Contact Us

E-mail :

desmond@deke-machinery.com

Whatsapp/Wechat:

86-13422480688

Address:Didu Town, Jieyang City, Guangdong Province

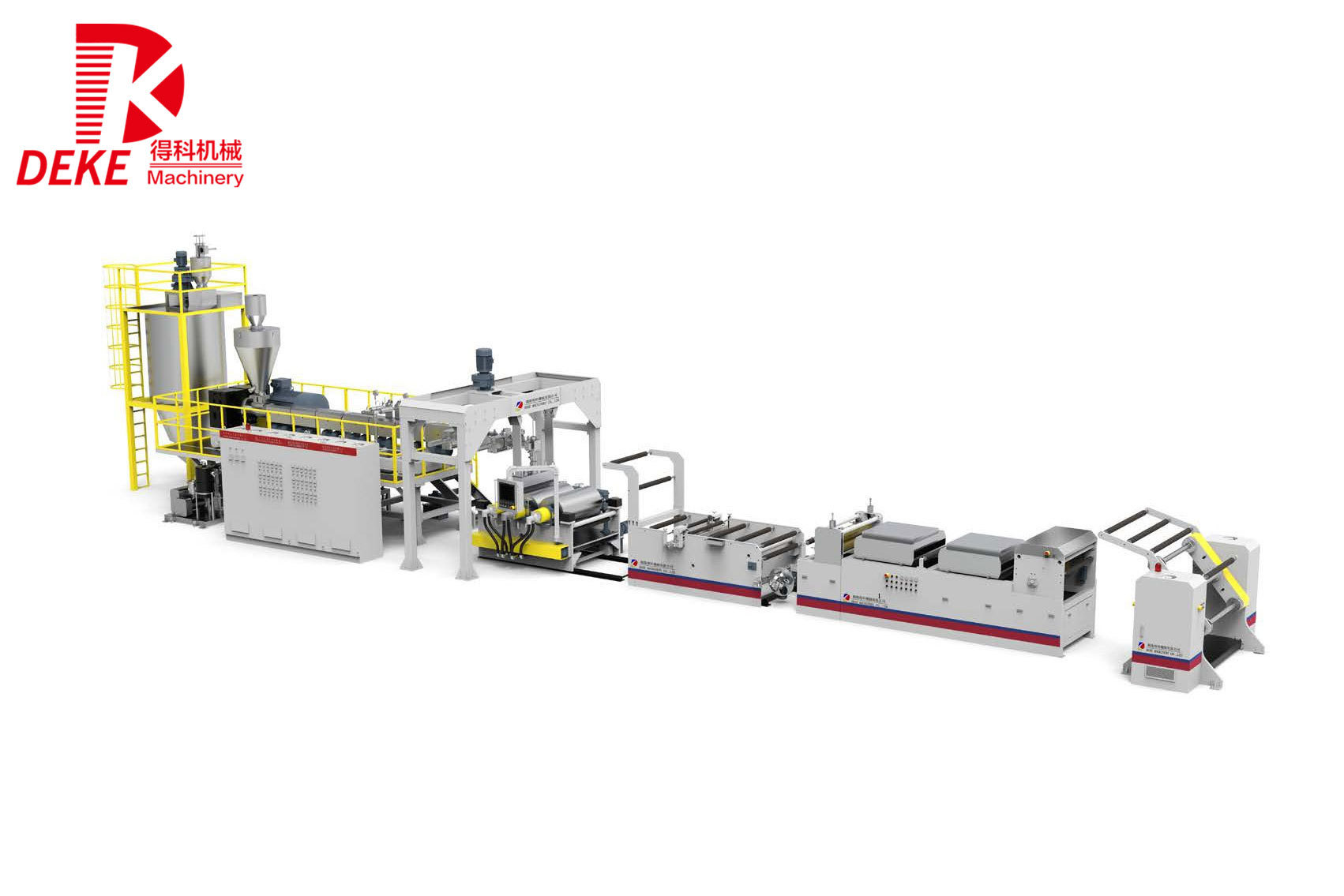

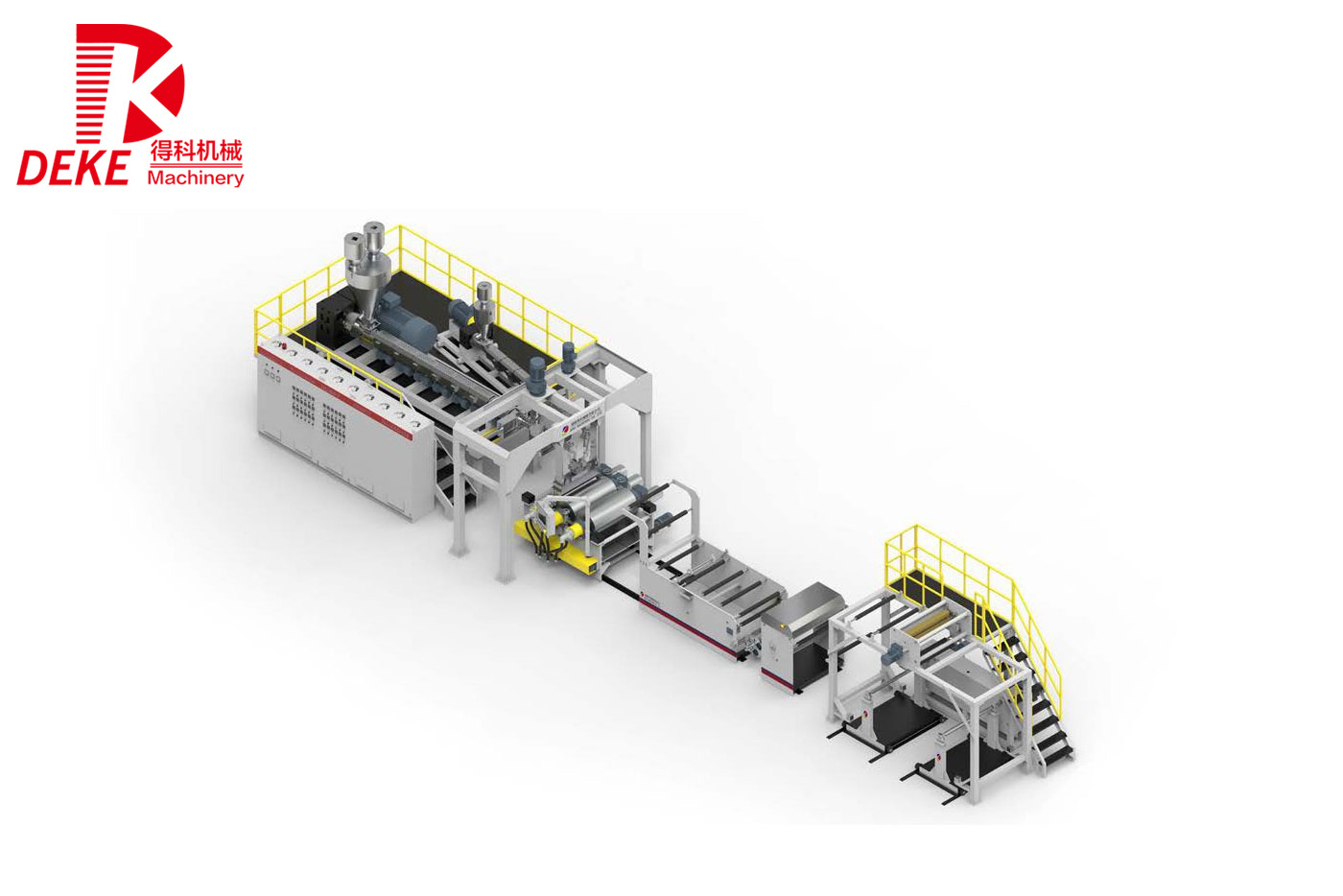

PP / HIPS Sheet Co-Extruder High Efficient Series

Summary: Professional production of PP,PS,PET,PC,ABS,PLA,EVOH and other single/multi-layer plastic sheet extrusion equipment

- Commodity name: PP / HIPS Sheet Co-Extruder High Efficient Series

- Product Details

-

This machine through optimize the structure of Melt Pump and T-Die and its distributor, to achieve the precise ratio of each layer, uniform thickness, low inner stress between inner layers, especially suitable for the products have special requirements or reduce the cost of production

Machine main characteristics as following:

# Higher output capacity, very suitable for Big Order Product.

# High precise ratio of each inner layer

# High uniformity each inner layer.Main model and parameter table of this machine:

Main Data Sheet

螺杆直径

Screw Dia. (mm)片材宽度

Sheet Width (mm)片材厚度

Thickness (mm)标准产量

Stand Output (Kg/h)整机功率

Total power (KW)外形尺寸

Dimension (m)整机重量

Total weight (Tons)DKW110/66 -1100

Ø110/ Ø66

≤780mm

0.3~2.0mm

450kg/h

205kw

16.5×4.6×4m

27T

DKW125/66 -1100

Ø125/ Ø66

≤780mm

0.3~2.0mm

650kg/h

280kw

19×4.8×4m

29T

DKW125/80/66 -1100

Ø125/ Ø80/ Ø66

≤780mm

0.3~2.0mm

700kg/h

350kw

19×5.5×4m

35.5T

DKW140/95/80 -1100

Ø140/ Ø95/ Ø80

≤780mm

0.3~2.0mm

1000kg/h

480kw

20×5.6×4m

39T

Note: For more updated parameters, please refer to the machine configuration.

Case Presentation

HIPS Sheet Co-Extruder High Efficient is an advanced sheet production equipment.

