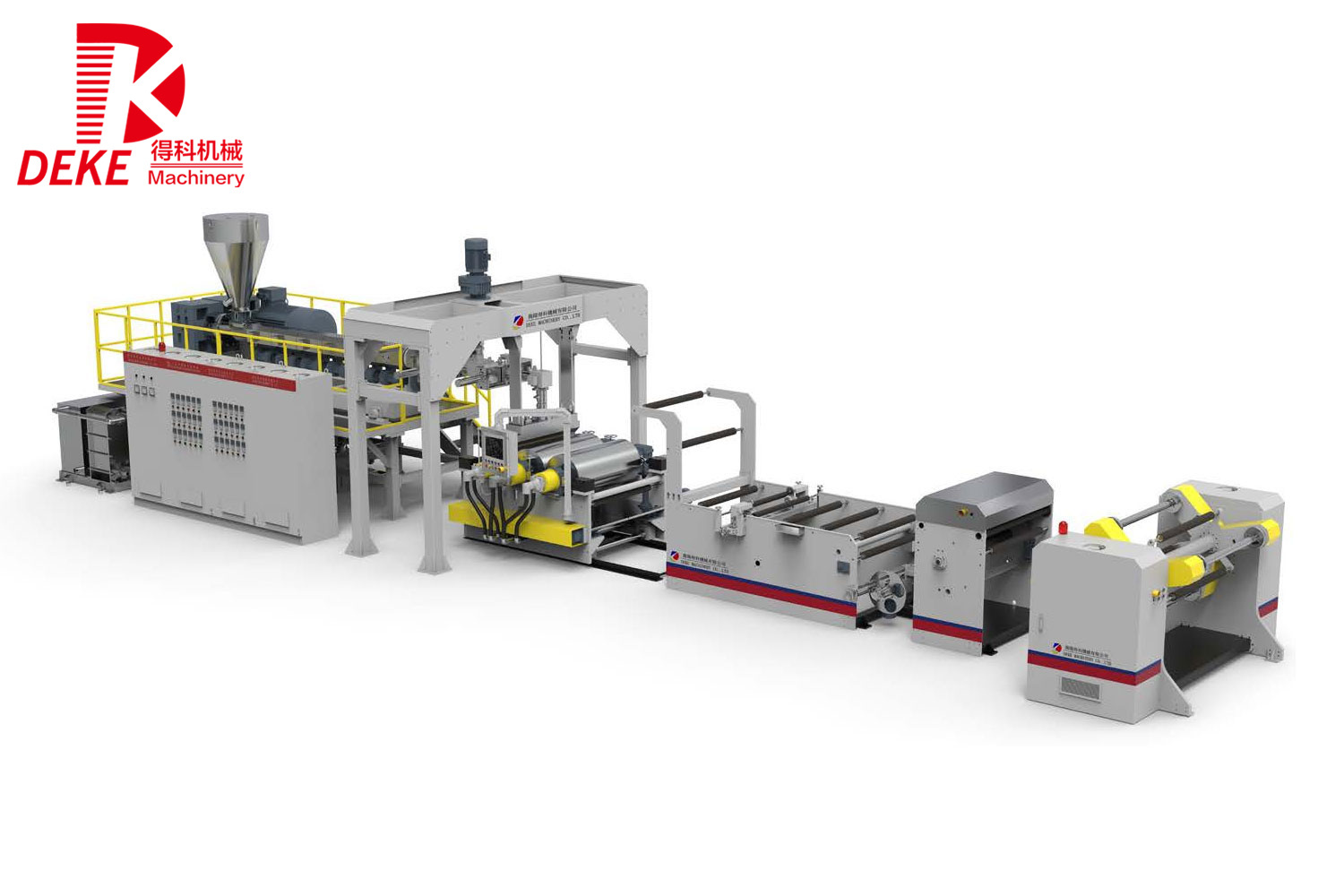

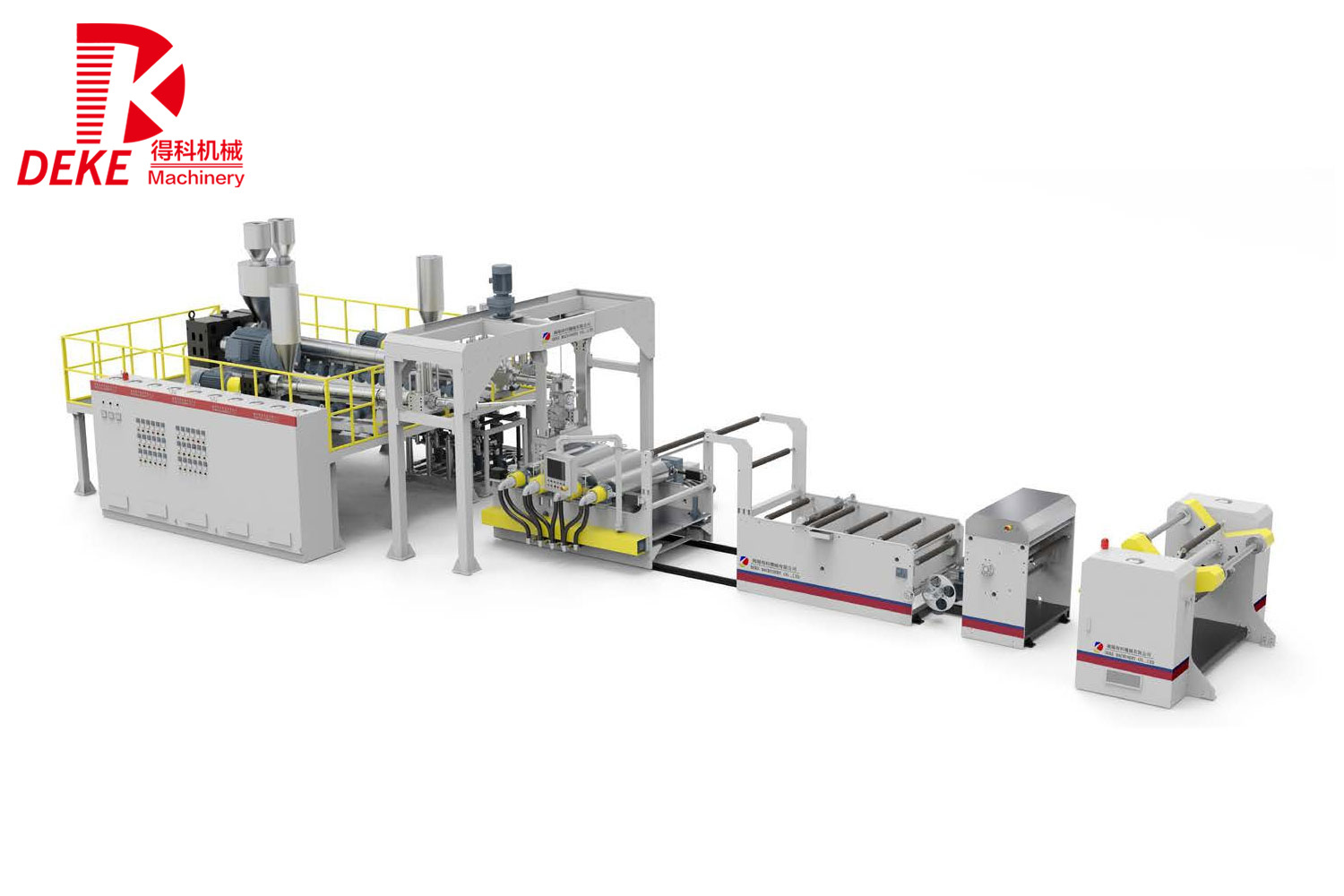

PRODUCTS

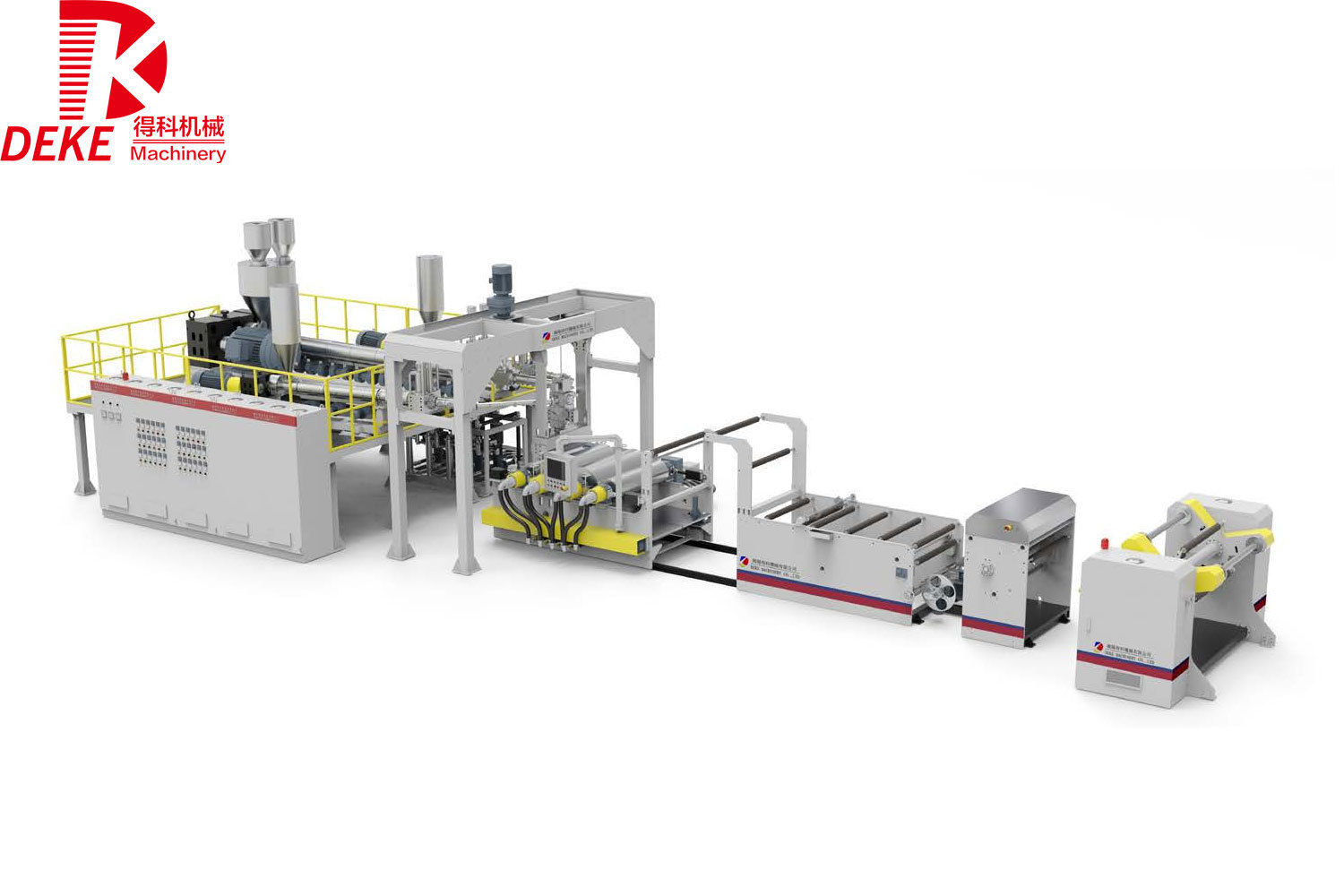

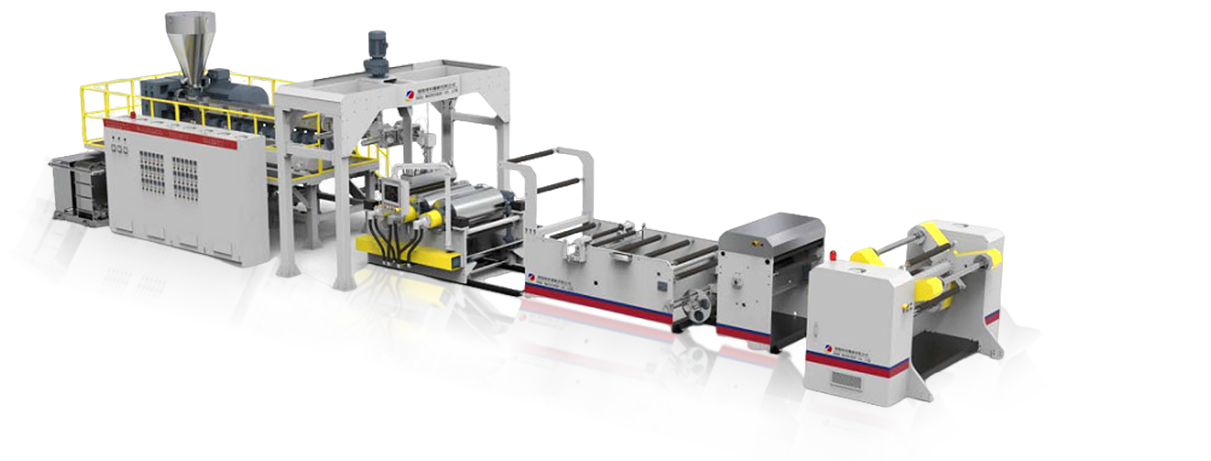

Our products have many mechanical models and complete specifications, which can meet the needs of different users.

ABOUT DEKE

It's a delight to have friends coming from afar! Jieyang Deke Machinery Co., Ltd. sincerely welcomes friends from the industry to visit our company for guidance!

DEKE Machinery (DEKE Machinery) is located in Jieyang City, Guangdong Province, the town of industrial zone, and Shantou City, bordering. Adjacent to Jieyang Chaoshan International Airport and Xiamen-Shenzhen Railway Chaoshan Station, convenient transportation.

The company specializes in the research and development, production, sales and after-sales service of plastic sheet extruder. The company serves customers with technology-driven service. It has a technical team with many years of experience and strong strength. At present, the company specializes in the production of PP,PS,PET,PC,ABS,PLA,EVOH and other single/multi-layer plastic sheet extrusion equipment. The quality and performance are at the domestic high-quality level!

Company established in 2019

Floor Area

Exporting Countries

Online Consulting

Need help finding the right solution together with our experts?

Contact to negotiate

OUR ADVANTAGES

The company has successfully developed a number of new patents and has a perfect product quality assurance system.

DEKE BLOGS

Keep abreast of relevant information of Deke Machinery Company