2025/02

Maximizing Throughput with Twin Screw Co-Rotating Extruders: Tips and Tricks for Enhanced Performance Table of Contents 1. Introduction to Twin Screw Co-Rotating Extruders 2. Understanding Throughput in Plastic Extrusion 3. Key Factors Affecting Throughput 3.1 Material Characteristics 3.2 Screw Design and Configuration 3.3 Temperature and P

2025/01

Understanding Twin Screw Co-Rotating Extruders: A Key to Advanced Plastic Processing

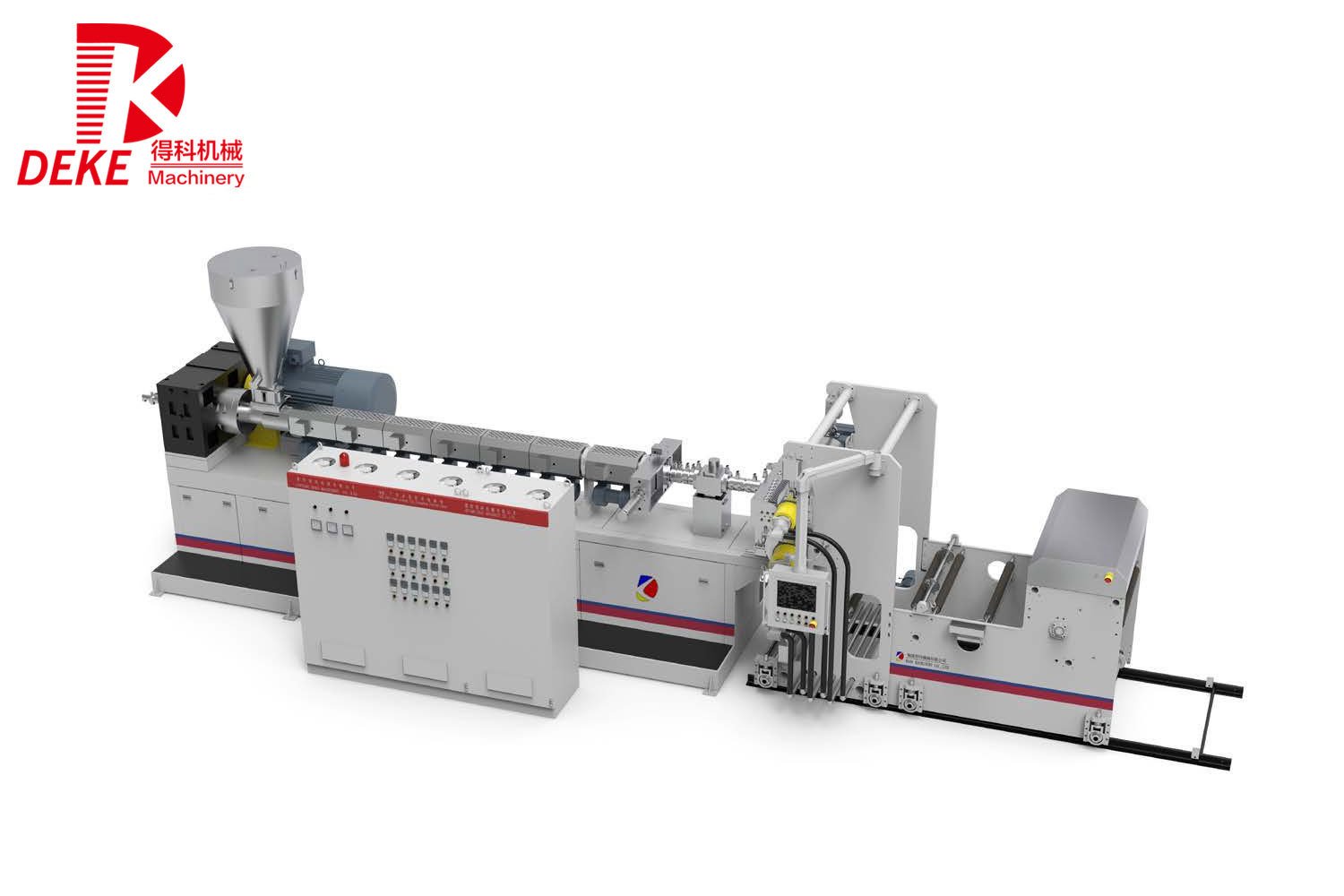

Twin screw co-rotating extruders are highly regarded in the plastic processing machinery sector due to their versatility and efficiency. These machines consist of two intermeshing screws that rotate in the same direction, allowing for improved material mixing, melting, and conveying. The co-rotation design enhances the interaction between the plastic material and the screws, resulting in efficient

2025/01

Unlocking the Potential of Micro Twin Screw Extruders in Plastic Processing

Micro twin screw extruders are advanced machinery designed specifically for the precise processing of polymer materials. These extruders utilize two intermeshing screws, which rotate in the same direction, to efficiently mix, melt, and extrude plastic compounds. This technology is particularly beneficial in the manufacturing of high-quality materials, as it allows for a uniform distribution of add