In terms of material applicability, HIPS Sheet Co-Extruder High Efficient can handle two common and important plastic materials: PP (polypropylene) and HIPS (high-impact polystyrene). Through co-extrusion technology, the advantages of the two are perfectly combined. For PP, its good mechanical properties, heat resistance and chemical stability can be utilized; while HIPS provides excellent impact resistance.

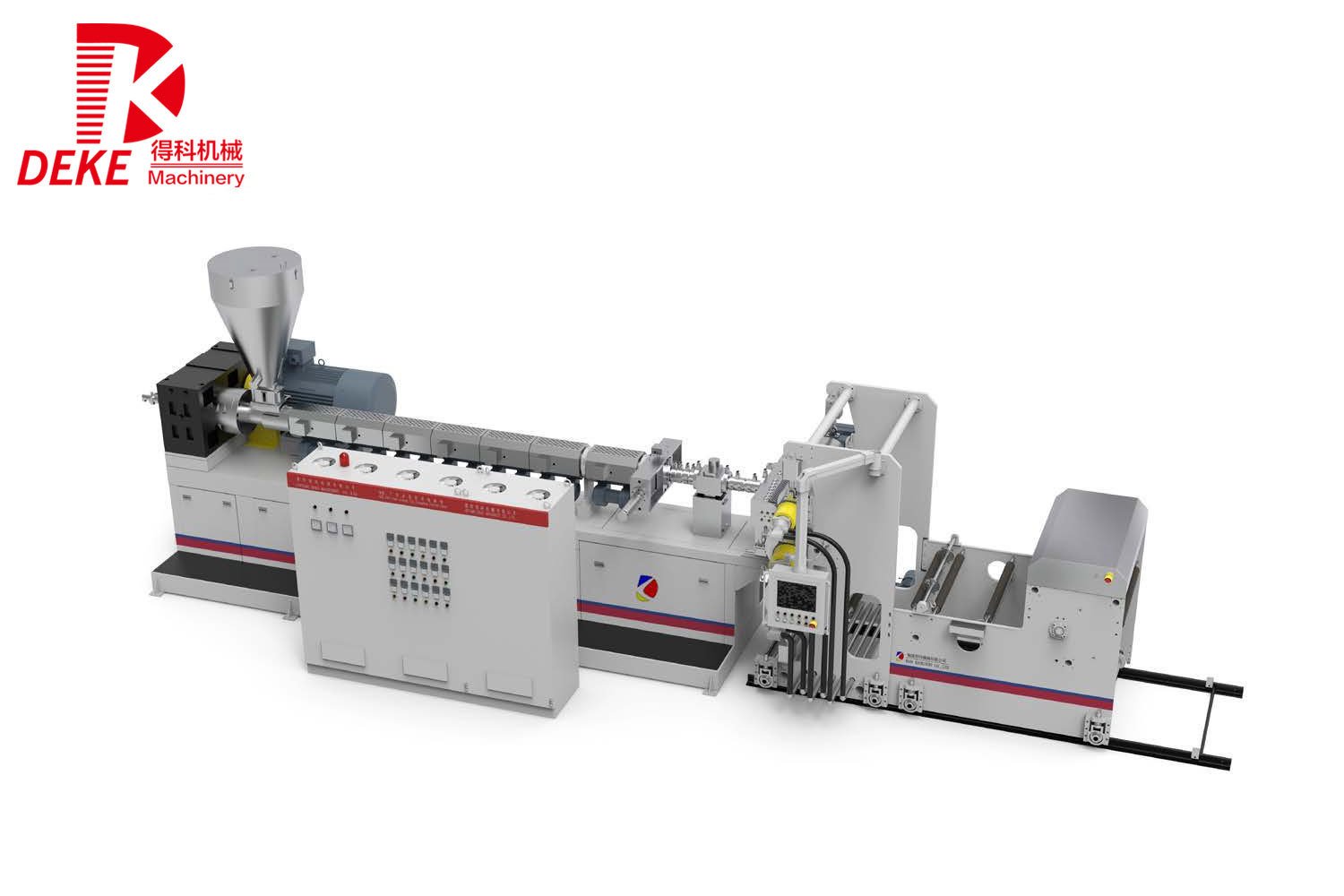

From the perspective of extrusion process, the equipment is highly efficient. Its unique screw design ensures uniform mixing and stable conveying of raw materials during extrusion, and precise temperature control makes the melting state of the material just right, reducing energy loss.

In terms of production quality, HIPS Sheet Co-Extruder High Efficient can accurately control the thickness and surface flatness of the sheet, and the produced sheet has uniform thickness and smooth surface, meeting various high-end application requirements. Whether it is the requirements for barrier properties and appearance in the field of food packaging, or the demand for sheet physical properties in the field of electronic packaging, we can provide high-quality sheet solutions, greatly improving production efficiency and product quality, and are the ideal choice for sheet manufacturers.

Key words:

Online Inquiry

Note: Please leave your email address and our professionals will contact you as soon as possible!