Common maintenance methods for extruders

2024-09

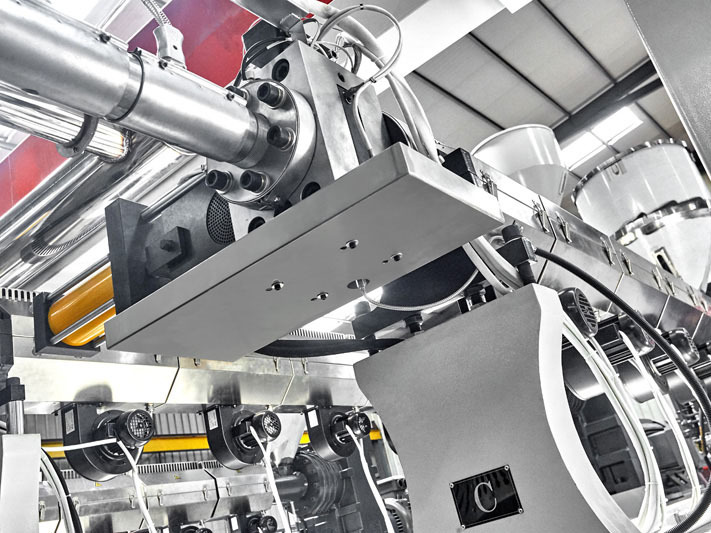

Extruder is a commonly used plastic processing equipment. Regular maintenance can extend the service life of the equipment, improve production efficiency and reduce the occurrence of failures. The following is the maintenance method of extruder:

1. Cleaning equipment: Clean the internal and external surfaces of the extruder regularly to remove dust, residue and oil. When cleaning, pay attention to the use of appropriate cleaning agents to avoid damage to the equipment.

2. Lubrication equipment: Regularly lubricate each lubrication part of the extruder, use an appropriate amount of lubricating oil to maintain the normal operation of the equipment. In particular, the sliding parts and transmission parts of the extruder need to be lubricated and inspected regularly.

3. Check the electrical system: regularly check the electrical system of the extruder, including power wiring, cables, switches and fuses. Ensure that the electrical system is normal and avoid equipment failure caused by electrical failure.

4. Check the cooling system: The cooling system of the extruder is very important. Regularly check whether the cooling water pipeline is blocked and whether the cooling water flows normally to ensure that the equipment will not overheat.

5. Check the heating system: The heating system of the extruder also needs to be checked regularly to ensure that the heater, heat medium and temperature controller are working normally. If there is damage or malfunction, replace or repair it in time.

6. Check the screw and barrel of the extruder: regularly check and clean the screw and barrel of the extruder to ensure that the surface is smooth and free of scratches and rust. At the same time, check the gap between the screw and the barrel and adjust it in time.

7. regular maintenance of the extruder: according to the use of equipment, regular overhaul and maintenance. Disassemble the equipment, clean and replace parts, eliminate hidden dangers and fatigue, and ensure the stable operation of the equipment.

The above are common maintenance methods for extruders. Through regular maintenance, the incidence of equipment failures can be reduced, equipment life can be extended, and production efficiency can be improved. At the same time, when using the extruder, the requirements of the equipment manual should be followed to avoid overload use and wrong operation.

RELATED INFORMATION

Maximizing Output with Twin Screw Roller Head Extruder Settings: A Comprehensive Guide

Maximizing Output with Twin Screw Roller Head Extruder Settings Introduction to Twin Screw Roller Head Extruders In the world of plastic processing machinery, **twin screw roller head extruders** stand out for their versatility and efficiency. These machines are designed to handle various materials, making them indispensable in the manufacturing sector. Understanding how to optimize their settings

Understanding the Benefits and Functionality of Parallel Twin Screw Extruders

Parallel twin screw extruders are specialized machines widely used in the plastic processing industry. As the name suggests, these extruders feature two parallel screws that rotate synchronously within a barrel, providing a unique method of material handling and processing. This design allows for enhanced mixing, compounding, and extrusion of a variety of materials, making them an essential tool f