2025/01

Enhancing Product Formulation with Micro Twin Screw Extruder Technology Table of Contents 1. Introduction to Micro Twin Screw Extruder Technology 2. The Science Behind Micro Twin Screw Extrusion 2.1 Mechanical Design and Functionality 2.2 Importance of Screw Configuration 3. Advantages of Micro Twin Screw Extruder Technology 3.1 Efficient Material Processing 3.2 Enhanced Product Qu

2025/01

Unlocking the Potential of the Micro Twin Screw Extruder in Plastic Processing

Micro twin screw extruders are specialized machines designed to process a wide range of materials, particularly in the field of plastic manufacturing. These extruders utilize two intermeshing screws to convey, mix, and shape materials, making them an ideal choice for applications that require high precision and control. The compact size of micro twin screw extruders allows them to be used in labor

2025/01

Micro Twin Screw Extruders: Pioneering the Future of Circular Economy in Plastic Manufacturing

Micro Twin Screw Extruders: Pioneering the Future of Circular Economy in Plastic Manufacturing Table of Contents 1. Introduction to Micro Twin Screw Extruders and Circular Economy 2. Understanding Micro Twin Screw Extruders 2.1. Key Components and Functions 2.2. Types of Micro Twin Screw Extruders 3. The Role of Micro Twin Screw Extruders in Circular Economy 3.

2025/01

Understanding HIPS Sheet Extruders: A Key Component in Plastic Manufacturing

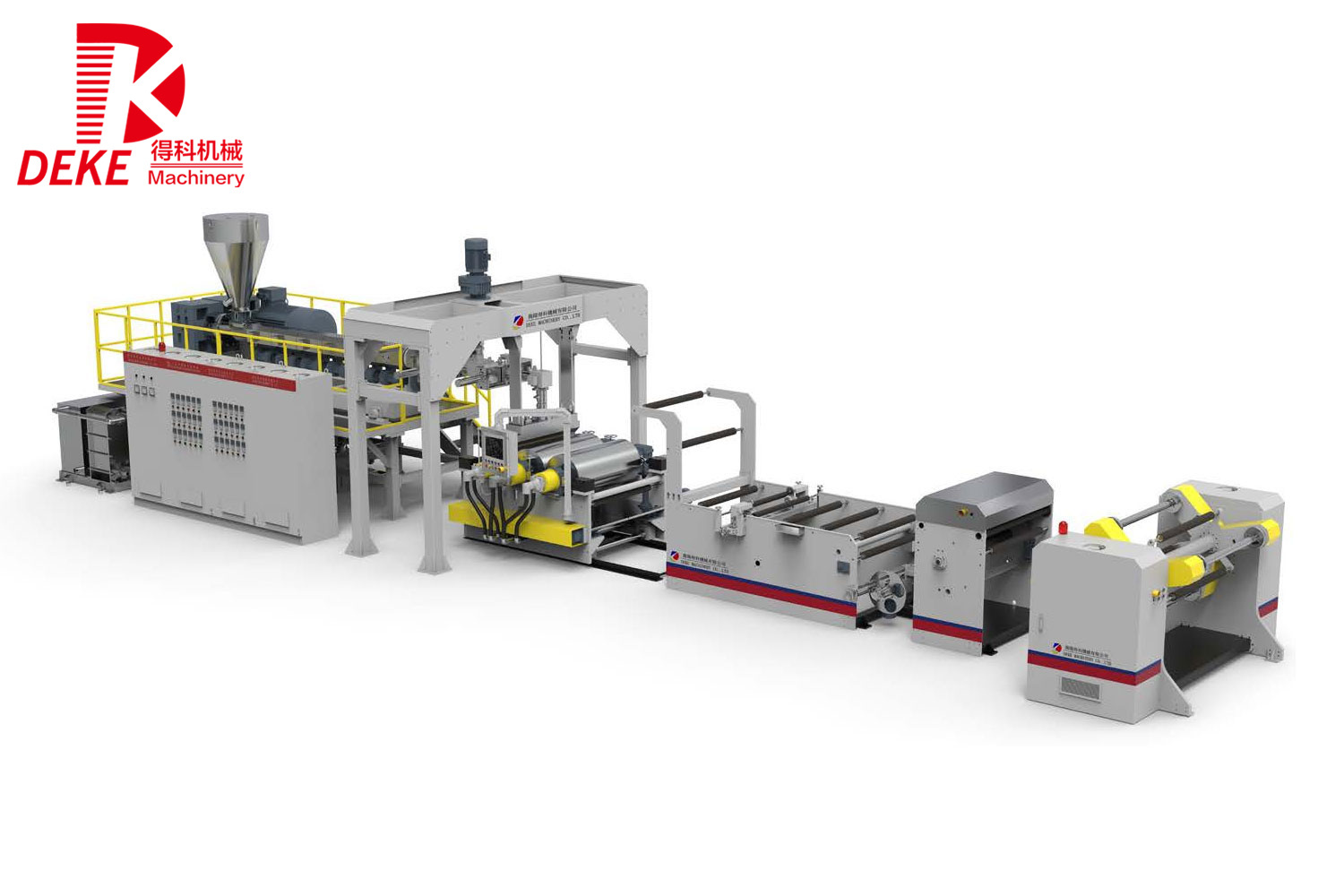

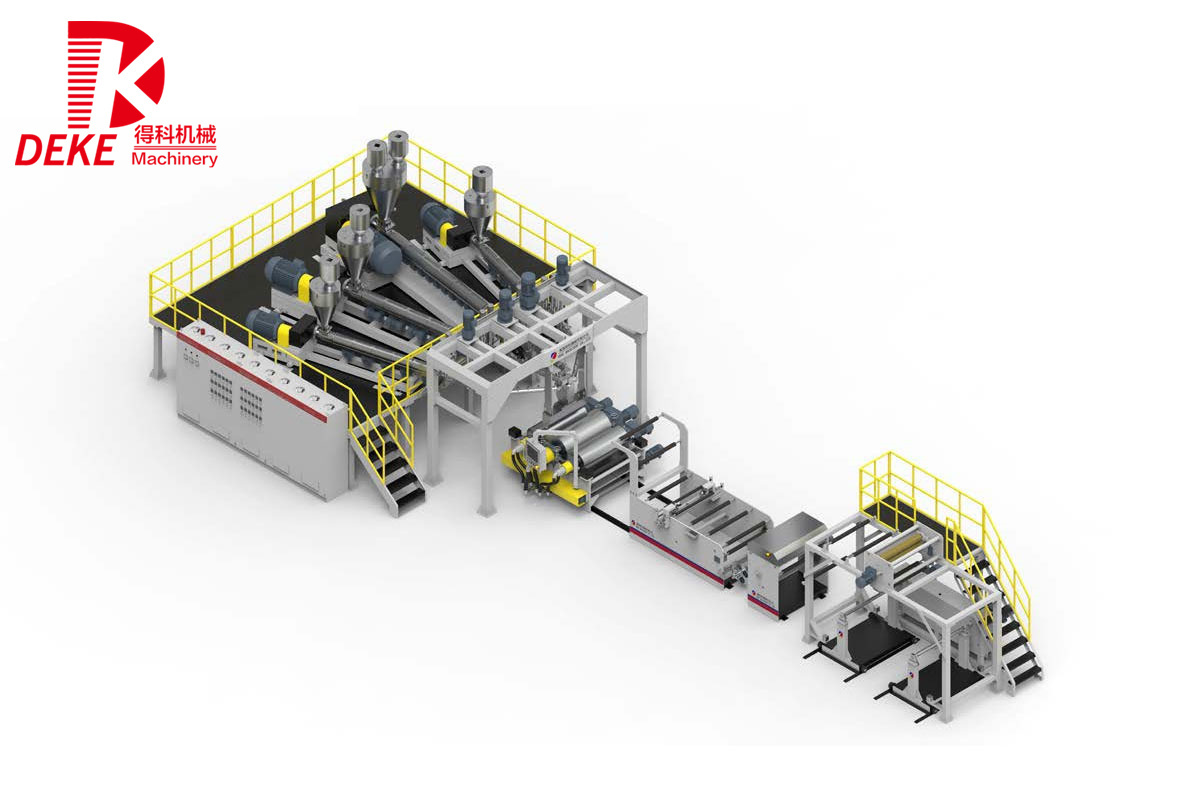

HIPS, or High Impact Polystyrene, is a versatile thermoplastic widely used in various applications, including packaging, consumer goods, and automotive components. The manufacturing of HIPS sheets involves a critical piece of equipment known as the HIPS sheet extruder. Understanding how these extruders work can provide valuable insights into the plastic processing industry and its implications for

2025/01

Exploring the Benefits of HIPS Sheet Extrusion for Plastic Processing: A Comprehensive Guide

Exploring the Benefits of HIPS Sheet Extrusion for Plastic Processing Table of Contents 1. Introduction to HIPS Sheet Extrusion 2. What is HIPS? 3. Advantages of HIPS Sheet Extrusion 3.1 Strength and Durability 3.2 Versatility in Applications 3.3 Cost-Effectiveness 3.4 Ease of Processing 3.5 Environmental Considerati

2025/01

Understanding HIPS Sheet Extruders: Key Insights for Professionals

High Impact Polystyrene (HIPS) is a widely used thermoplastic material known for its strength, durability, and versatility. HIPS sheet extruders are specialized machines designed to produce sheets of HIPS through a continuous extrusion process. Understanding the operation and benefits of HIPS sheet extruders can greatly enhance the efficiency and quality of your production line. The extrusion proc

2025/01

Maximizing Efficiency: The Crucial Role of HIPS Sheet Extruders in Modern Manufacturing

Maximizing Efficiency: The Crucial Role of HIPS Sheet Extruders in Modern Manufacturing Table of Contents Introduction to HIPS and Its Applications What Are HIPS Sheet Extruders? Benefits of Using HIPS Sheet Extruders How HIPS Sheet Extruders Work Applications of HIPS Sheets in Various Industries Choosing the Right HIPS Sheet Extruder for Your Needs Maintenance and Opt

RELATED INFORMATION

Choosing the Right Parallel Twin Screw Extruder for Your Needs

Choosing the Right Parallel Twin Screw Extruder for Your Needs Table of Contents Understanding Parallel Twin Screw Extruders Applications and Industries Using Extruders Key Components of a Parallel Twin Screw Extruder Considerations for Choosing the Right Extruder Different Types of Parallel Twin Screw Extruders Performance Evaluation of Extruders Maintenance and Suppo

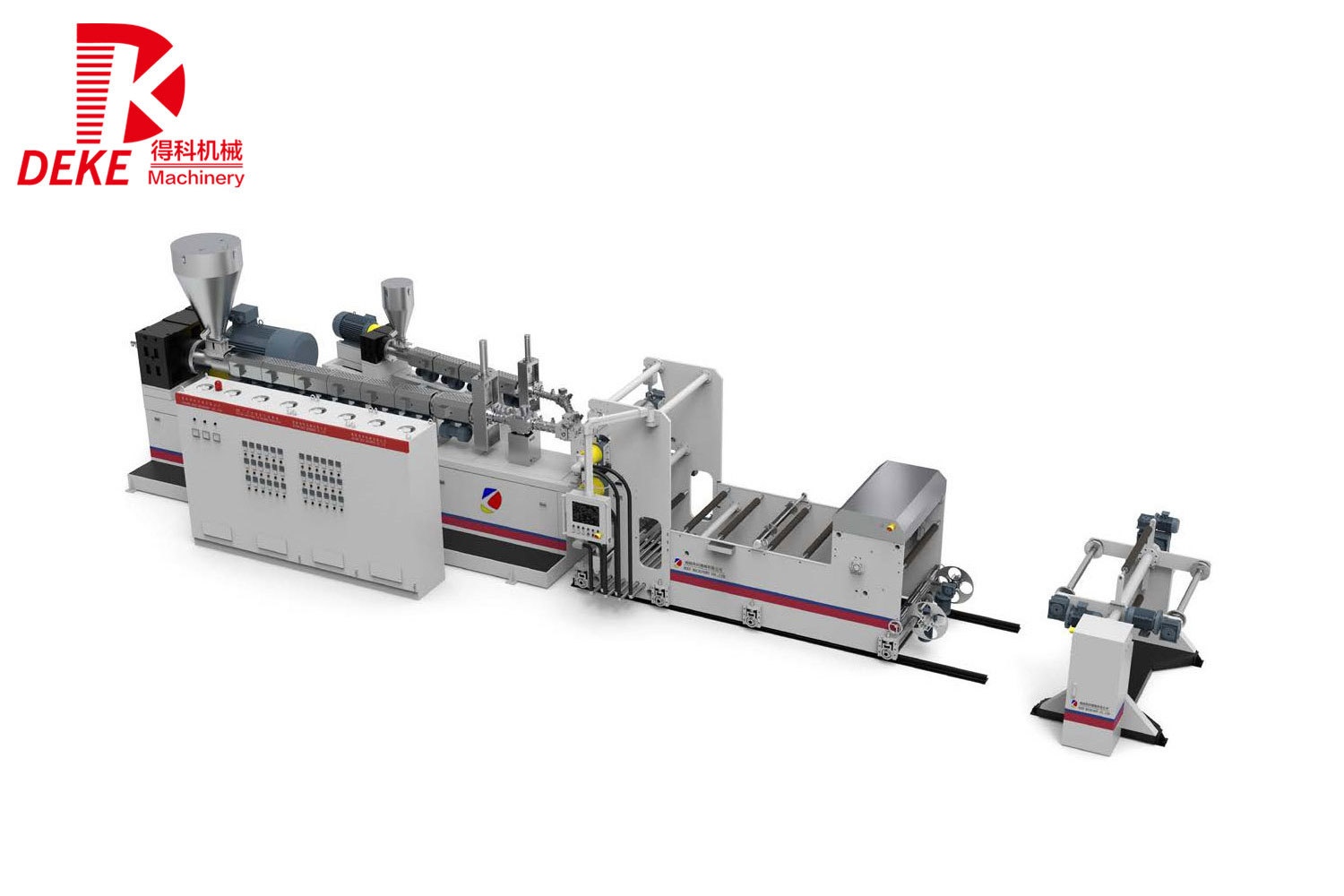

Understanding the Benefits and Applications of Parallel Twin Screw Extruders

In the realm of plastic processing machinery, the parallel twin screw extruder stands out as a versatile and effective solution for a variety of applications. This type of extruder is characterized by two screws that run parallel to each other, allowing for efficient melting, mixing, and compounding of materials. The design of the parallel twin screw extruder enables a uniform and consistent outpu